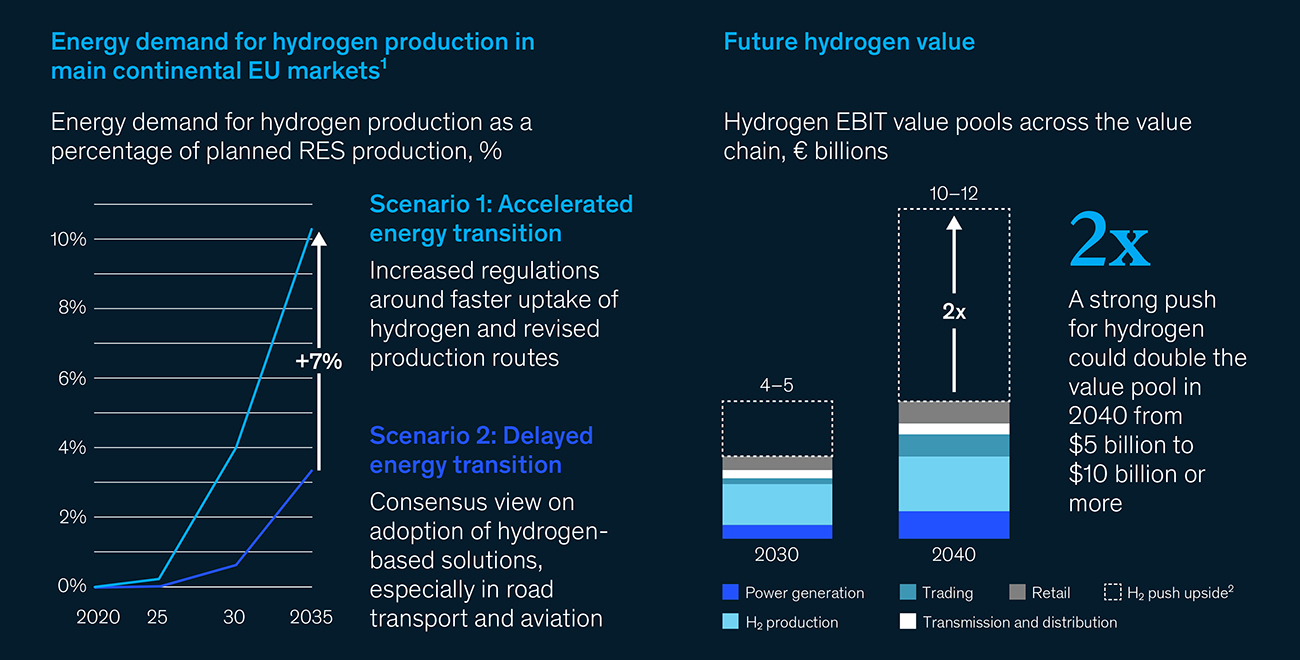

Hydrogen is an infinite substance that accounts for more than 90% of the molecules in the universe. In addition, it is suitable as an eco-friendly energy for a sustainable future since it emits only pure water in the process of creating energy by combining it with oxygen. According to the global consulting firm McKinsey’s report on the potential of hydrogen, 2022, hydrogen is rapidly emerging as a key solution to achieve global climate goals. In the future, decarbonized power grids will be activated and hydrogen will be able to replace fossil fuels in all industries. The main drivers of growth throughout the hydrogen value chain are green hydrogen power generation and hydrogen production itself. It is expected to account for most of the value chain within the next 20 years.

Trains meet hydrogen

This prospect has already become a reality, and hydrogen-powered vehicles can now be easily seen on the road. Not only automobiles, but also drones, ships, and trains powered by hydrogen are rapidly being commercialized. As such, hydrogen energy is being used as an energy source for various transportation means. In particular, its usability in the railroad field is drawing great attention. This is because hydrogen energy is not only eco-friendly, but also superior to other energies in terms of installation, usage, and energy efficiency.

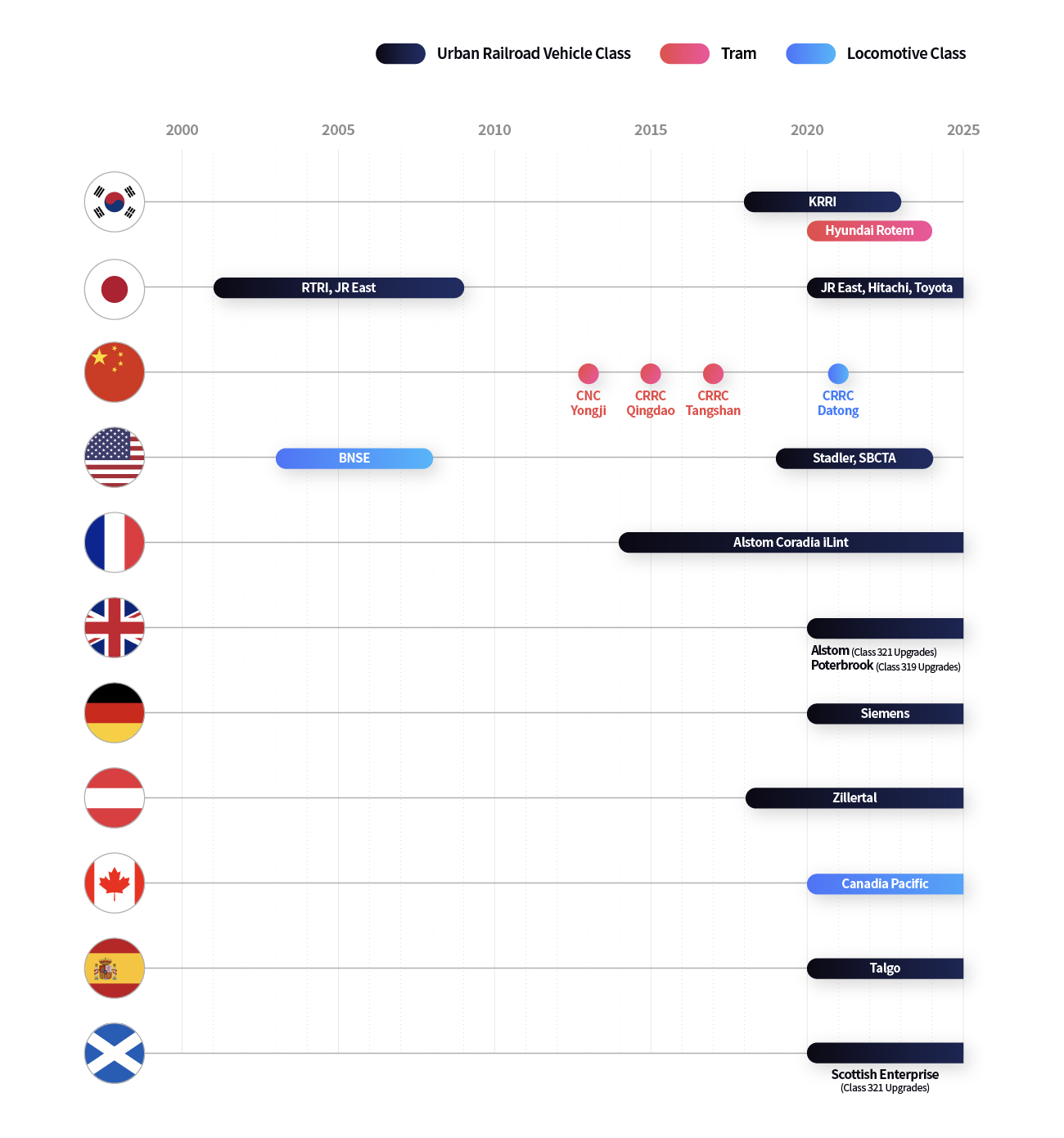

Therefore, major railroad companies around the world are putting much effort into the development and mass production of trains using hydrogen energy. Germany started operating the world’s first hydrogen-powered train ‘Coradia iLint’ in 2018. This train was developed by French railroad company Alstom with funding from the German government. It is a method of mounting a fuel cell that produces electricity using hydrogen as a fuel, storing the energy produced by chemical reaction in a lithium-ion battery located at the bottom of the train, and then using it as a power source when necessary. The maximum speed is 140 km/h and the operating distance is 600 to 800 km on a single hydrogen charge. Germany aims to replace all diesel trains nationwide with hydrogen trains by 2040.

Siemens developed the Mireo Plus H, a hydrogen-electric vehicle, and it will test it in Augsburg – Füssen section in 2023, and it will start operating in Germany’s “Bayern Regiobahn” in 2024. It is operated by connecting the battery at the bottom of the vehicle and the hydrogen fuel tank at the top, and can operate up to 800 km. If a total of 1,300 diesel trains operating in Germany are replaced with Mireo Plus H, 330 tons of carbon dioxide per train can be reduced annually.

France also succeeded in test operation of Alstom’s hydrogen train. It plans to commercialize hydrogen trains by 2025, and then convert all diesel locomotives into hydrogen trains. The UK developed the first hydrogen train in 2019 and started its first test operation the following year. In addition, not only major European countries, but also the United States and Japan are interested in hydrogen trains and they are starting to develop technology for practical use.

Hydrogen trains are also being developed in Korea. Hyundai Rotem has secured the necessary technology of hydrogen electric trams through prior research since January 2019 and unveiled the hydrogen tram concept car to the public in April 2021. Through the development of a hydrogen tram concept car (platform vehicle) consisting of 3 modules in 1 formation, the applicability of the hydrogen tram to the hydrogen system in the automobile field was confirmed. Since July 2021, four leading organizations, including Hyundai Rotem, Korea Automotive Technology Institute, Korea Railroad Research Institute, and Ulsan City (Ulsan TP), are conducting a “Demonstration Project of Hydrogen Electric Trams” in the form of a consortium organized by the Ministry of Trade, Industry and Energy, involving a total of 22 local governments, non-profit institutions and companies. This vehicle is being developed with the goal of a maximum speed of 70 km/h and a operating distance of up to 150 km on a single hydrogen charge.

In addition, Hyundai Rotem is developing core technology for a liquefied hydrogen-based hydrogen locomotive, which has evolved one step from the hydrogen train using gaseous hydrogen introduced by other global railroad companies. Liquefied hydrogen literally means that hydrogen is liquefied by cooling it to a low temperature (-253℃). Since it is 800 times smaller in volume than gaseous hydrogen, storage safety and economic efficiency are very high. This technology, which Hyundai Rotem is researching with the Korea Railroad Research Institute, is expected to accelerate its entry into the hydrogen train era. This is because liquefied hydrogen, which has a storage density twice as high as that of a gas, is used, the operating distance on a single charge is increased to 1,000 km, which is about 1.6 times longer than the previously launched European gas hydrogen train, and the fuel charging time is reduced by about 20%.

The energy source of hydrogen train, The safety of hydrogen

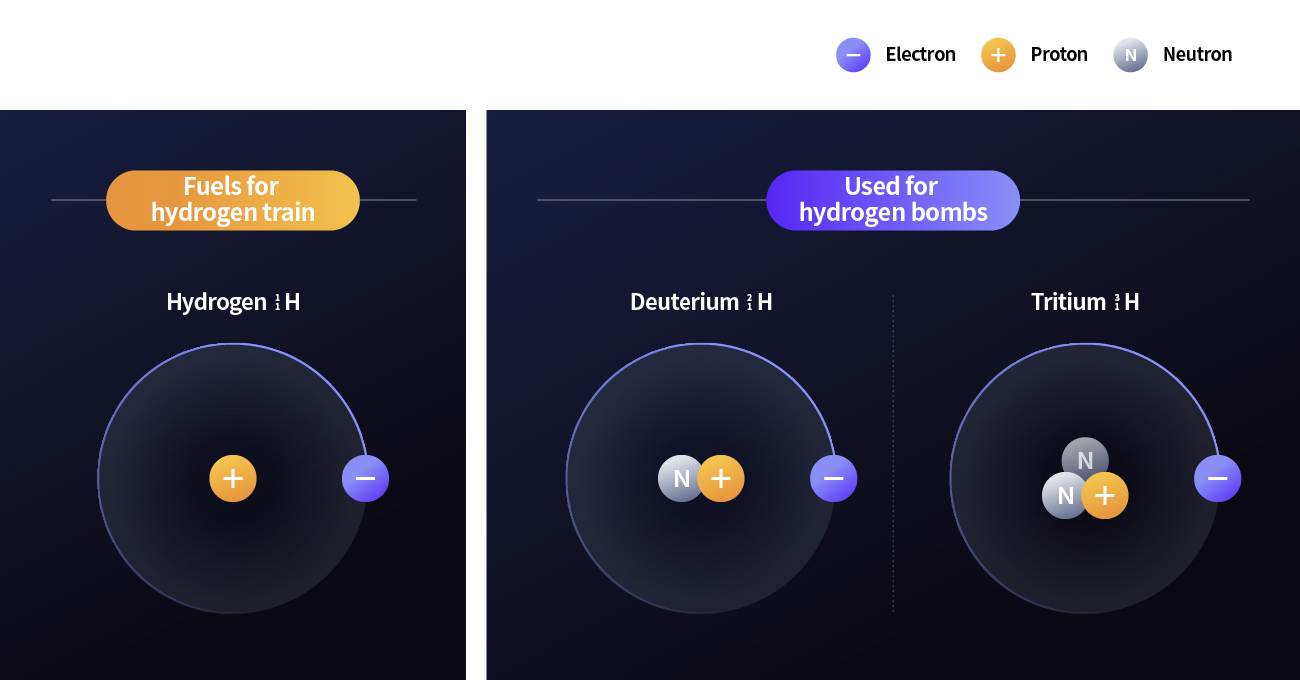

The reason for the rapid commercialization of hydrogen trains is the result of actively resolving the prejudice on the safety and stability of hydrogen, which was the biggest issue. One of the main reasons for the negative perception of hydrogen is that the word hydrogen is associated with a hydrogen bomb. However, the hydrogen used in the hydrogen train and the hydrogen in the hydrogen bomb are completely different substances. Hydrogen, which we commonly use as an energy source, including hydrogen trains, is a ‘hydrogen molecule’.

Hydrogen trains, which are currently in the commercialization stage, compress hydrogen molecules, store them in a tank at a pressure of about 700 bar, lower them to a low pressure, and send them to fuel cells to generate electricity through electrochemical reactions and use them as a power source. Hydrogen bombs, on the other hand, use deuterium and tritium, not hydrogen molecules. Deuterium and tritium cannot exist in nature because they require tremendous energy to form. Even if it exists, a high temperature of 100 million °C or more and a pressure of several thousand atmospheres are required to create the explosive power of a hydrogen bomb. It is necessary to detonate an atomic bomb to form temperature and atmospheric pressure to create a fusion environment for hydrogen bombs. On the other hand, hydrogen trains simply combine oxygen and hydrogen molecules to produce electricity and use it as energy.

Hydrogen is a safe source of energy compared to other energies we have been used. It is important how to manage all energy because it has the potential to explode. Hydrogen has already been used for a long time in various industries such as semiconductors, steel, chemicals, oil refining, and fertilizers, and safety management laws have been established. In fact, according to the relative risk of each fuel evaluated by the Korea Occupational Safety and Health Agency and the American Institute of Chemical Engineers, hydrogen is a safer energy than gasoline, LPG, or city gas that we are familiar with.

The safety assessment of pressure tank for hydrogen storage

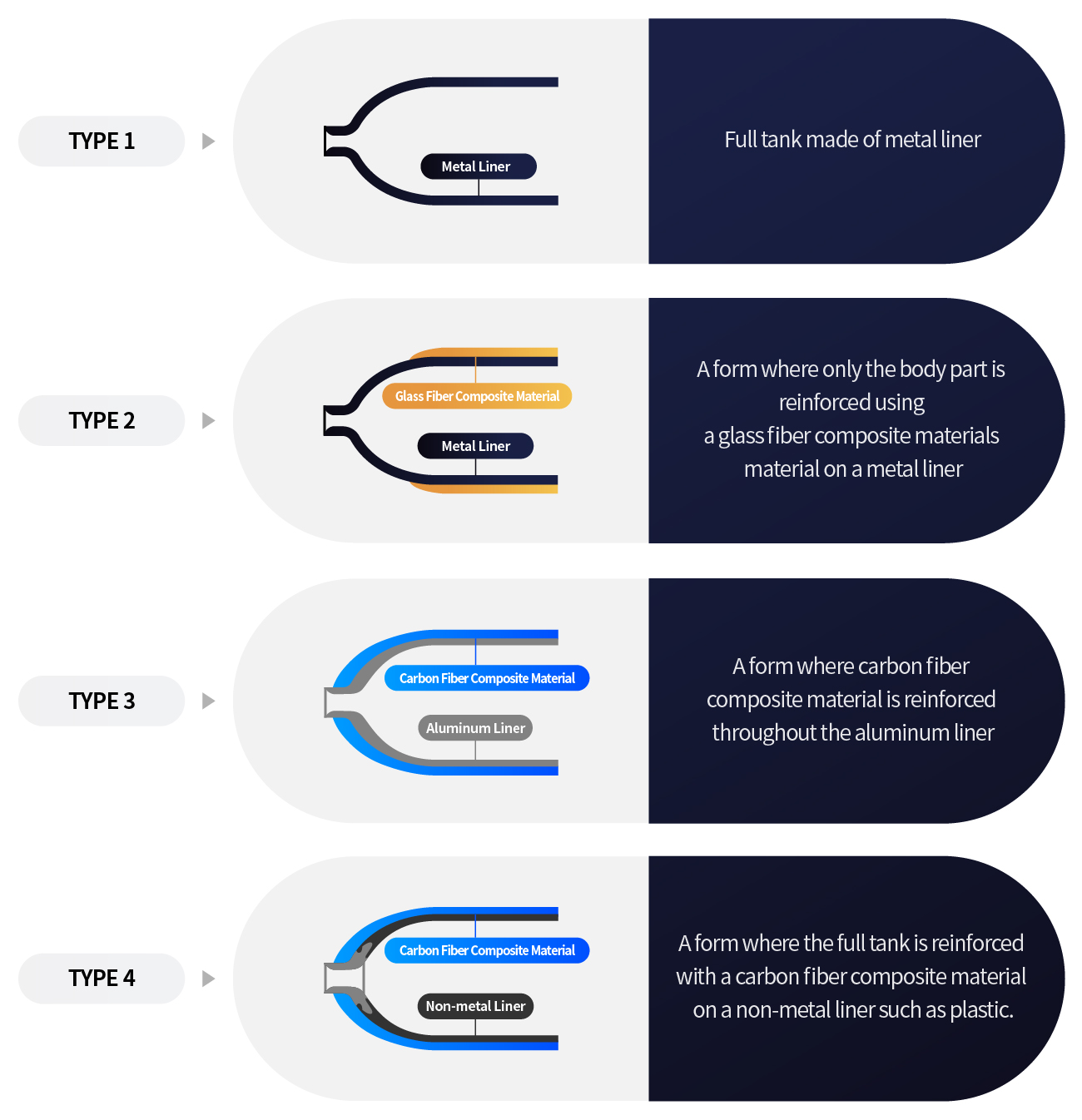

Of course, hydrogen is not a 100% safe energy source, so safe management is essential like other energy sources. Above all, it is very important for hydrogen to ensure the safety of the storage medium. This is because the process of compressing and storing hydrogen under high pressure is necessary to use it as an energy source. Therefore, it is necessary to enact and manage laws and regulations on the safety of pressure tanks for hydrogen storage to be mounted on trains to commercialize hydrogen trains in Korea. The most efficient way to secure the safety of the hydrogen storage tank of a hydrogen train is to use the hydrogen pressure tank of a hydrogen electric vehicles that have succeeded in commercialization through research and development for many years. Currently, hydrogen pressure tanks that are commonly used around the world are classified into four types as follows.

Type 1

In general, it is the type used in the most industrial groups, and it is a pressure tank made only of steel. It is made by manufacturing methods such as Mannesmann-spun type, Billet piercing, and deep drawing & ironing (DDI) Steel pressure tanks manufactured by applying a welding process are classified into Type 1 tanks in large categories. However, there are few cases where only a welding process is applied to a pressure tank for storing high-pressure gas. However, since the air pressure (10 to 11 bar) of railroad vehicles is not very high, pressure tanks made of the same material as Type 1 are mainly used.

Type 2

The pressure tank of Type 2 is characterized by reinforcing strength by wrapping glass fibers in the circumferential direction in a liner, which is the main body part, based on Type 1. Since the glass fiber and the liner share the pressure load of the pressure tank, the thickness of the pressure tank can be reduced compared to Type 1, and the weight is reduced by about 20%.

Type 3

Type 3 pressure tanks are basically made of aluminum, and they have a form where the liner is completely wrapped in the circumferential direction using carbon fibers and glass fibers. Like Type 2, the liner stores high-pressure gas and the composite material shares the pressure loads. However, the role of carbon fiber and glass fiber is slightly different. Carbon fibers share pressure loads, and glass fibers protect the carbon fiber film from external impacts. Type 3 reduces weight by about 60-70% compared to Type 1.

Type 4

Type 4 pressure tanks are usually made of plastic (non-metal). Like Type 3, the liner is completely wrapped with carbon fiber and glass fiber, and the liner only stores gas. The carbon fiber shares the pressure loads, the glass fiber protects the carbon fiber film from external impact, and the weight is reduced by about 60 to 70% compared to Type 1.

In general, hydrogen fueling stations use Type 1 or Type 2 with excellent economic efficiency. Type 3 and Type 4 have the advantage of safety in that only hydrogen leaks out of the tank as fragments of the tank are torn without splashing because they are wrapped in carbon fibers and glass fibers, but they have the disadvantage is that the production cost is expensive. In the case of currently commercialized hydrogen-powered trams, they focus on safety and use type 4 tanks. The hydrogen electric tram under development by Hyundai Rotem is also being developed by applying a type 4 pressure tank that have been verified for safety through commercialization of hydrogen electric vehicles.

The safety certification of hydrogen gas pressure tanks is being actively conducted in Europe in the fields of automobiles, buses, trucks, and plants. However, regulations for certification in the railroad and ship sectors are currently under review in Korea and oversea. It is also possible to consider applying a type approval system with EC79/EU406 (Type approach of hydrogen-powered motor vehicles) applied to the vehicle sector, such as buses, or ‘E-Mark’ certification, which is widely used as a certification in Europe.

What is E-Mark Certification?

It is a European compulsory type approval system to export automobiles, auto parts, and electronic equipment to Europe. In accordance with European ECE (European Economic Community) regulations, testing and assessment of automobile parts for LPG, CNG, and hydrogen fuel are exported by receiving certification marks through certification agencies. Certification is usually conducted through the tests. In particular, parts that use gases such as LPG, CNG, and hydrogen are checked for lifespan through strength and durability tests for safety against explosion. Some are tested to check the degree of damage allowed when used for a long time due to the nature of being exposed to the outside. In addition, tests are conducted to ensure safety even in extreme environments.

In Korea, the Korea Gas Safety Corporation, designated as a hydrogen safety institution in 2020, has started operating an inspection station to inspect the safety of hydrogen products in accordance with the Act on Hydrogen Economy Fostering and Hydrogen Safety Management (Hydrogen Act). The facility is conducting inspections on four types of products: water electrolysis facilities and hydrogen extraction facilities, which are hydrogen production products, and fixed and mobile fuel cells, which are hydrogen-using products. In addition, high-pressure gas facilities such as hydrogen fueling stations are required to install only hydrogen products that have passed the inspection. In addition, the Korea Gas Safety Corporation plans to build a pressure tank assessment facility for compressed hydrogen gas in hydrogen buses and start operation from June next year. Since the safety management of hydrogen pressure tanks is a very important task related to the safety of liquefied hydrogen facilities and hydrogen fuel cell facilities, which will become a core infrastructure of the hydrogen economy in the future, it is necessary to complete a more systematic safety management system, including pressure containers for hydrogen trains.

The conditions for commercialization of hydrogen trains, safety

Currently, Europe has established a long-term road map to replace existing diesel trains with hydrogen trains by 2030 through the ‘Hydrogen Europe’ project. From 2023 to 2025, hydrogen fuel will be applied first to locomotives for freight transportation, and by 2027, hydrogen-related standards will be established for these trains to operate across Europe. Finally, it plans to develop carbon-free system trains by 2030 and apply them to both freight and passenger trains.

Korea is also planning to introduce hydrogen trains through the announcement of a hydrogen economy revitalization roadmap. According to the hydrogen economy revitalization roadmap announced in 2019, Korea is expected to commercialize hydrogen trains before 2030 and promote overseas exports through R&D and demonstration. As Korea is sequentially developing trams and trains that use hydrogen as energy sources based on the technology of Korea, which was the first to commercialize hydrogen electric vehicles, it is expected that hydrogen trains operation on railroad will be seen in Korea soon.

However, the safety standards for hydrogen trains must be prepared and verified for hydrogen trains to be established in Korea and Europe and around the world. In Korea, it was impossible to even start verification because there were no separate regulations on pressure tanks and fuel devices for hydrogen trains under the current law. However, in October 2020, the regulatory exception review committee approved Hyundai Rotem’s hydrogen electric tram test operation, and the hydrogen electric tram concept car was released. In this way, the commercialization of hydrogen trains should be accelerated by cooperating with the public and private sectors to ensure safety verification that anyone can understand.