Hydrogen Storage, Hydrogen Shipping Center

The hydrogen shipping center is a hydrogen distribution hub that is essential for the hydrogen supply and distribution process. It is responsible for storing the produced hydrogen and loading it into the special hydrogen carrier called tube trailer to transporting hydrogen and supplying it to a hydrogen refueling station.

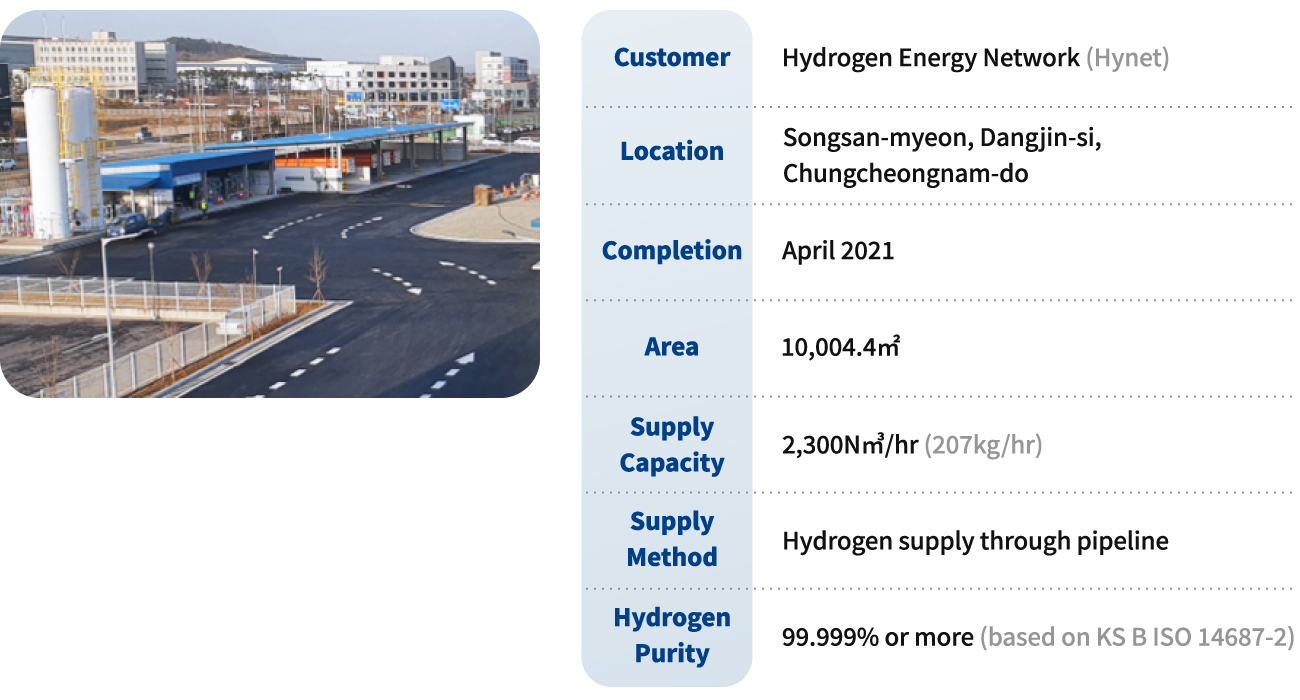

View and overview of Hynet Hydrogen Shipping Center in Dangjin, Korea

Hydrogen Utilization, Hydrogen Refueling Station

Hyundai Rotem is striving to expand the optimum hydrogen infrastructure required by customers beyond the limits of space. We respond to various needs of customers with off-site hydrogen refueling station and on-site hydrogen refueling station and we eliminate blind spots for hydrogen refueling through the mobile hydrogen refueling station. In addition, we provide a safe and comfortable hydrogen refueling environment based on excellent compatibility through self-developed dispenser with improved usability and durability.

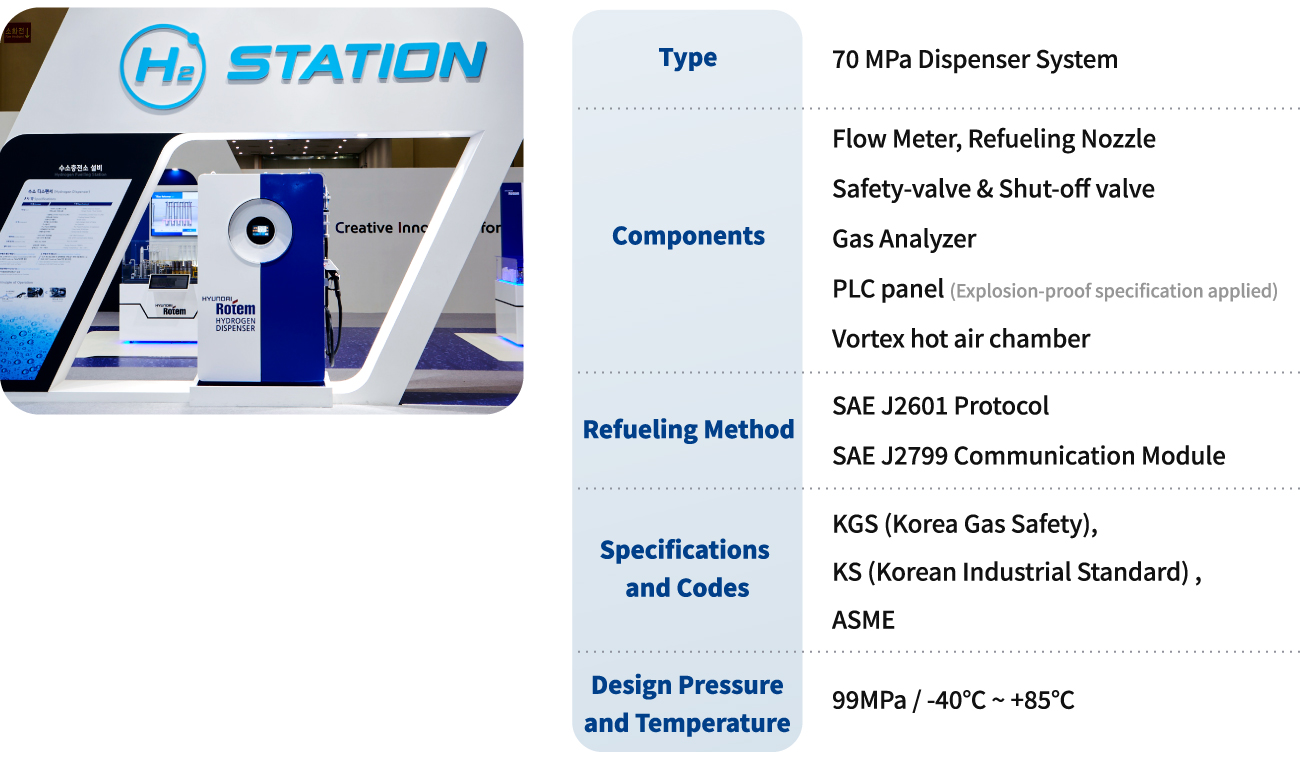

Hydrogen Dispenser

Mobile Hydrogen Refueling Facility

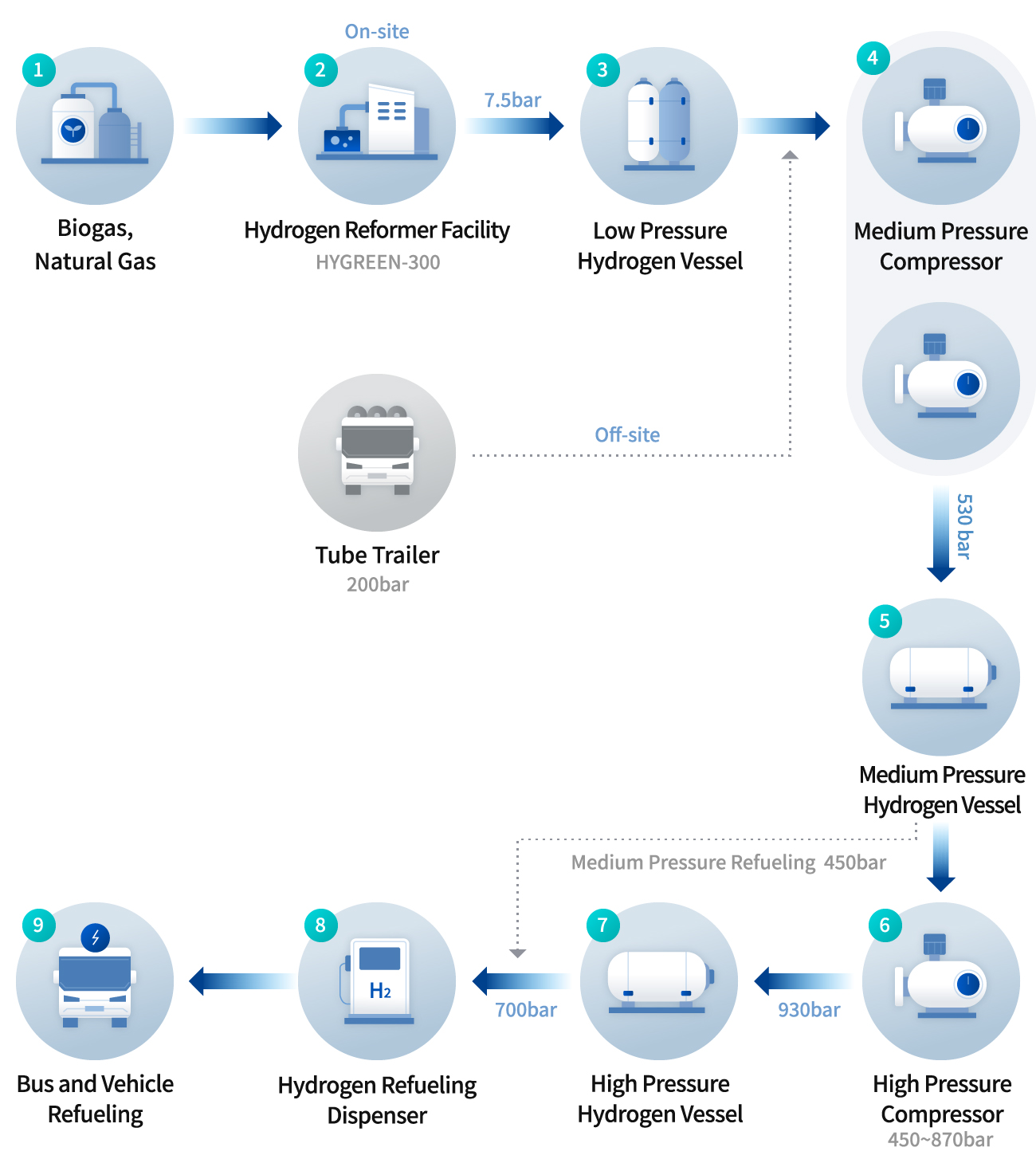

Process of Hydrogen Refueling Station

On going R&D Projects

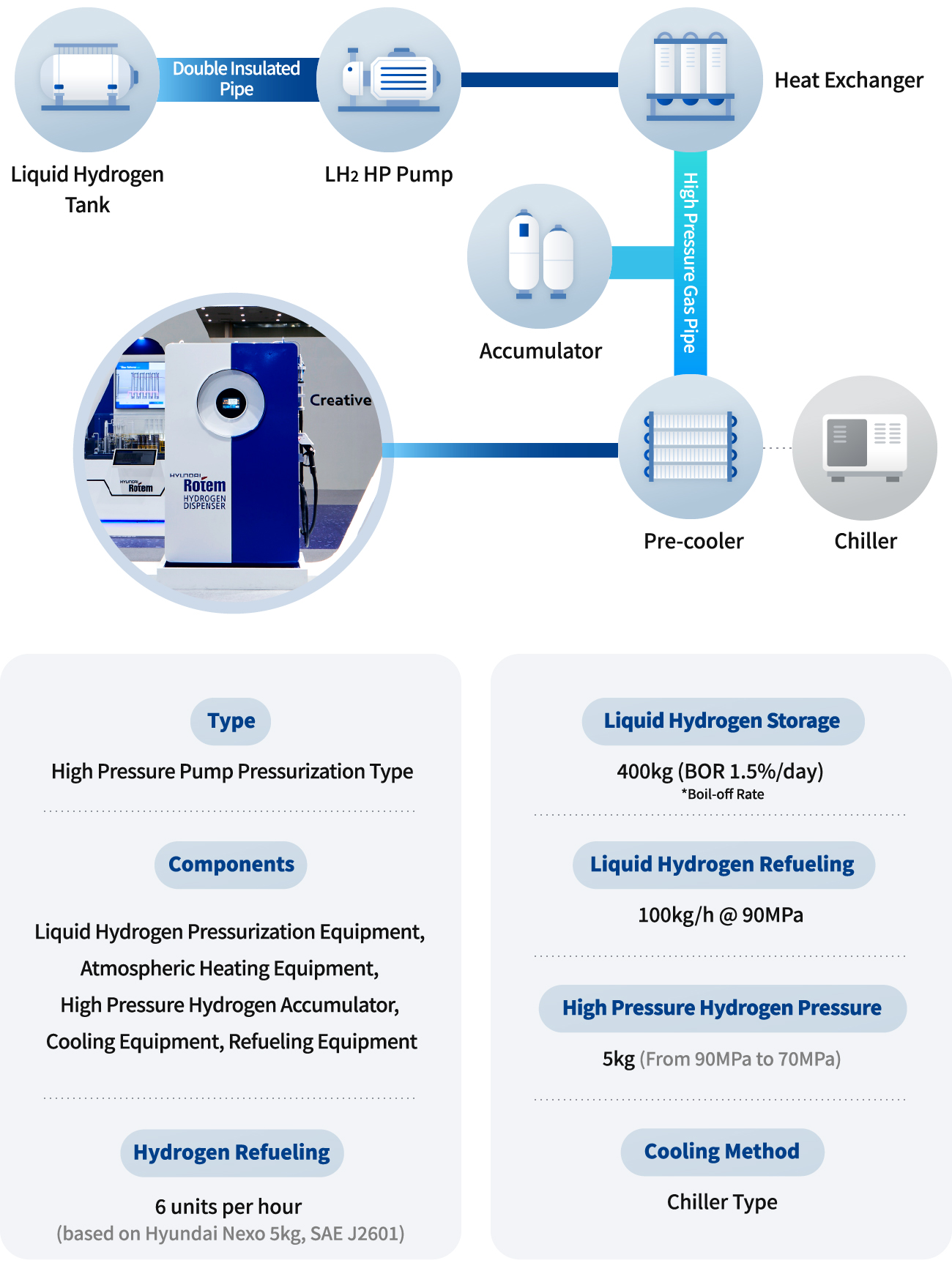

Liquified Hydrogen Refueling Station

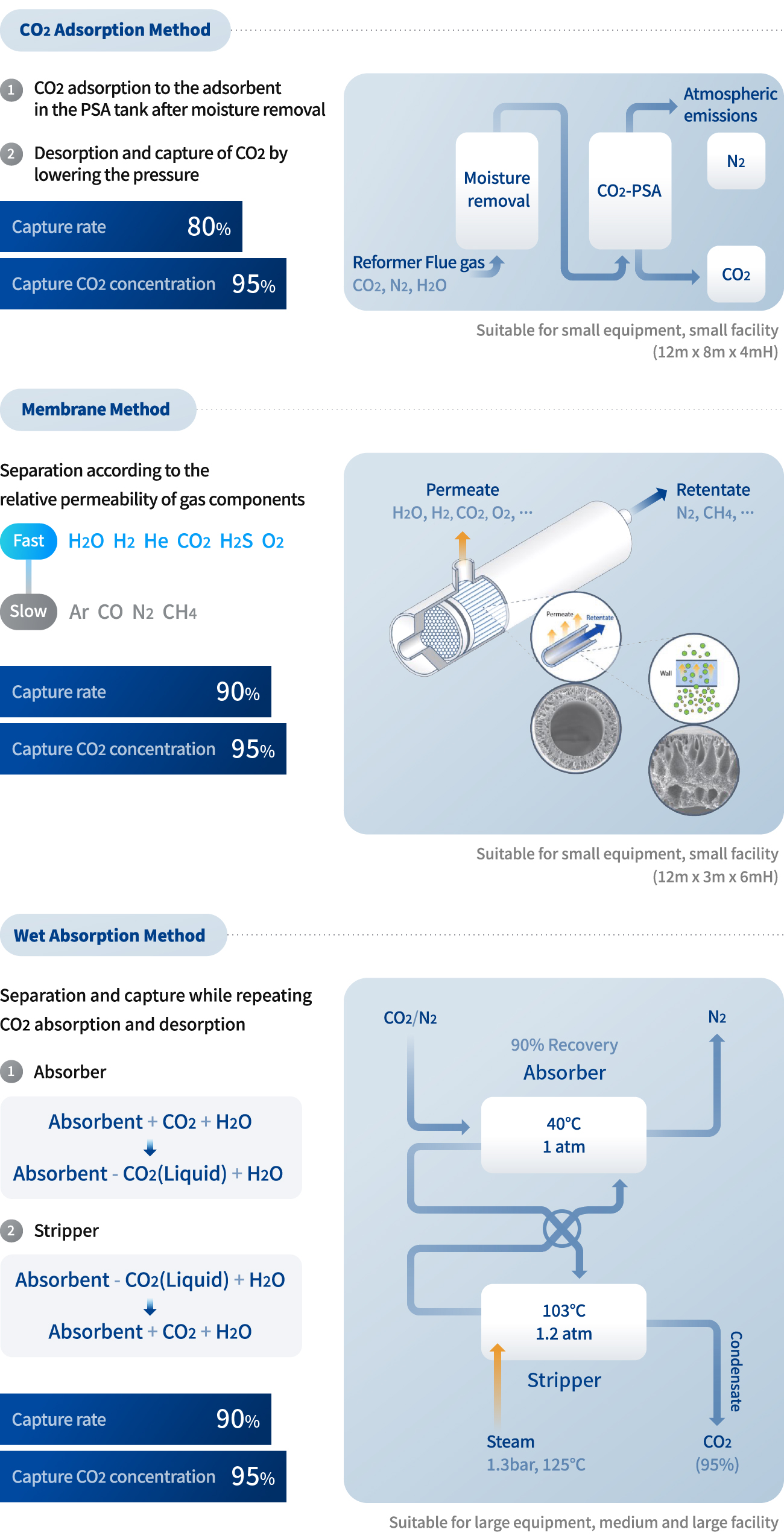

CCU, Carbon Capture Unit

The most efficient and economical hydrogen production is the method of utilizing natural gas as a raw material. However, natural gas has a carbonized (C)-based component that emits carbon dioxide (CO2) after hydrogen production. In addition, the larger the hydrogen production facility, the greater the amount of CO2 emitted. In other words, there is a contradiction in which CO2 is emitted to create an eco-friendly hydrogen energy. To solve this problem, Hyundai Rotem is working to reduce carbon emissions through carbon capture devices and to approach the goal of ‘ultimate eco-friendly energy production.

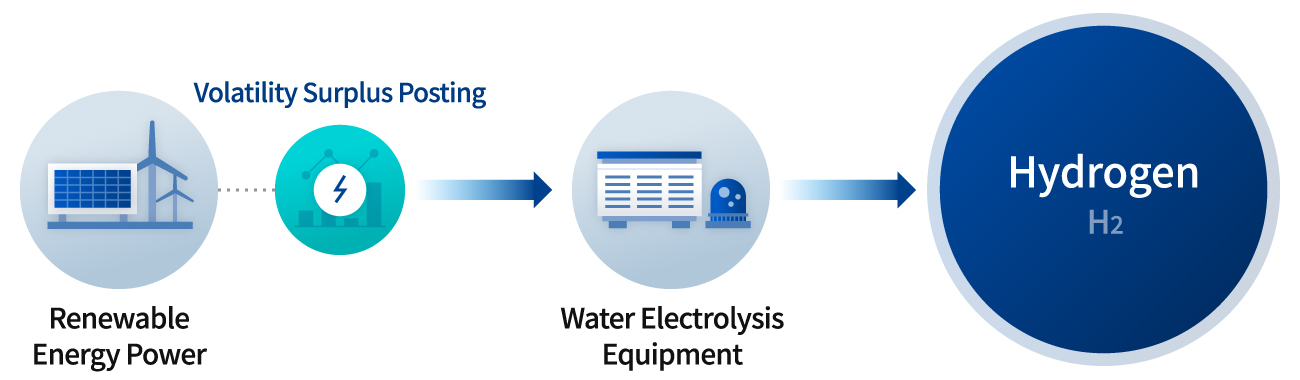

Electrolysis

Electrolysis is a production method that applies electrical energy to water (H2O) to separate oxygen and obtain hydrogen (H2). It is the ultimate eco-friendly hydrogen production since it does not emit carbon dioxide, other greenhouse gases or air pollutants in the production process. Currently, among various types of electrolysis production systems, alkaline electrolysis systems and solid polymer electrolysis systems are commercialized. Alkaline electrolysis system is a technology that is more than 100 years old and has reached a technologically mature stage compared to solid polymer electrolysis system, but it is difficult to apply to renewable energy facilities (green hydrogen production). This is because renewable energy facilities are highly volatile in power production due to their nature’s power utilization. Accordingly, Hyundai Rotem is developing a polymer electrolyte electrolysis system that can quickly respond to renewable energy facilities with severe load fluctuations and can produce high-pressure hydrogen without a separate compressor.