What is a train signaling system?

The traffic lights we often see in the city centre are essential systems to maintain traffic order on roads full of cars. The simple rule of stopping at red light and starting at green light creates safety and smooth traffic flow on the road. Similarly, trains and control centers communicate and there is a train signaling system that responds to various operating conditions.

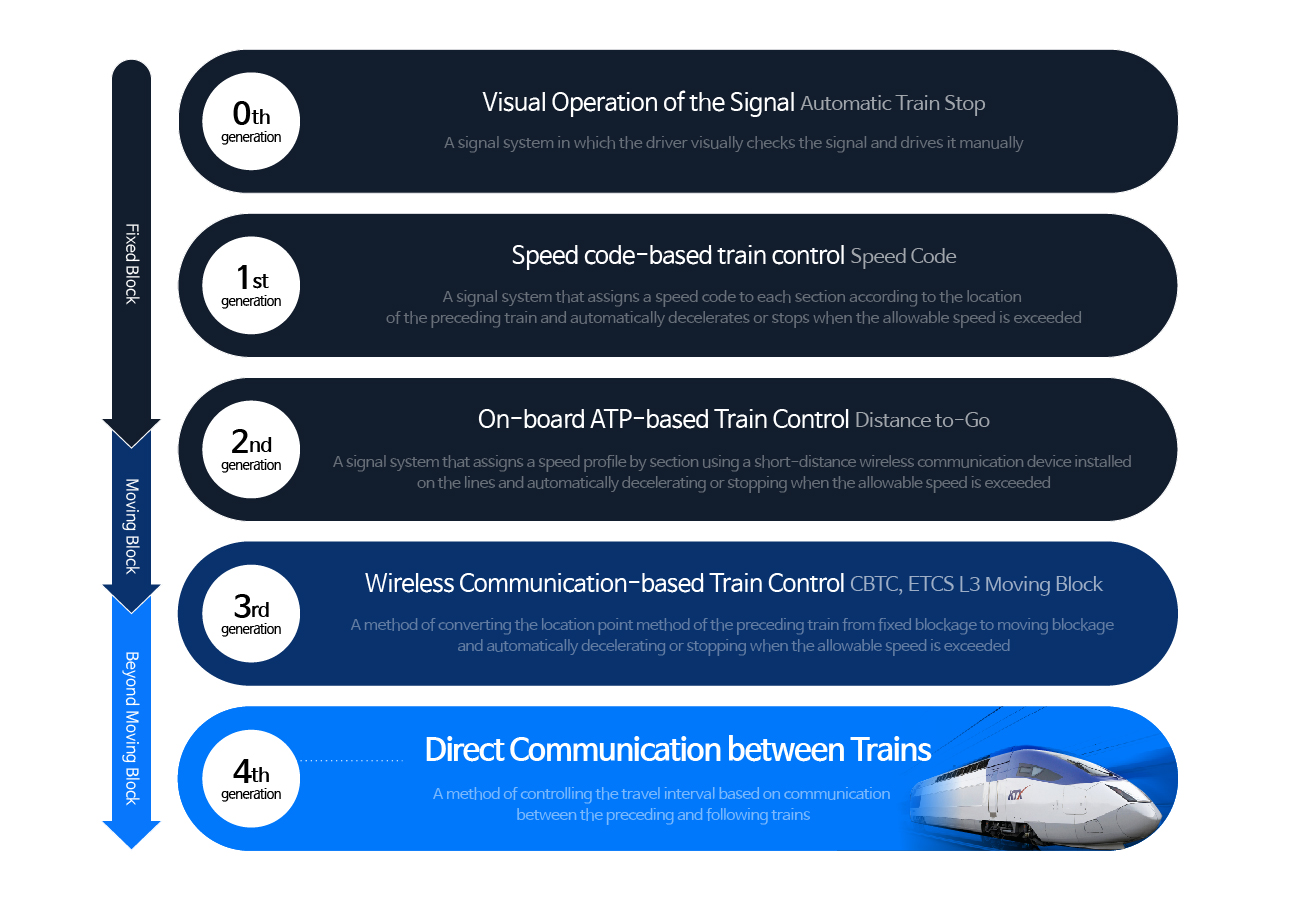

However, the signaling system for traffic order in the city center and the signaling system for trains are very different. Unlike the road signaling system that controls several means of transportation, the train signaling system applies a method in which only one train operates in a single block section. In addition, unlike the road signaling system, which relies on the driver’s judgment by looking at the traffic lights, the train signaling system operates through a safety system that determines the safety conditions such as traffic lights, route switches, crossings, and circuits that determine the condition of the track. As trains gradually become faster, they have developed from a method of judging through signals along the routes to an automatic train signaling system between all stations that transmit information through wireless communication methods.

The train signaling system is a key system of train operation that controls the speed of the train to prevent crash and collision, and derailment of the train and performs route conversion to change the train’s driving route. Unlike cars, trains run along a set route, so it seems simpler than the car’s signaling system, but all systems such as traffic lights, route switches, crossings, circuits that determine the condition of the track, and safety equipment are organically connected and operated. In particular, as the train becomes faster, it becomes difficult for the driver to directly check and respond to the signal, so it operates in a way that transmits a signal to the running train.

It is very important to manage the train signaling system and build a train signaling system with high safety because failure or error in the train signaling system is likely to lead to major accidents such as train collisions and derailments. In fact, the collision accident at Sangwangsimni Station (2014) and the KTX derailment accident on the Gangneung Line (2018) occurred due to the failure of the train signaling system in Korea.

It is essential to build an advanced train signaling system not only for safety but also for increasing transportation capacity. If a more sophisticated signaling system is built through technology development, it is possible to effectively input as many trains as possible on a set route. In addition, it can help solve problems such as urban population concentration and saturation of existing lines without additional route expansion or new train input.

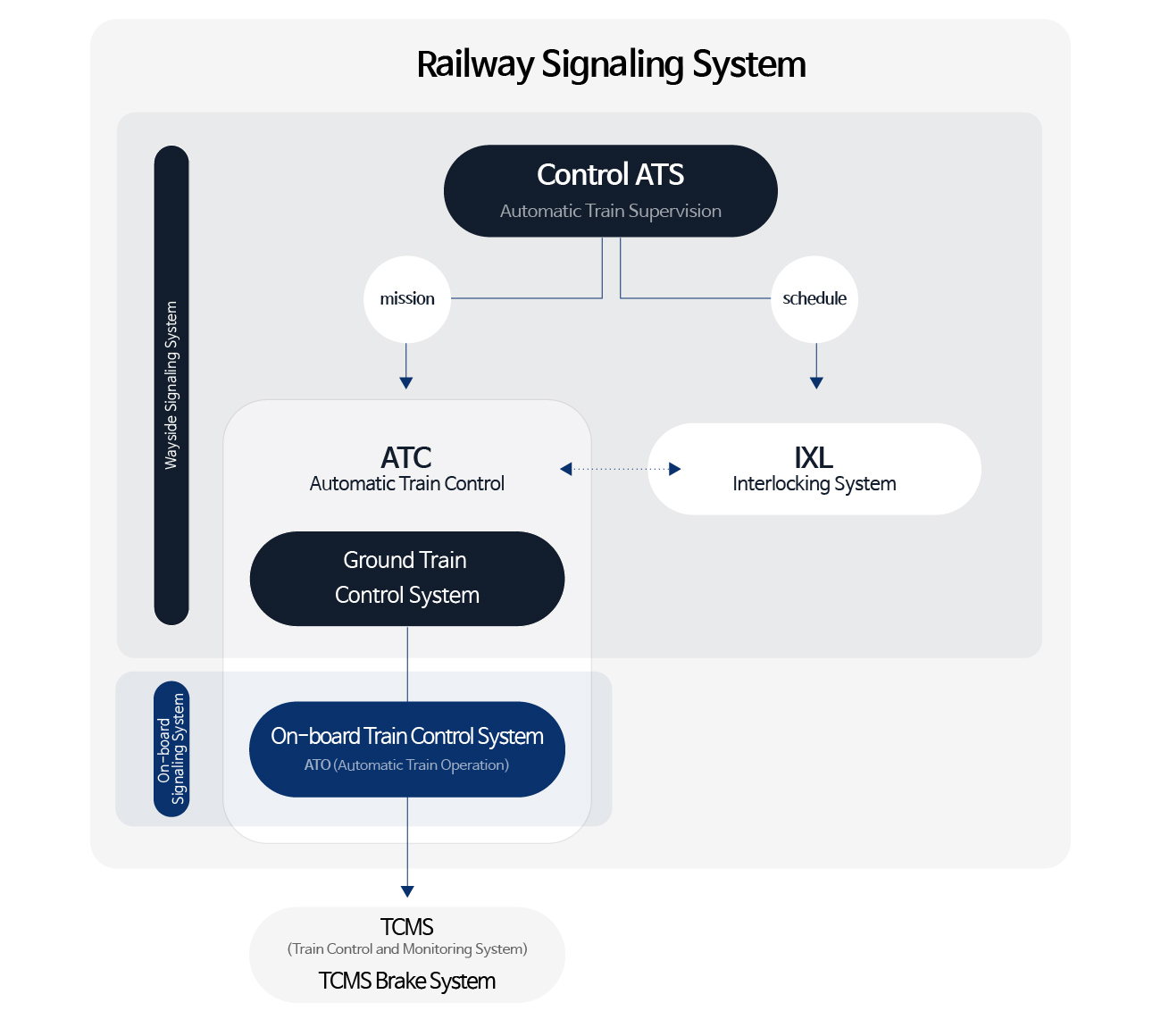

Construction of the railway signaling system

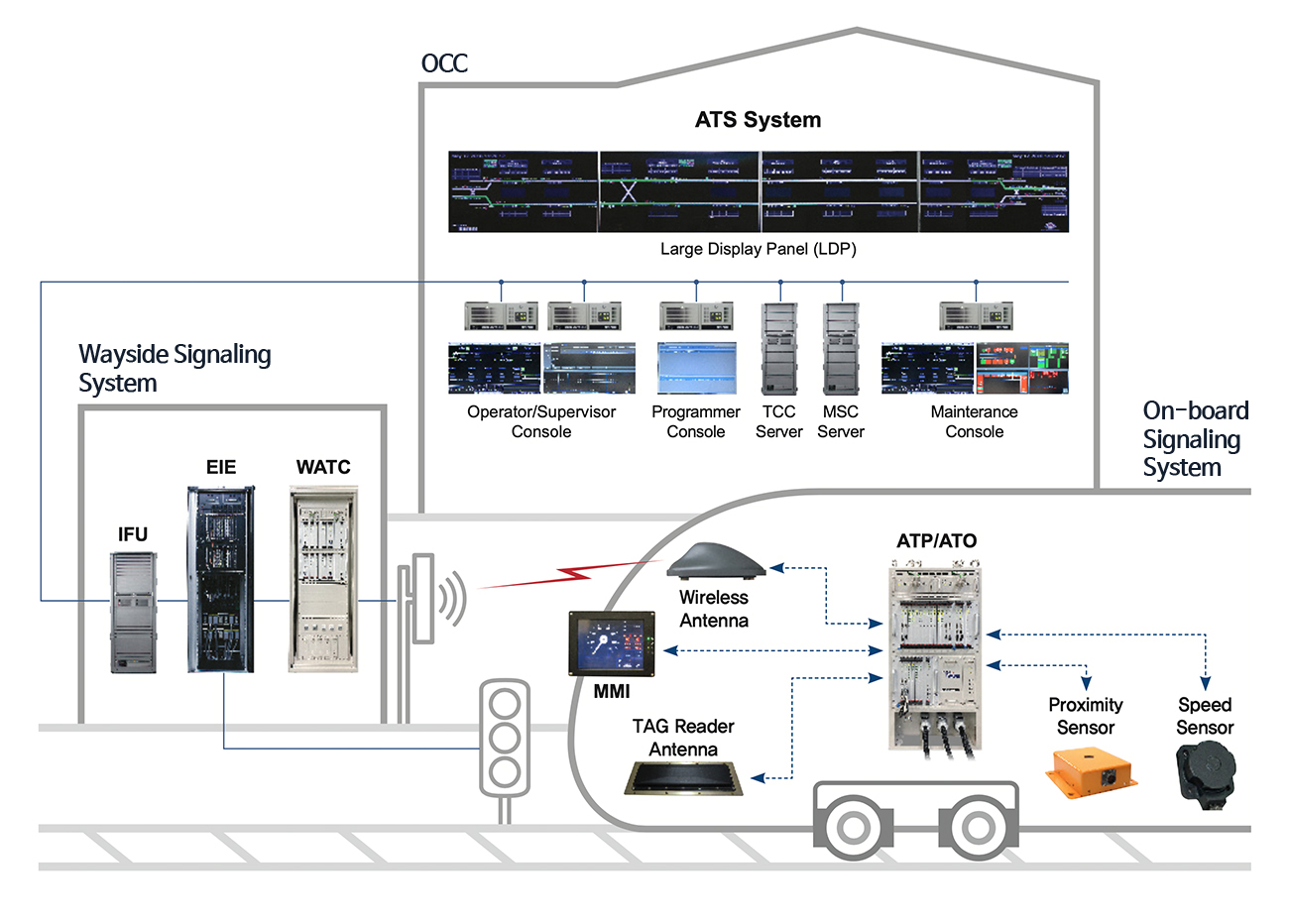

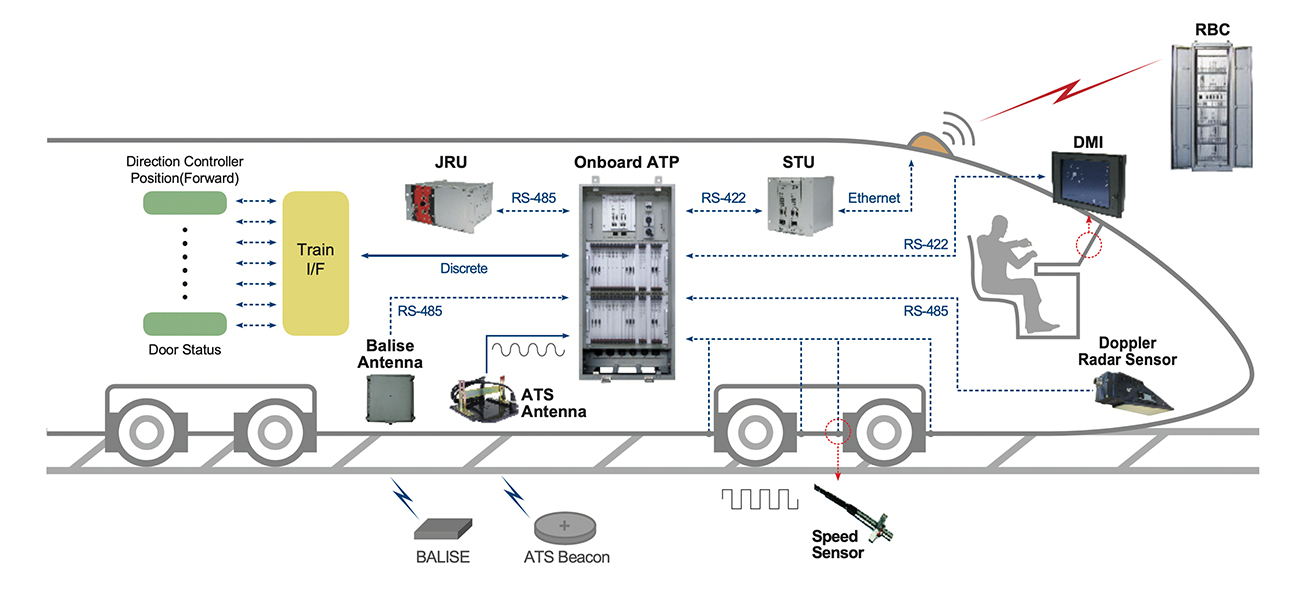

The railway signaling system is largely divided into the wayside signaling system and the on-board signaling system. The wayside signaling system includes a control, interlocking system and an automatic train control, and the on-board signaling system includes an on-board train control. Control refers to a system that remotely monitors and controls all trains and on-site signaling system by exchanging train operation information with interlocking system and automatic train control. The interlocking system is a system that operates by being connected to a signal, a route switch, and a track circuit to safely perform train route control according to a schedule. The automatic train control is divided into speed step and distance-to-go according to the control method, and the speed step is divided into ATS and ATC, and the distance-to-go is divided into ATP, D-ATC, and CBTC.

Types of automatic train control

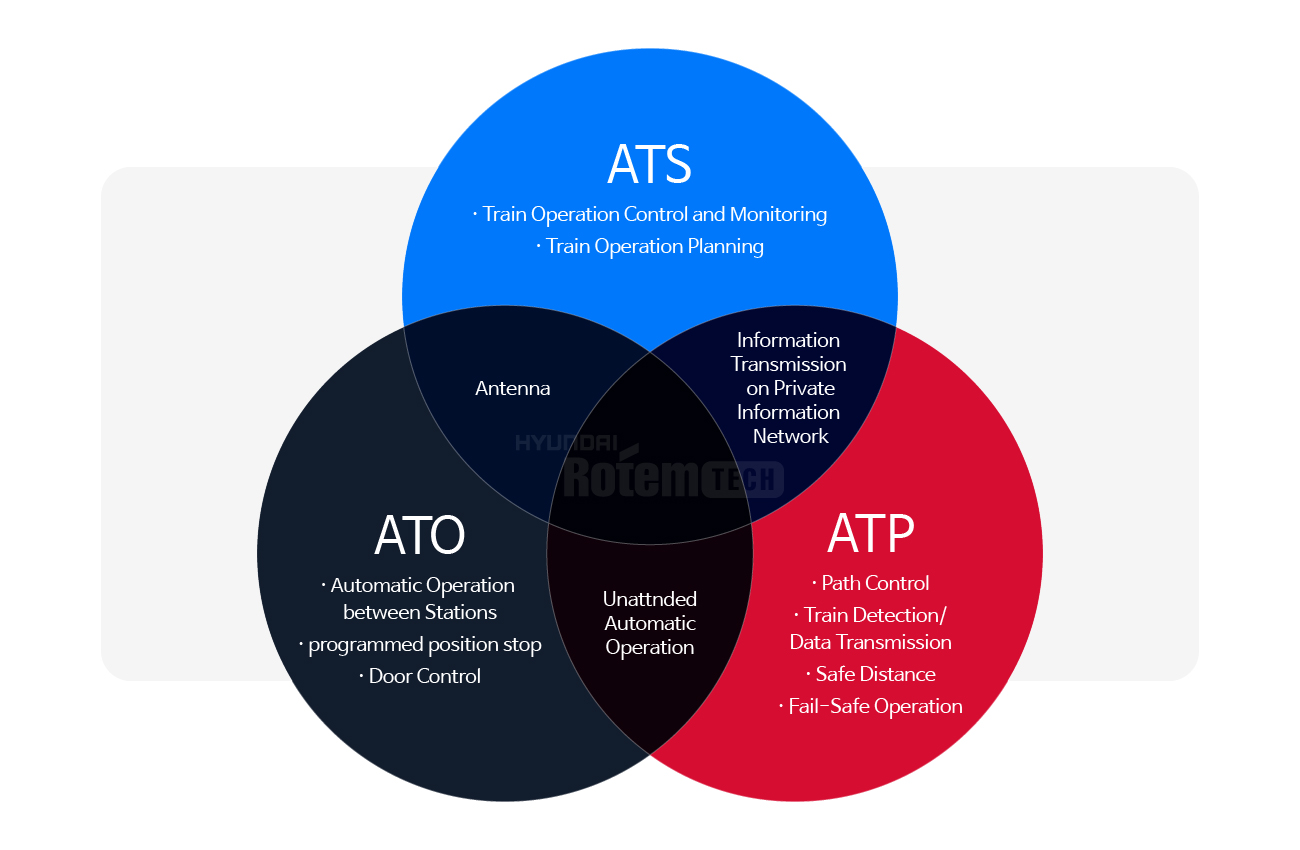

ATS(Automatic Train Stop) – A system that sends a deceleration warning or automatically stops the train through an ATS grounder installed between the rails.

ATC(Automatic Train Control) – A system that receives the train speed limit signal transmitted through the rail from the train and automatically controls it below the speed limit. It is divided into S-ATC of speed step and D-ATC of distance-to-go.

ATP(Automatic Train Protection) – A system that controls the speed of a train based on the location of the train and controls the train based on data on the distance to the train in front and data on route conditions.

ATO(Automatic Train Operation) – ATP-based train autopilot system. A system that can operate trains fully automatically, such as automatically operating between stations within the speed limit, and opening and closing the doors at stations, etc.

CBTC(Communication-Based Train Control) – A method in which the on-board and the wayside signaling system communicate wirelessly and control the operation. Because two-way communication is possible, the OCC and the train exchange information about the train condition in real time, and the OCC continuously identifies the information of the front and rear trains and controls the operation.

Trend of train signaling system development in Korea

As of late, countries with developed railways are attempting to change the agent of train signal control from the ground to on-board through T2T-based (Train to Train) technology, a system where trains communicate directly with one another for operational flexibility and scalability, and to further reduce the train intervals through cooperation between intelligent trains without involvement of OCC and drivers.

‘Shift2Rail’, the European Union’s railway industry innovation project, is conducting research on virtual connectors that enable direct communication between trains to dramatically increase the amount of train transport. Virtual connection technology aims to allow two or more trains to move simultaneously through a virtual coupling without physical coupling within very close distances.

The British railway company RSSB (Rail Safety and Standards Board) has also been working on the ‘Closer Running’ project with the goal of increasing the amount of train transport since 2017. The project is researching implementation of vehicle-to-vehicle communication control technology, intelligent autonomous driving technology, separation and coupling technology of trains while operating, predictable train braking technology, and fast and reliable track switching technology by eliminating ground equipment.

China is promoting R&D on a train-centered train control system that controls driving intervals and track branches based on communication between preceding and following trains. The National Natural Science Foundation of China and Jiaotong University in Beijing are developing a communication-based interval control prototype corresponding to ETCS (European Train Control System) with the goal of improving the reliability of the train control system. Japan is developing a train that can dynamically change its operation schedule according to the prediction of train delays and control the gap with the front train.

Trend of train signaling system development in Korea

Korea’s train signaling system has been promoting technology development focusing on the localization of existing systems. Hyundai Rotem is taking the lead in developing a Korean train signaling system suitable for various types of trains such as high-speed trains, electric trains, and trams in consideration of Korea’s communication environment.

‘KTCS-M on-board/ground system’, a Korean urban railway signaling system developed by Hyundai Rotem, is a system that safely controls trains with continuous two-way data communication between on-board and wayside using ISM Band’s Wi-Fi method or railway-only wireless communication method (LTE-R). All automatic operation levels, including unmanned train operation (UTO), can be operated so that it can efficiently operate urban railways.

* KTCS: Korea Train Control System: Korean Train Signaling System

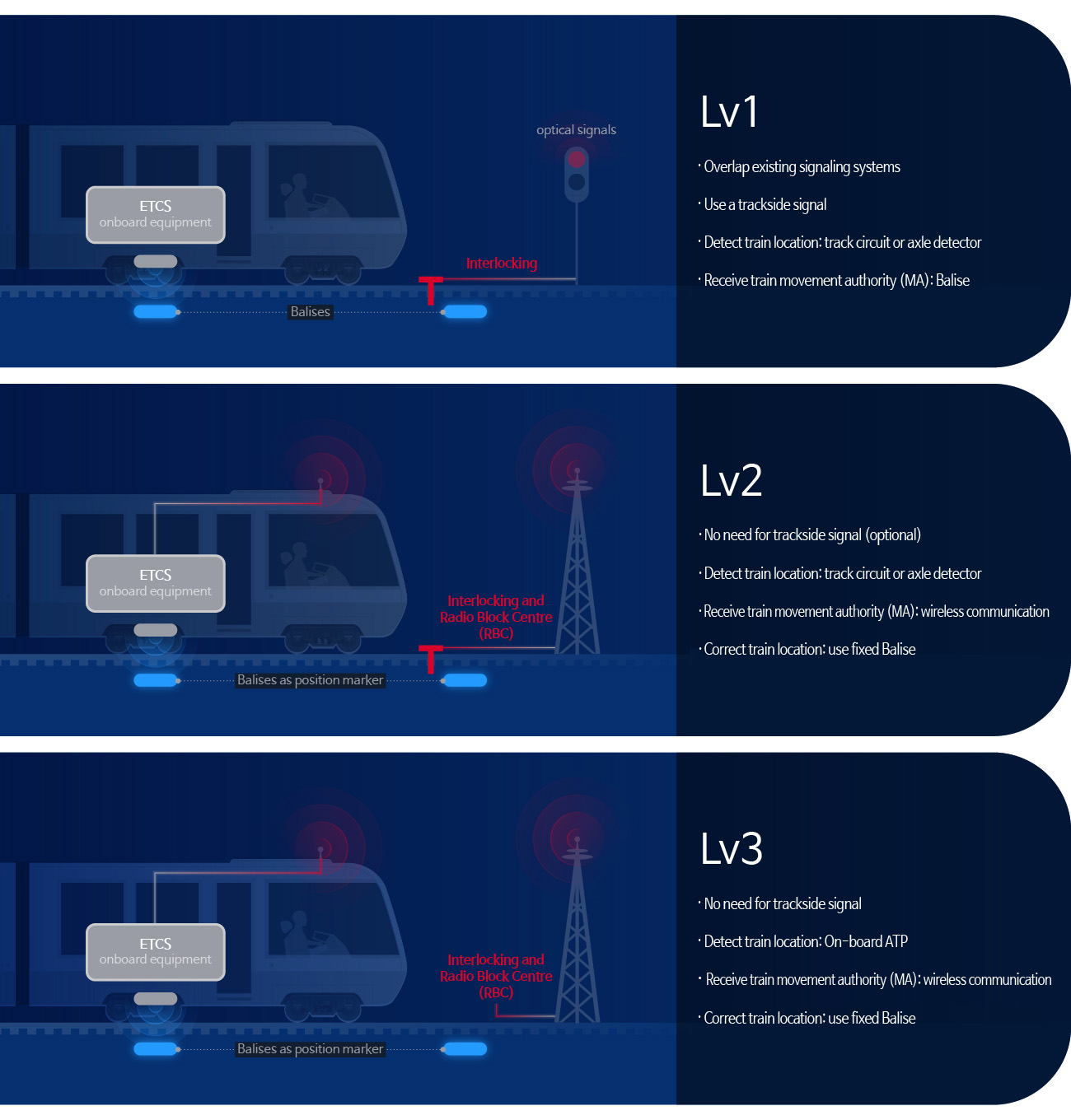

KTCS-2 on-board system is a train signaling system for general and high-speed railways developed by Hyundai Rotem. It is an ATP system that meets the Korean LTE-R communication-based train control system standard. With the development of KTCS-2, the train signaling system has been standardized in Korea, and it is very meaningful that it can build a Korean signaling system compatible with any route. The system provides operability on South Korean routes as well as interoperability on European Train Control System (ETCS) Level 1 and Level 2 standards for European and other regional routes, and can safely operate and manage trains with high availability. Hyundai Rotem is currently promoting mass production after verifying the performance of the developed KTCS-2 train signaling system through a pilot operation in the 180km section of the Iksan~Yeosu Expo on the Jeolla Line.

Meanwhile, the ETCS Level 3 on-board signaling system supporting automatic operation, which is the latest train signaling system technology (tentative name “KTCS-3”) that Hyundai Rotem is promoting localization, is an ATP/ATO integrated on-board system that meets European railway standards. It is a signal system that allows train control using only radio communication (LTE-R) without using track circuits in high-speed railway operating environments (350 km/h speed band). It is a technology that supports automatic train operation (GoA2) to provide higher route efficiency and railway transportation power than ETCS L2 through real-time train tracking and train spacing adjustment. It is also expected to improve interoperability and minimize ground equipment since ATP (ETCS Level 1) currently built on railway routes and LTE-R-based KTCS-2, which is promoting mass production after the pilot project can be interoperated. Hyundai Rotem completed the development of this technology with the National Railroad Corporation as a national R&D project in 2020, and is pursuing technology and performance verification by 2024.

Therefore, Hyundai Rotem is leading R&D in the Korean train signaling system field with the goal of localizing the train signaling system. It is not only introducing technologies that have already been developed, but also introducing the latest technologies in Korea in line with global trends, and is conducting proprietary development for overseas exports. Hyundai Rotem will expand its position in the global railway market by actively utilizing new technologies such as autonomous driving and artificial intelligence in the railroad field and securing proprietary technologies.