Hydrogen Reformer

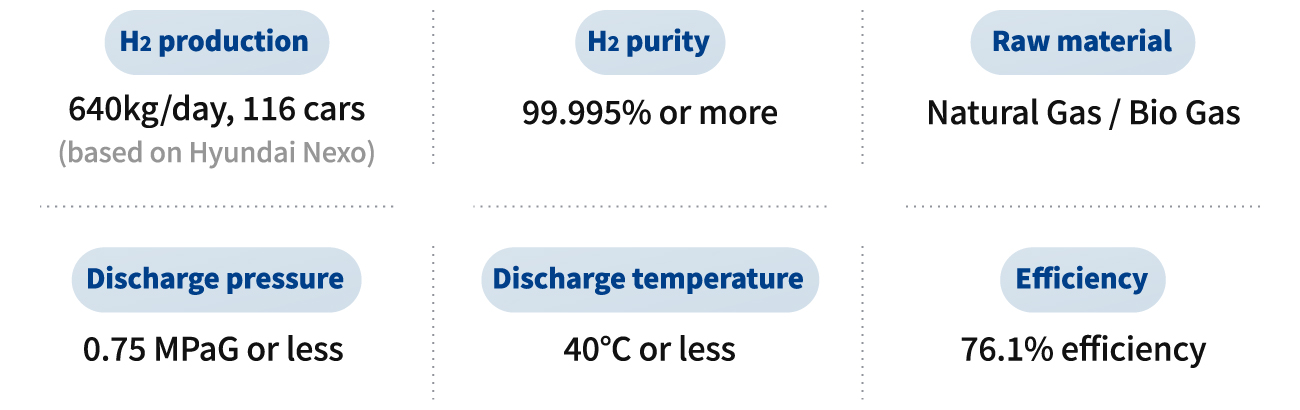

Hyundai Rotem’s hydrogen reformer has the capacity to produce 300N㎥ per hour and 640kg per day of hydrogen with a purity of 99.995% or more despite its size which is only slightly larger than a 40ft container.

640kg of hydrogen is the capacity to refuel 116 hydrogen cars (Nexo), which means that hydrogen production capacity is good even though it is a small facility. Hyundai Rotem has not only secured core technology for hydrogen reformer production, but also produces key facilities for building hydrogen refueling infrastructure through thorough quality control in its dedicated factory.

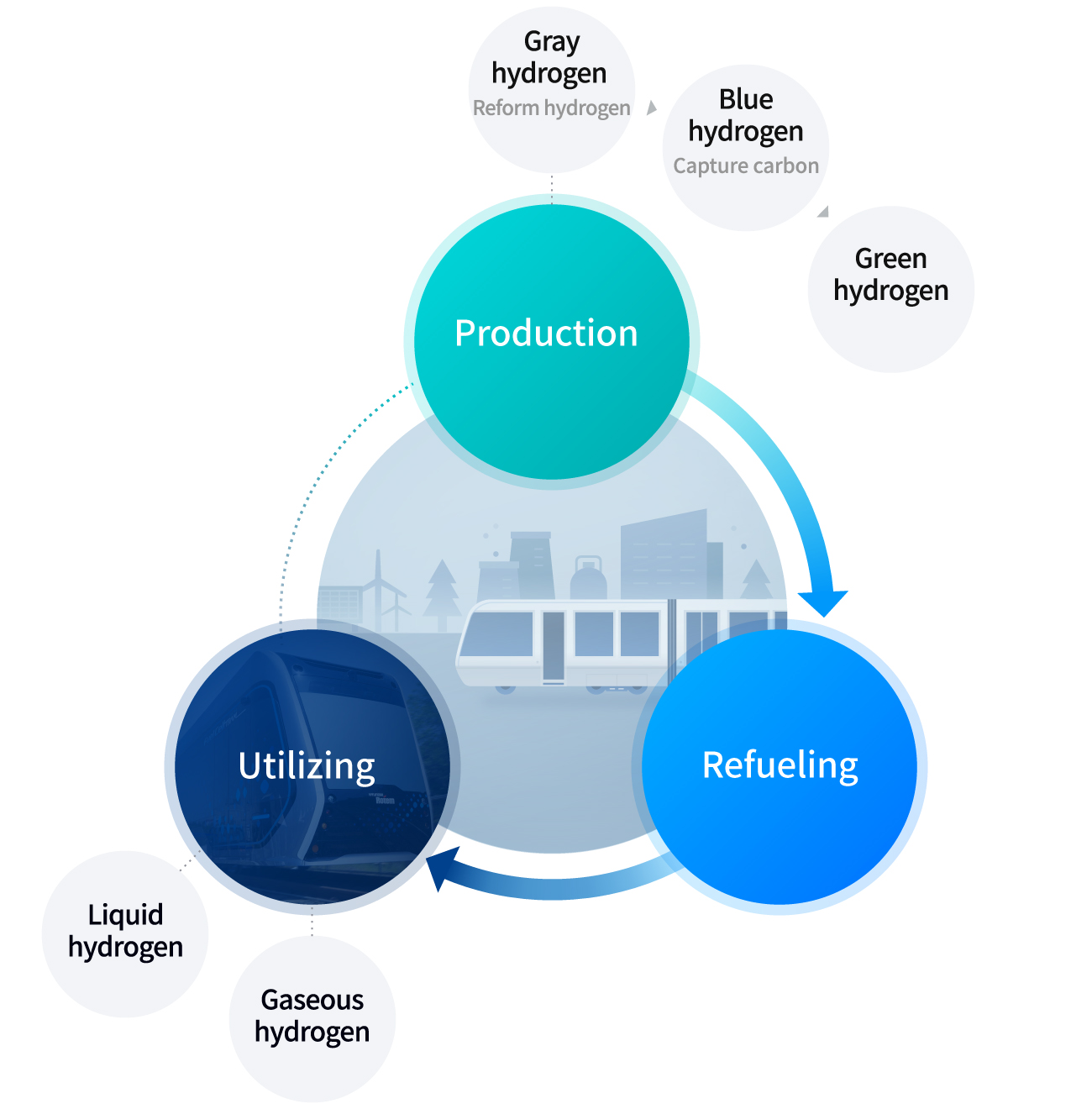

This gives us the ability to supply both off-site hydrogen refueling station or on-site hydrogen refueling station according to customer requirements.

Characteristics of Hydrogen Reformer

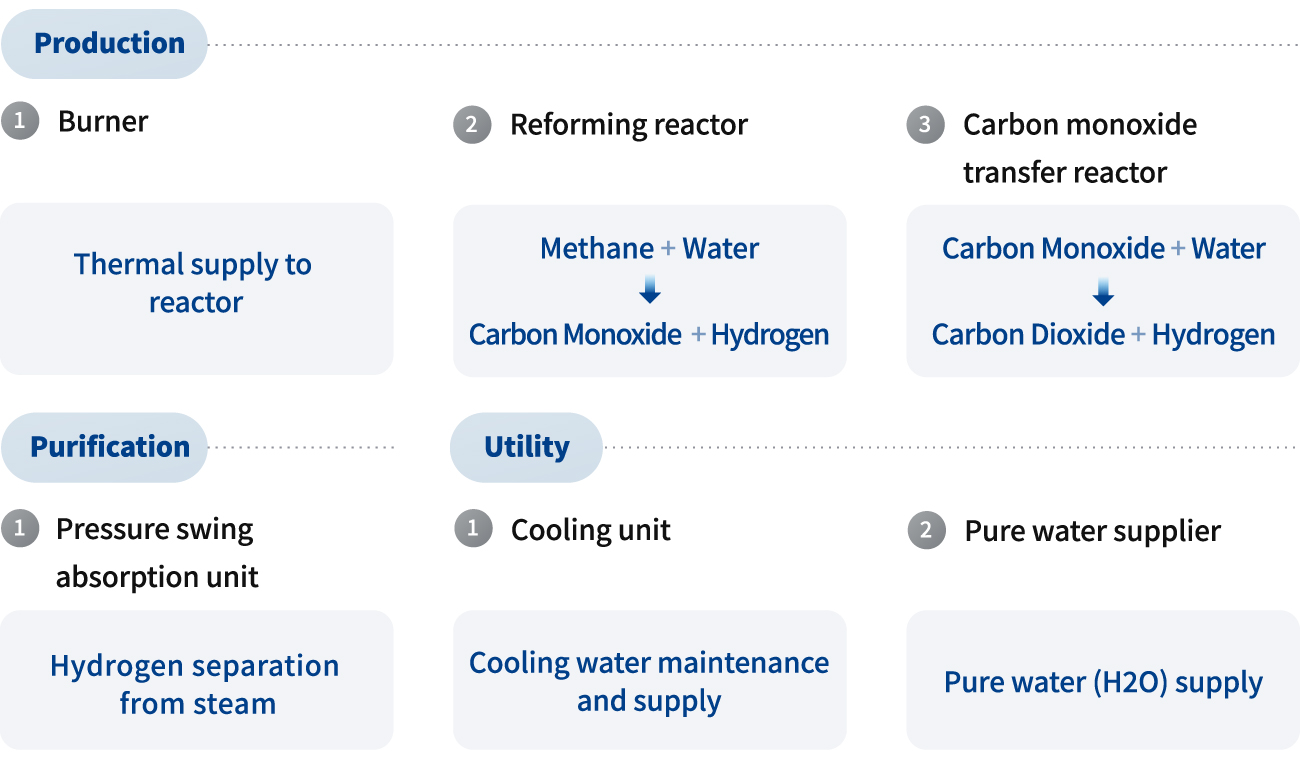

Hyundai Rotem’s hydrogen reformer removes natural gas compressed through a gas compressor from the desulfurization tower, then mixes it with pure water and inserts it into the reforming reactor. The natural gas and pure water are reformed into carbon monoxide and hydrogen by the reforming reactor. The remaining carbon monoxide and pure water in the reforming reactor are ultimately reformed into carbon dioxide and hydrogen through the carbon monoxide transfer reactor. Subsequently, impurities are eliminated by the pressure swing absorption unit (PSA Unit) to produce a high-purity hydrogen. The produced hydrogen is carried through tube trailers or to hydrogen stations for use in needed areas.

The biggest advantage of a hydrogen reformer is that it can be used directly by producing hydrogen from a hydrogen demander by adding a device that connects the hydrogen reformer to the existing Natural gas or bio gas supply chain. In other words, hydrogen distribution costs can be reduced by installing it directly where the hydrogen is needed.

Project Records

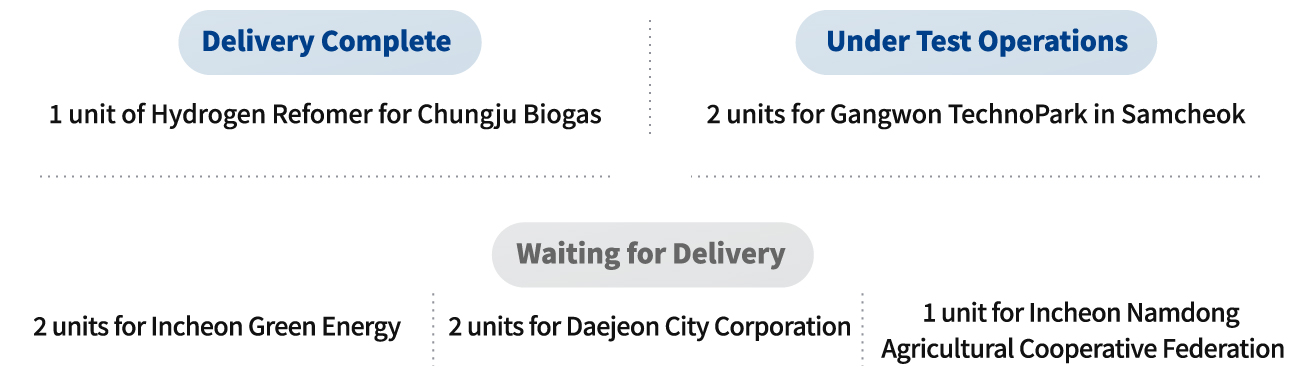

Hyundai Rotem is working on a supply project for a hydrogen reformer in cooperation with various local governments in South Korea based on its technology.

We completed the delivery of one hydrogen reformer using biogas to Chungju, South Korea. The hydrogen reformer to be supplied to Samcheok has been manufactured and will be delivered and we are working to expand the hydrogen infrastructure.