Global warming caused by thoughtless green-house gas emissions has worsened beyond the self-purification capacity, putting mankind in the face of national disasters. As eco-friendly energies are needed to reduce green-house gas emissions regardless of sectors, the entire world is focusing on hydrogen.

Transition of energy paradigm

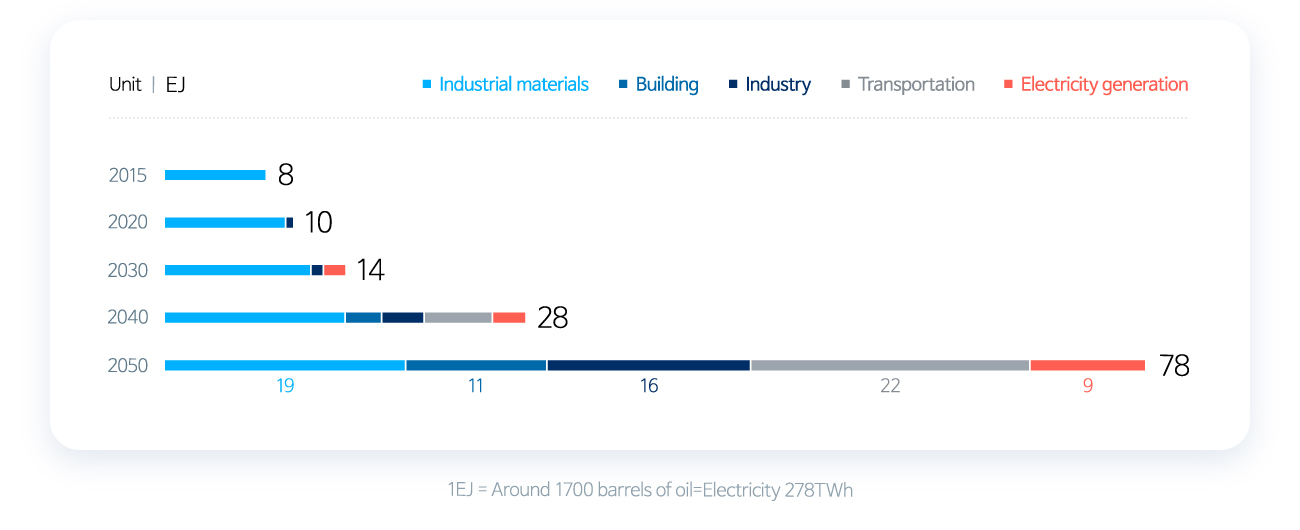

The world is rapidly shifting towards hydrogen society where electric energy is produced from hydrogen. Major advanced countries are investing a considerable amount of time and resources into the entire process of hydrogen value chain from production, transportation, storage and utilization to improve the technical and commercial perfection and lead the hydrogen economy. According to Hydrogen Scaling Up, 2017 published by global consulting company Mckinsey, the global annual demand for hydrogen is forecast to reach 78EJ (equivalent to around 13.26 billion barrels of oil when converted) in 2050.

Currently, hydrogen is mostly used for industrial purposes. However, it is expected to extend to various fields, as well as electricity generation and transportation in future. In terms of transportation, hydrogen has a very high energy density, so it will be highly competitive among the long-distance and heavy transports such as truck, bus, commercial vehicle, airplane and railway. For example, in case of a long-distance truck that runs over 800km, installing a hydrogen fuel cell is lighter by 2.5 times than installing an electric battery for traveling the same distance, which means a higher fuel efficiency and heavier load.

Industries consume enormous thermal energies. For this, numerous fossil fuels are being used, emitting green-house gases considerably. Amid the global efforts to reduce green-house gas emissions, hydrogen, which is a clean energy, is increasingly being introduced in industries. The introduction of hydrogen energy is expected to surge as fuel cell systems installed in buildings allow simultaneous supply of heat and electricity for heating, not to mention reduce green-house gas emissions.

Hydrogen production facility, the core of hydrogen infrastructure

As the utilization of hydrogen is increasing across the industries, the production volume of hydrogen is becoming a key to leading the hydrogen economy. Currently, Korea is standing out in utilizing hydrogen energy, but the infrastructure to produce and supply hydrogen energy is somewhat lacking. If the situation continues, we may have to rely on hydrogen import, as we did in the past with fossil fuels, for which we are highly relying on imports.

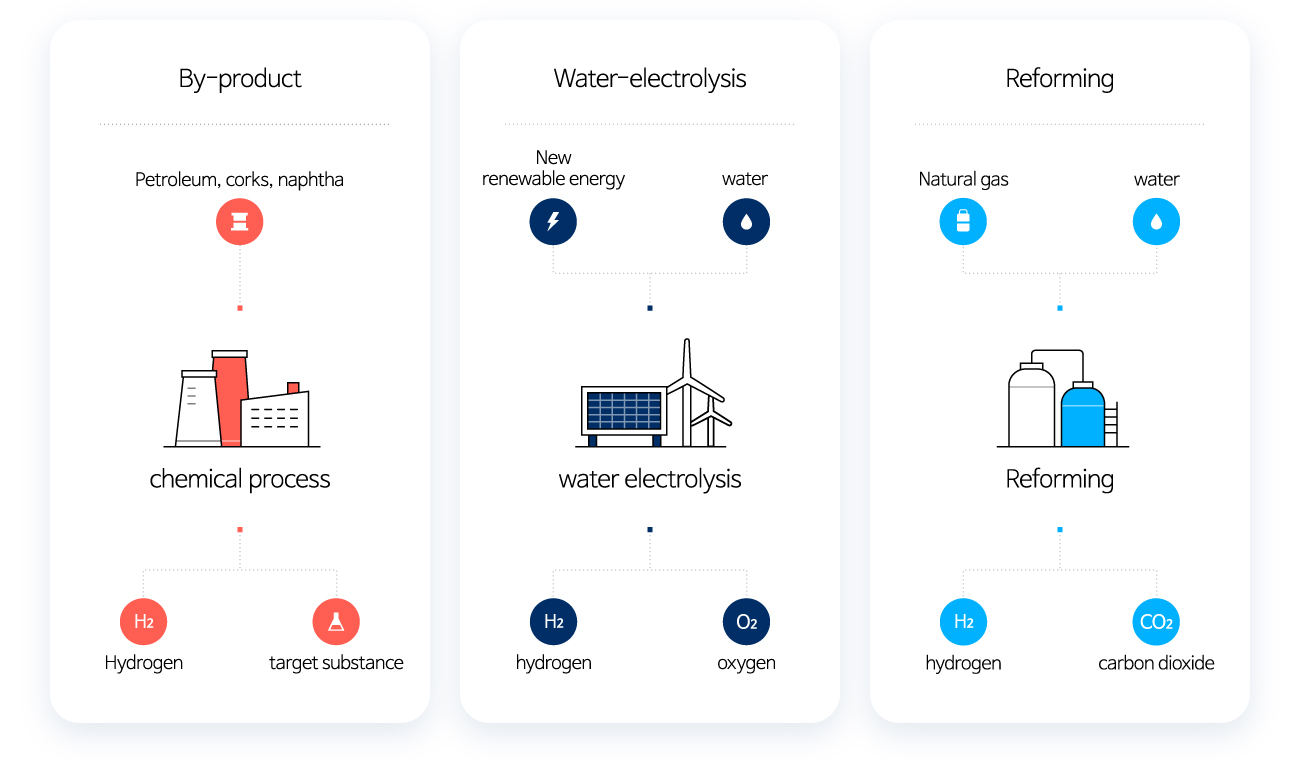

Hydrogen production is largely divided into three types; by-product, water electrolysis, reforming. By-product hydrogen is hydrogen generated as a by-product in the petrochemical process. The petrochemical industry is well developed in Korea, so the production volume of by-product hydrogen is high. Although, it is hard to consider it as an infrastructure for hydrogen production as it is produced as a by-product.

Water electrolysis is to produce hydrogen by dissolving water using electricity obtained from new renewable energies such as solar power and wind power. It is regarded as the most eco-friendly hydrogen production method as it produces pure oxygen only, besides hydrogen. However, it requires more time and cost in building the production infrastructure than other hydrogen production methods, so it should be pursued ultimately.

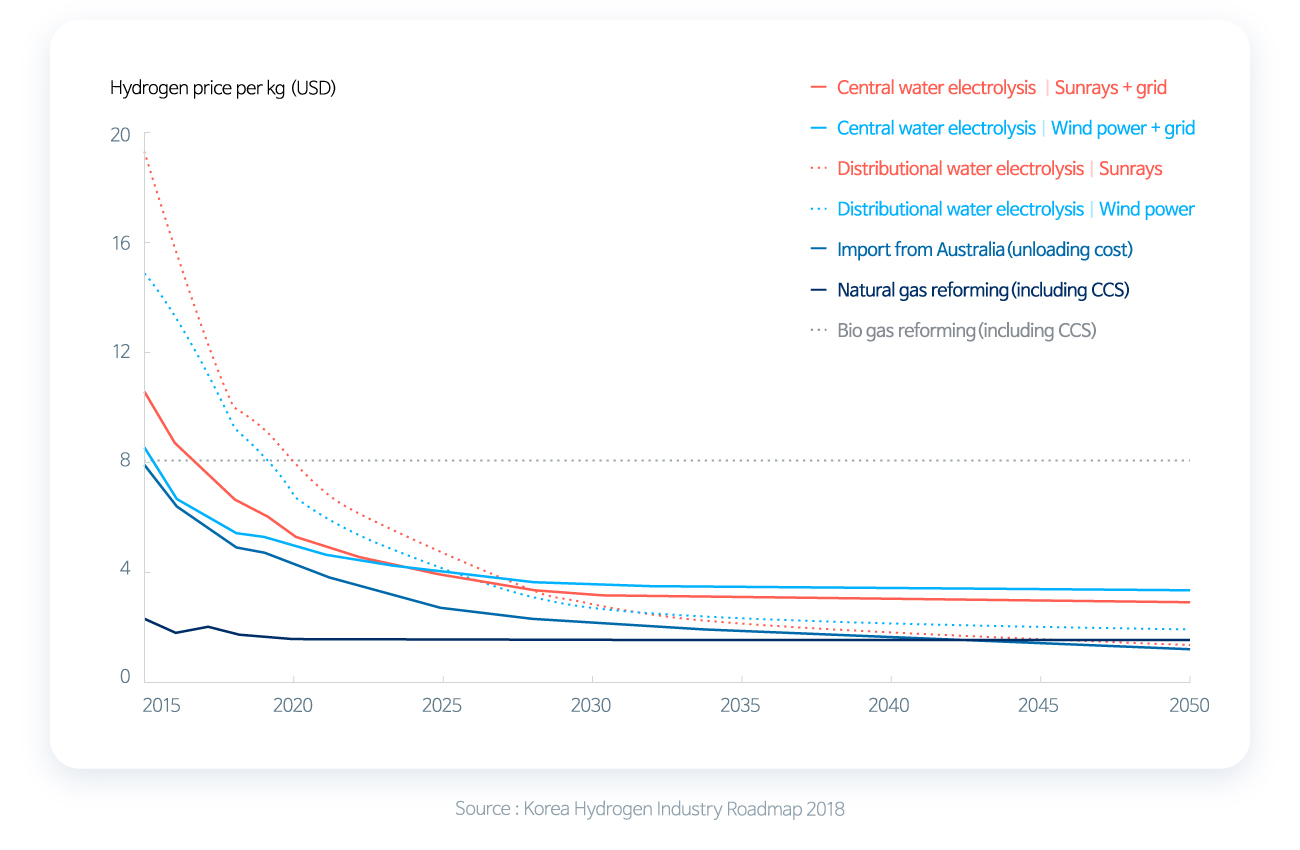

Reforming is to produce pure hydrogen by causing a chemical reaction between natural gases and steam at a high temperature and high pressure. It is universally used across the world, making up the half of the global hydrogen production. It can produce hydrogen sufficiently as long as natural gases are supplied sufficiently. It also has a strength in terms of production cost, so it is appropriate as an initial infrastructure to enter hydrogen society. Namely, expanding the reforming facilities is very important in the current circumstance.

Hyundai Rotem’s hydrogen reformer

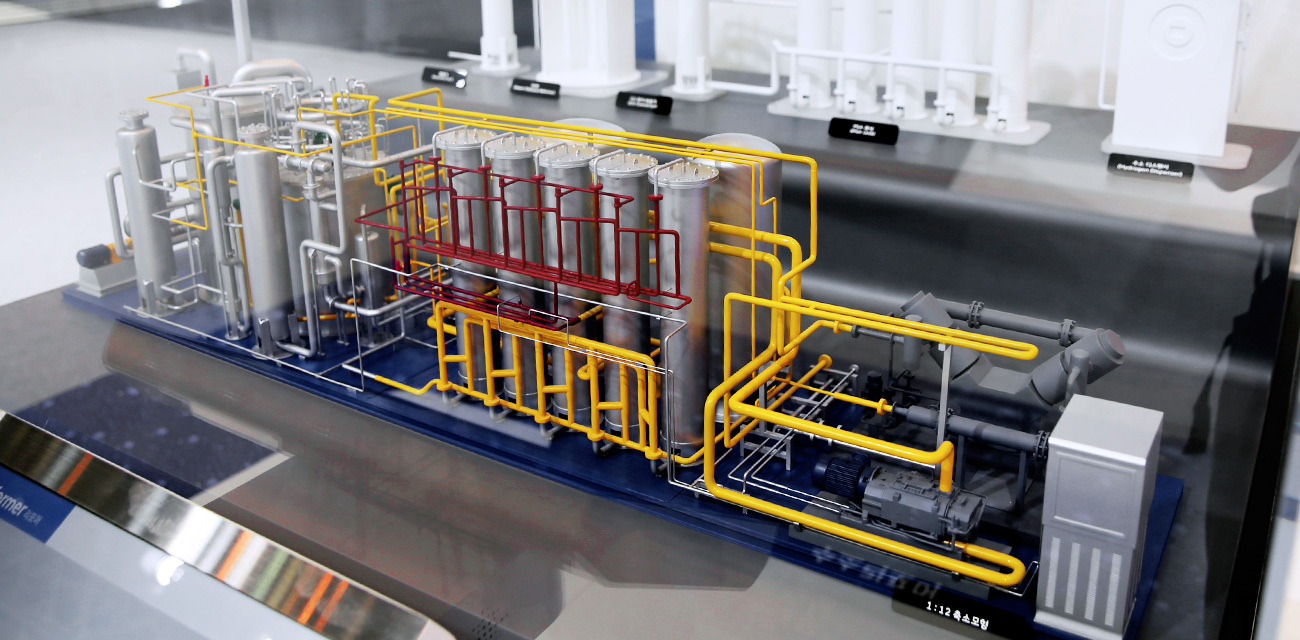

Last year, Hyundai Rotem entered the hydrogen infrastructure industry to build a hydrogen infrastructure that will accelerate the shift into hydrogen society. Hyundai Rotem’s hydrogen infrastructure business is to provide a total solution for the entire process of hydrogen station establishment from design to purchase and construction. The major core field is hydrogen reformer that extract hydrogen through reforming. Hyundai Rotem built a hydrogen reformer factory, H2 Facility Assembly Center inside its Uiwang R&D Center in an area of 2,000m2 (around 600 square meters) after obtaining the source technology for hydrogen extractors. The assembly center can manufacture 20 hydrogen reformers every year. The 20 hydrogen reformers can produce 4,700 tons of hydrogen annually, which can fill 850,000 hydrogen electric cars (of NEXO) fully.

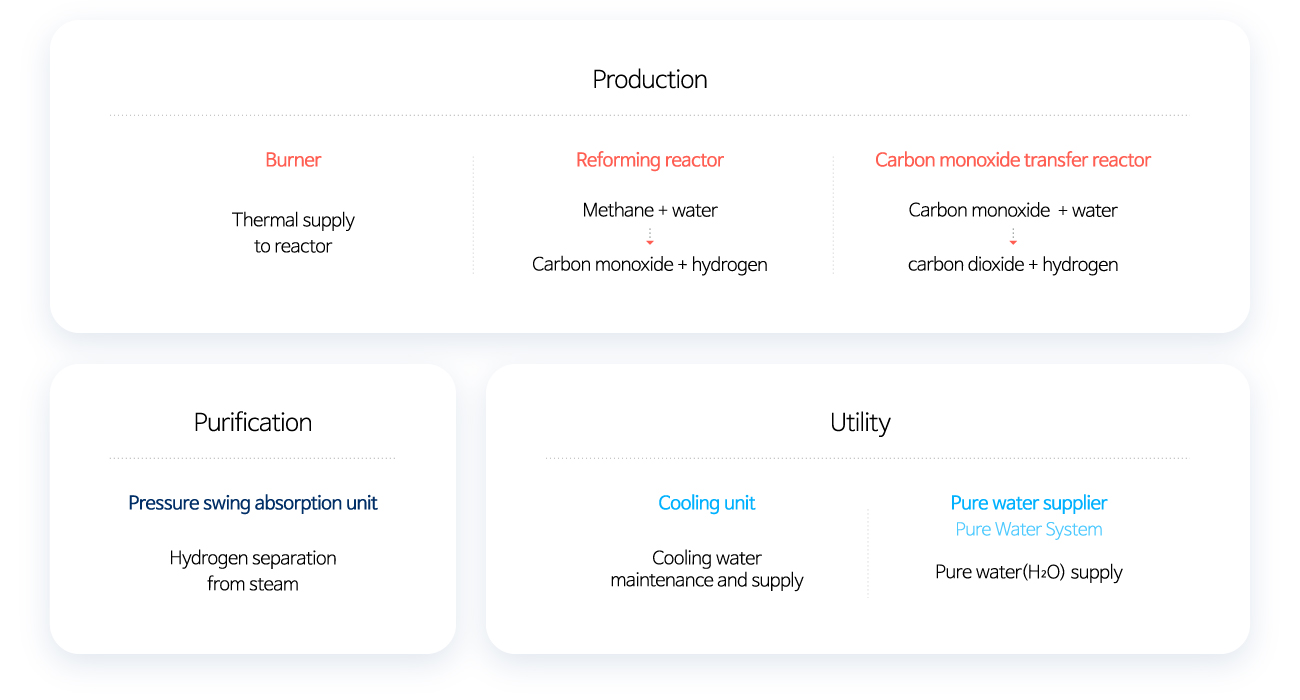

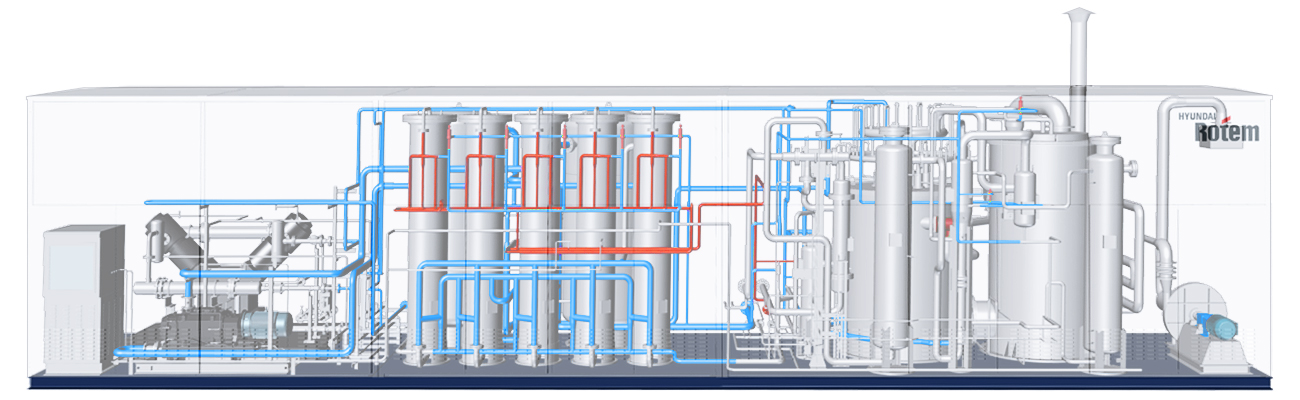

Hyundai Rotem’s hydrogen reformer removes sulfur from a natural gas compressed by the gas compressor in the sulfur removing tower, mixes it with pure water and feeds it to the reforming reactor. The natural gas and pure water are reformed into carbon monoxide and hydrogen by the reforming reactor. The remaining carbon monoxide and pure water in the reforming reactor are ultimately reformed into carbon dioxide and hydrogen through the carbon monoxide transfer reactor. Subsequently, impurities are eliminated by the pressure swing absorption unit (PSA Unit) to produce a high-purity hydrogen. The produced hydrogen is carried through tube trailers or to hydrogen stations for use in needed areas.

As above, Hyundai Rotem’s hydrogen reformer successfully produced domestically can supply hydrogen to the hydrogen market. However, the major advantage is that when a hydrogen reformer connector is installed on the existing supply network, hydrogen buyers can produce hydrogen directly and use immediately. In Korea, city gas or bio gas has already been used in many cities, and Hyundai Rotem’s hydrogen reformer is slightly larger than 40FT (actual size 15.2 x 3 x 3.6m). Thus, they can be installed in needed areas immediately and reduce the hydrogen distribution cost. Hyundai Rotem is planning to cut down the production cost by increasing the domestic production of hydrogen reformer components to 80% so as to enhance the price competitiveness of hydrogen production continuously.

Meanwhile, Hyundai Rotem is attempting to make large hydrogen reformer, following the domestic production of hydrogen reformers. The hydrogen reformers in the current production have a capacity of 640kgs a day. Hyundai Rotem is developing mid to large-sized hydrogen reformers with a more capacity. As mid to large-sized hydrogen reformers cost less in production than small-sized extractors, it is expected to bring a positive effect of hydrogen price decrease.

Hyundai Rotem’s efforts for establishment of hydrogen infrastructure

The production of hydrogen reformers is in full swing in Hyundai Rotem’s hydrogen reformers factory, H2 Facility Assembly Center located in Uiwang Research Center. Currently, hydrogen reformers for domestic supply such as Chungju and Samcheok are off the production line, ready for delivery. Besides producing the hydrogen reformers, Hyundai Rotem is expanding its business territory across the hydrogen infrastructure industry such as hydrogen charger and hydrogen release center. Hyundai Rotem’s hydrogen charger infrastructure business is expected to make synergy with hydrogen electric trams that are currently being developed by Hyundai Rotem and contributes to supplying hydrogen energy in all areas of our lives.

The world is advancing towards a hydrogen society rapidly. Amid the global transition of energy paradigm to hydrogen energy, building a hydrogen infrastructure that has safety, convenience and feasibility and obtaining relevant technologies constitute a global competitiveness in the future energy industries. Hyundai Rotem is rapidly succeeding in domestic production of hydrogen infrastructure-related facilities by collaborating with various companies in Korea. Ultimately, it aims to achieve global competitiveness for the domestic hydrogen industry by reducing production costs and accelerating expansion of hydrogen infrastructure across the country.