At the “RailLog Korea 2023,” Hyundai Rotem made significant announcements regarding the development of high-speed trains and their vision for achieving carbon neutrality through hydrogen mobility. Let’s look at the highlights of the event, involving the value of Hyundai Rotem’s commitment to the future of the railroad industry and its dedication to sustainable growth, which garnered significant attention from both Korean and international experts and visitors in the industry.

The host, Lee Won-sang, head of Hyundai Rotem’s Rail Solution R&D Center, commenced the event with a keynote speech. The global paradigm shift towards greenhouse gas reduction, low carbon, and green energy following the Paris Climate Agreement in 2015. Against this backdrop, numerous advantages of railways, such as safety, punctuality, affordability, convenience and eco-friendliness receive higher attention than before. He emphasized that railways are the optimum means of mass mobility for fast, safe, affordable, convenient and environmentally friendly transportation.

Celebrating its 20th anniversary of high-speed rail, Hyundai Rotem solidifies its position as a leader in high-speed vehicles

Gong Myung-sang, team leader of the Rail Solution R&D Center at Hyundai Rotem, presented the Rotem’s development history of high-speed trains in line with the global rail industry trend focused on high-speed rail. He highlighted the core technology of the GTX electric train and shared Hyundai Rotem’s vision for various research activities, including overseas expansion based on their accumulated technology.

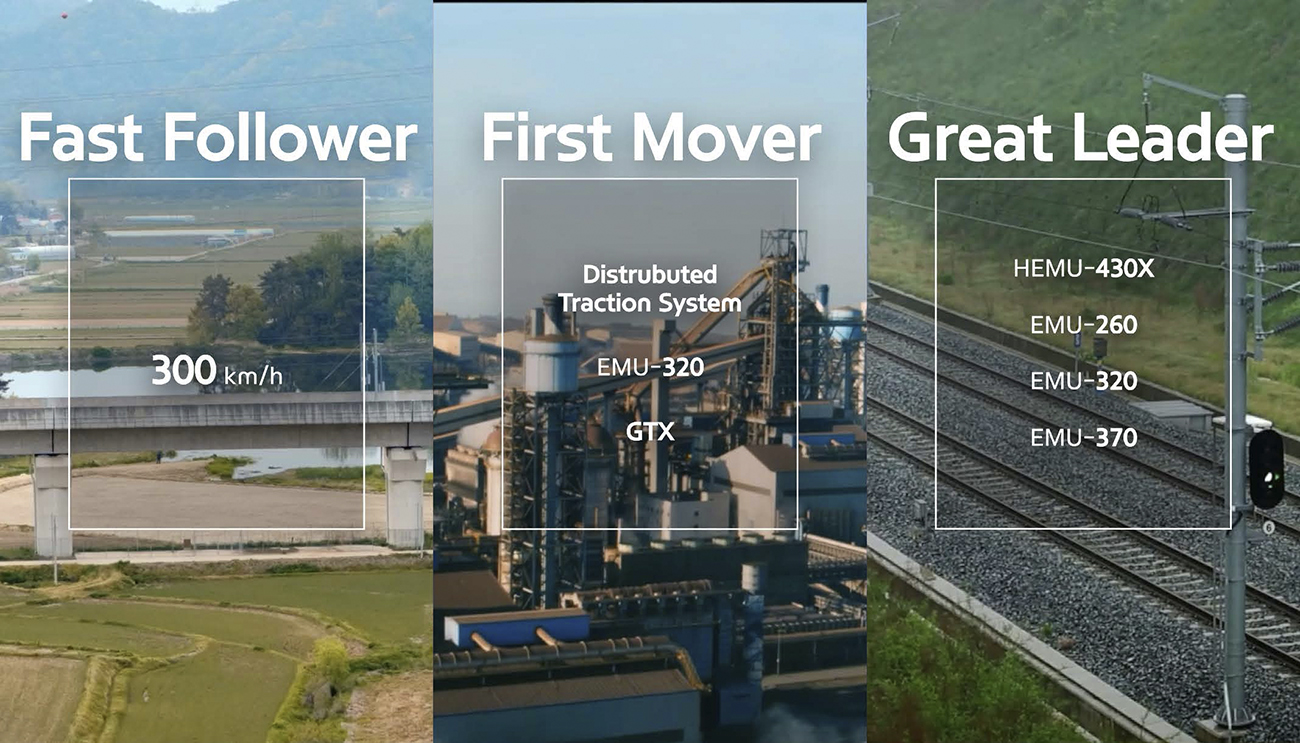

Korea’s high-speed railway, celebrating its 20th anniversary since its opening in 2004, has become a leader in high-speed trains. By introducing the KTX high-speed train from France in 1989 and developing the Korean G7 high-speed train with a maximum speed of 350 km/h, Korea achieved localization of core components and elemental technologies. With the successful commercialization of “KTX Sancheon,” developed solely with domestic technology, Korea together with Hyundai Rotem became the fourth country in the world, after Japan, France and Germany, to independently design and manufacture high-speed trains with speeds exceeding 300 km/h.

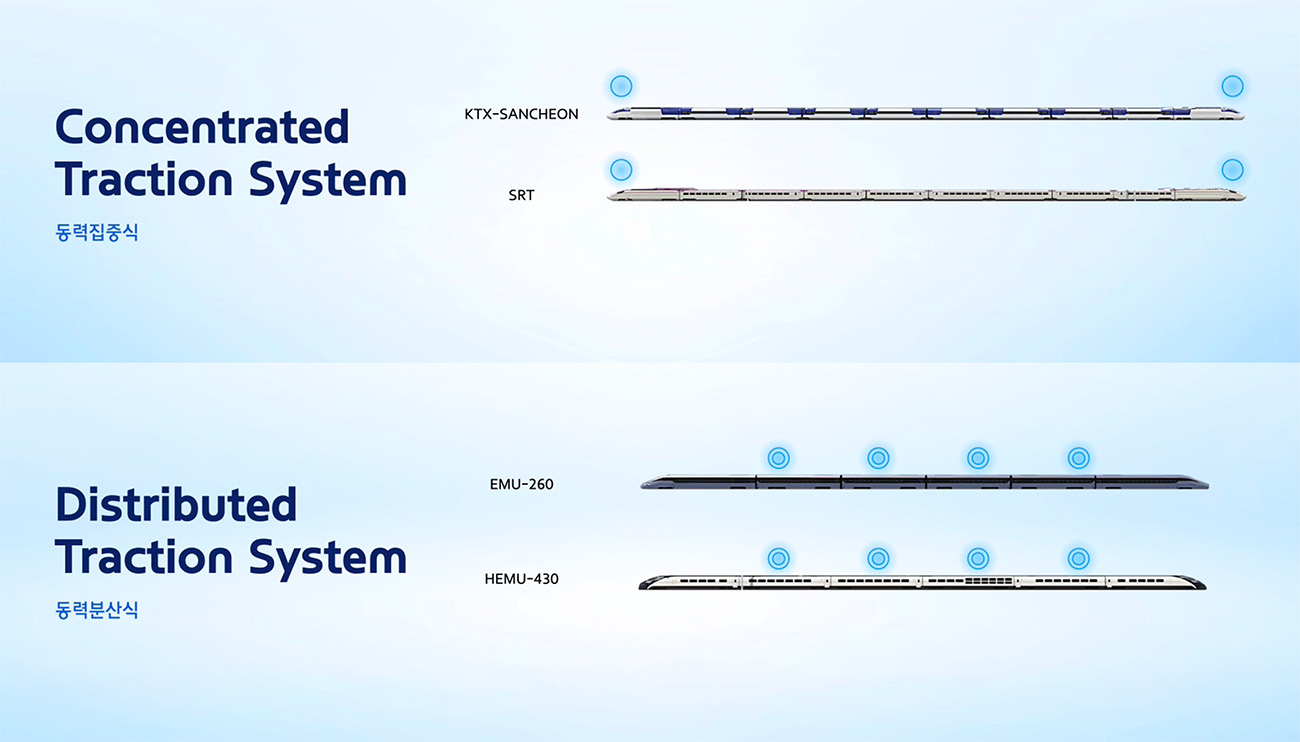

To actively respond to various demands in Korea and overseas, Hyundai Rotem has secured technology exceeding 420km/h through “HEMU-430X”, known as Rotem’s distributed traction system high-speed trains development project. In addition, Hyundai Rotem successfully developed and mass-produced “EMU-260 (KTX – EUM),” which was deployed on the Gangneung Line, Jungang Line, and Jungbu Inland Line starting in January last year. The ongoing development of distributed traction system high-speed trains, such as the “EMU-320”, with an increased target speed of 320 km/h, is expected to be operational on the Honam High-Speed Line in the near future.

Compared to the concentrated traction system with locomotives at both ends, the distributed traction system, with distributed power sources in the middle and lower parts of the trains, offers enhanced energy efficiency and superior acceleration controls. These features are well-suited for Korean railways that require frequent acceleration and deceleration to minimize travel time between stations. Furthermore, the global high-speed train market has a preference for the distributed traction system due to its operational efficiency, indicating positive prospects for overseas exports.

GTX connects Seoul and the capital area with world class railway technologies.

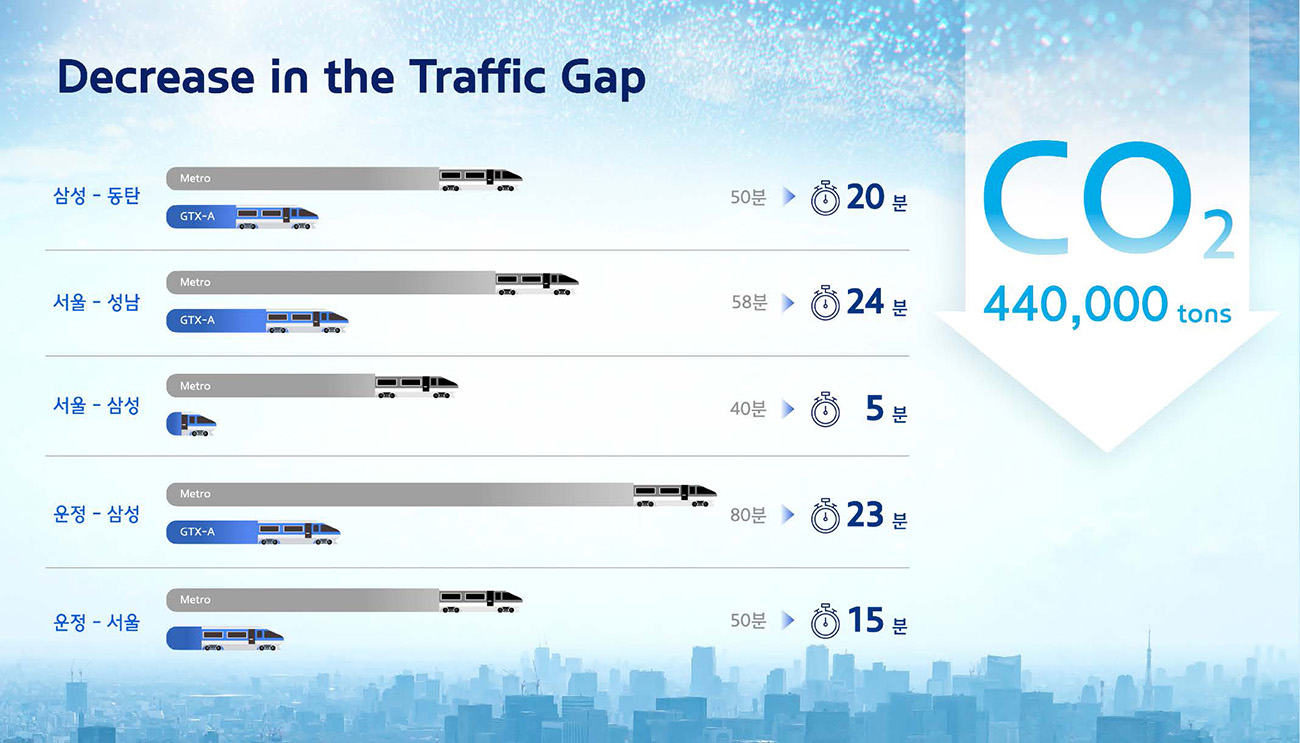

Hyundai Rotem also explained the Metropolitan Express Railroad, “GTX.” GTX is designed with tracks located at a depth of 40 meters or deeper underground, enabling a straighter route and achieving a maximum operating speed of 180 km/h. Its scheduled speed is twice faster than existing subways. GTX-A line, connecting Unjeong and Dongtan, is expected to significantly reduce travel time between Seoul and the capital region to just about 30 minutes. The GTX’s impact includes a reduction in traffic congestion in the outskirts of the metropolitan area and a projected decrease in carbon dioxide emissions by approximately 440,000 tons per year.

The interior is designed to provide comfortable riding even during high-speed driving and operations in tunnels. It incorporates an air purification system to ensure a pleasant interior environment. To reduce air noise and improve airtightness, the train utilizes a 1.6m-long “noise reduction single-door plug-in door” and windows for high-speed vehicles to effectively mitigate the external impact and reduce noise inside. Passenger comfort is further enhanced by widened seats to 480mm from 450mm and applying a seat-separable structure, significantly improving convenience and privacy. Also, the train was fitted with carpets certified with eco-friendly certification, as it created a cozy yet luxurious interior atmosphere.

Starting with the GTX-A line, which is planned to open next year, Hyundai Rotem aims to build world-class electric vehicles and provide services on the upcoming B, C, and D lines, leveraging their expertise in high-speed train development.

The Present and Future of the Hydrogen Mobility, the Ultimate Alternative to Carbon Neutrality

The next presenter, Jung Hoon, Head of the Core Technology Development Group took the stage to talk about hydrogen mobility as one of Hyundai Rotem’s core businesses to demonstrate Hyundai Rotem’s leadership in green railroads and their commitment to the future.

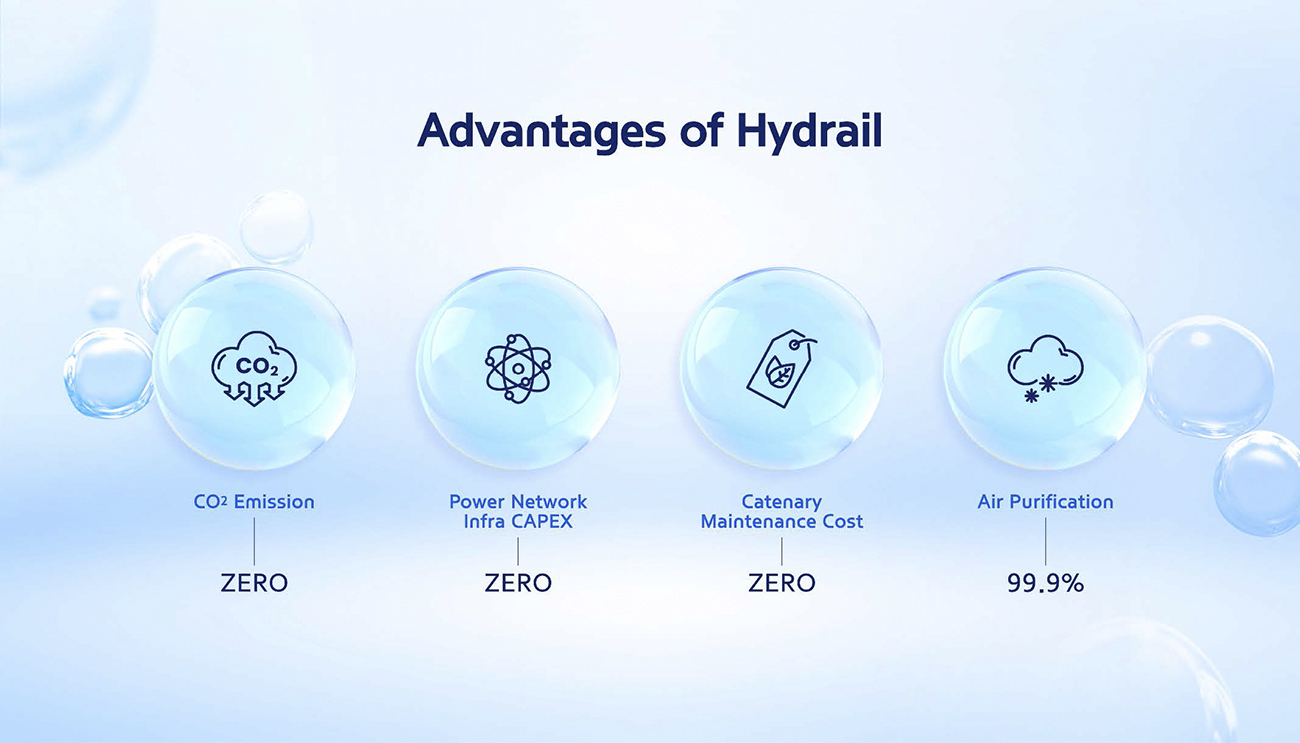

Hydrogen is the most eco-friendly energy source. As hydrogen emits zero pollutants except water, it does not generate any environmental pollution during its operating process. Also, due to its higher energy density compared to conventional batteries, it is ideal for large-capacity energy supply. This characteristic makes hydrogen the ideal solution for the railroad sector, which requires long-distance, high-volume transportation with an independent energy source. Additionally, hydrogen trains don’t require dedicated power infrastructure such as rails and substations, reducing construction and maintenance costs associated with power facilities.

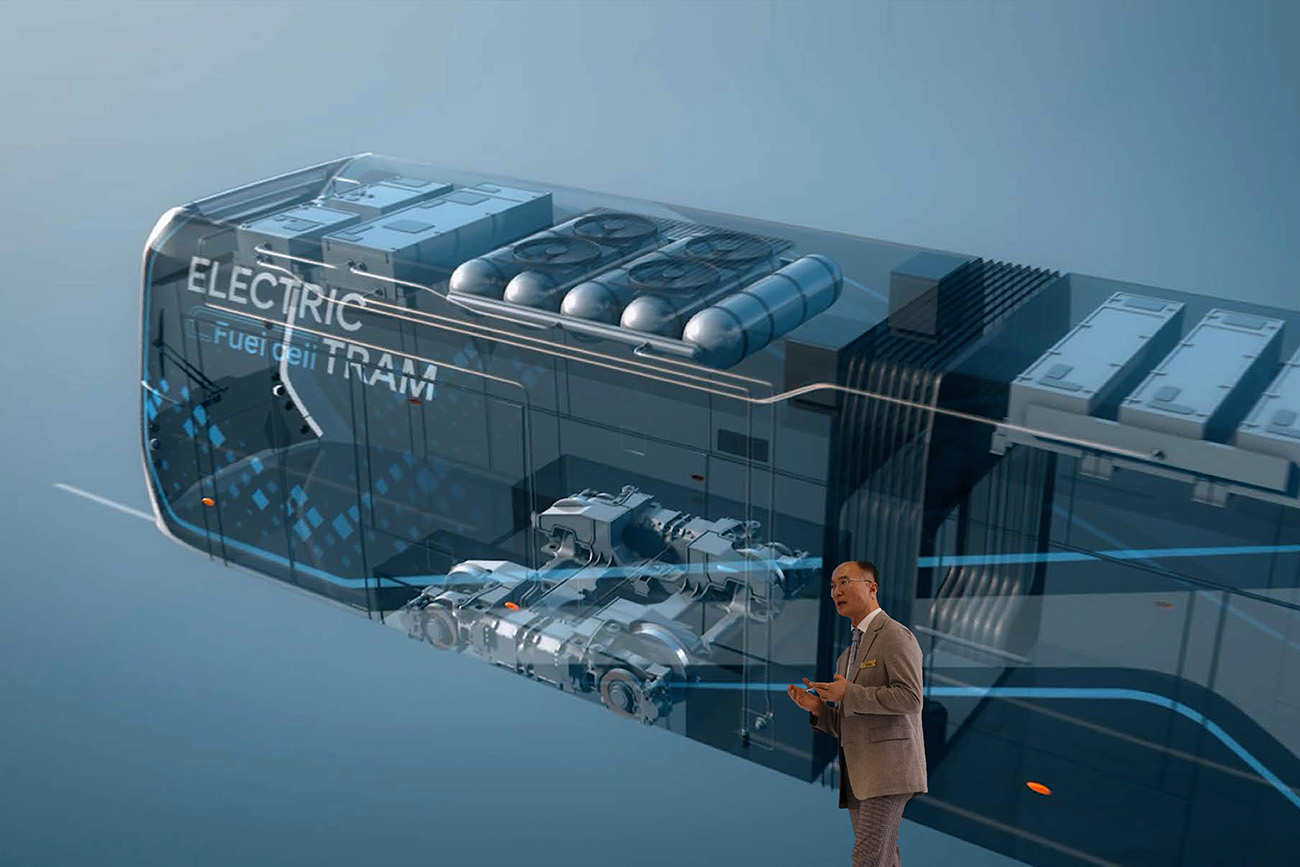

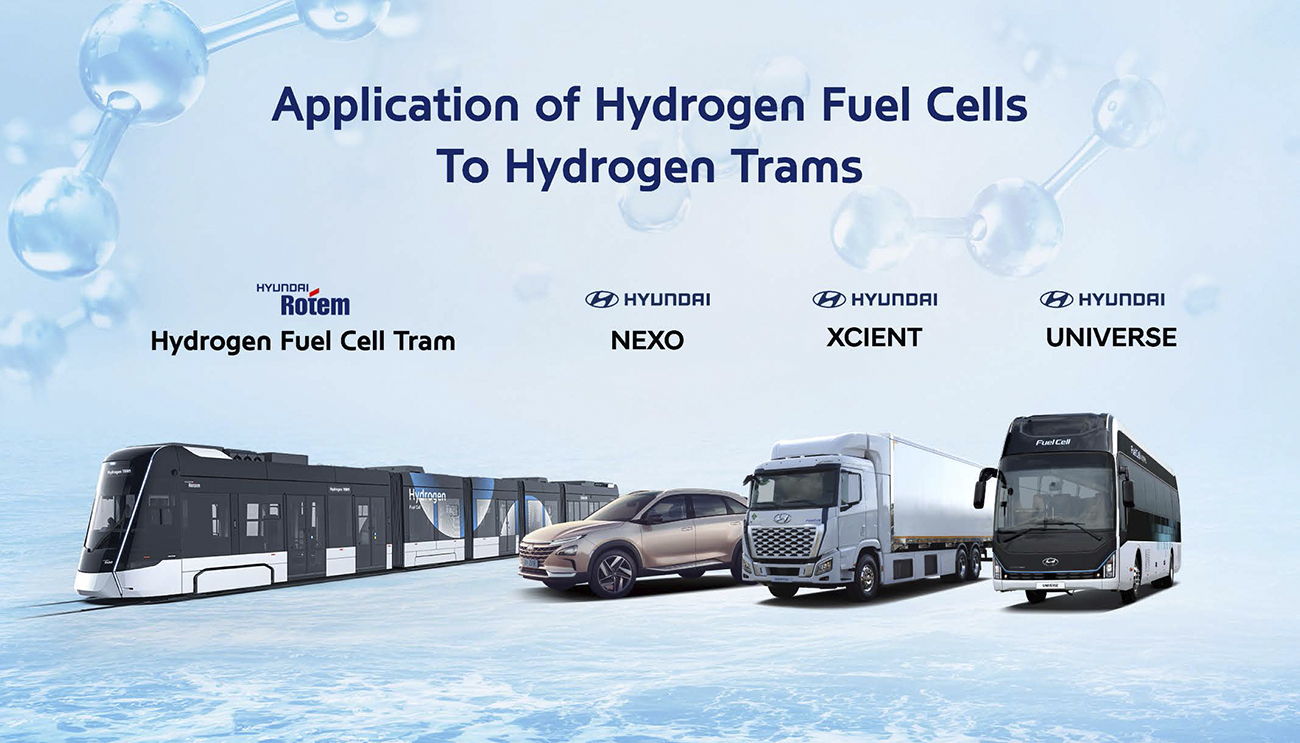

Hyundai Rotem has successfully introduced a hybrid battery and hydrogen fuel cell using Hyundai Motor’s expertise, and developed a hydrogen fuel cell package system. Hyundai Rotem validated the performance of the hydrogen fuel cell system by incorporating it on a prototype tram and conducting driving tests in March 2021. Subsequently, in July 2021, Hyundai Rotem commenced its mass-production.

This is a demonstration project in 2021 run by the Ministry of Trade, Industry and Energy and final development and tests are expected by the year’s end. With the participation of Ulsan Metropolitan City, the tram will enter actual operations in Ulsan in the second half of 2023.

The foundation of the hydrogen fuel cell tram lies in its hydrogen fuel cell. This system, mounted on the tram’s roof, is based on the commercially successful and verified hydrogen vehicles of Hyundai Motors, such as NEXO, buses and trucks to secure performance and safety.

Featuring four 95 kW hydrogen fuel cells, the hydrogen tram has two independent power sources by placing two cells and a high-powered rechargeable battery which is located in the middle module of each lead car. During the initial operations, power generated by the hydrogen fuel cells is supplied. When accelerating, any power deficit is supplemented by power from the batteries. When braking, regenerative energy is stored in the battery via the traction motor, enhancing the energy recycling rate. This operating principle enables the train to travel up to 150 kilometers on a single full-charge.

To build a hydrogen mobility ecosystem, hydrogen production technology is also important. The company has secured the technology to extract high-purity hydrogen from natural gas and biogas, while also striving to develop various in-house technologies to advance the hydrogen business. Additionally, by-product hydrogen, which was previously not recyclable, can now contribute to the expansion of the domestic hydrogen supply as an energy source in a more eco-friendly manner.

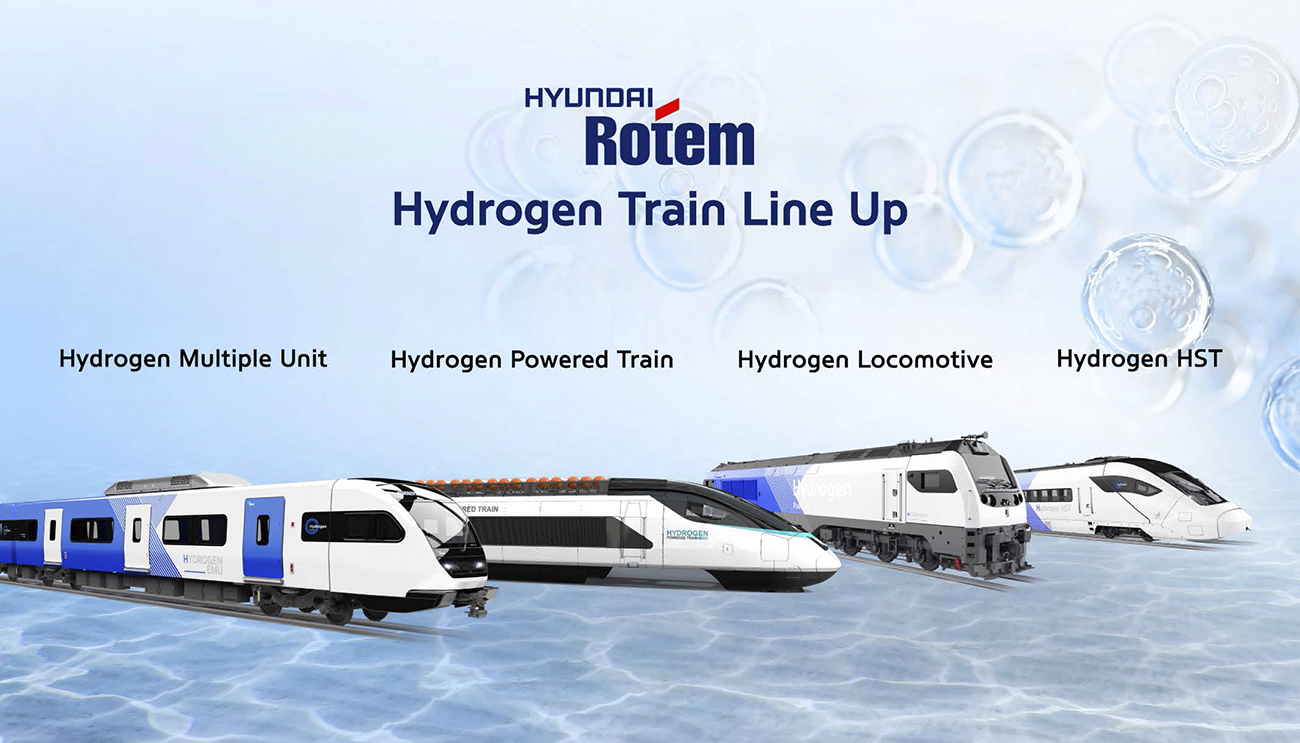

Following the hydrogen tram, Hyundai Rotem is actively engaged in the development of hydrogen trains. Focusing on the world’s first liquefied hydrogen-based core technology, the company will commence the development of hydrogen-powered vehicles with increased power output and hydrogen payload in 2024, enabling long-distance operations. Also, Hyundai Rotem unveiled its roadmap for developing a hydrogen-powered train model with an increased speed of up to 180km/h by 2027 and demonstrating Hyundai Rotem’s commitment to pushing the boundaries of performance and efficiency in hydrogen-powered transportation by 2030.

The RailLog Korea 2023 showcased Hyundai Rotem’s accomplishments as a “Fast Follower,” “First Mover” and “Great Leader” in the railroad industry, including high-speed trains, while presenting a clear vision for leading the future era of eco-friendly mobility. This event reaffirmed Hyundai Rotem’s competitiveness in the global railroad market, particularly in the development of eco-friendly hydrogen mobility.