Hyundai Rotem participated in the ‘2025 RailLog Korea,’ held at BEXCO in Busan from June 18 to 21, showcasing its advanced localized railway technology capabilities. RailLog Korea is Korea’s largest railway exhibition held biennially, and this year’s 12th edition featured 137 companies from 17 countries with 951 booths, making it the largest in the event’s history.

As Korea’s leading comprehensive rail solution provider, Hyundai Rotem established the largest booth among participating companies at 2,700m², extensively showcasing localized railway technology capabilities built over the past 30 years—from hydrogen mobility to high-speed rail, export railway vehicles, train signaling systems, electrical components, and O&M exhibitions—presenting a blueprint for K-railway technology that will lead the global market.

The Bright Future of Hydrogen Mobility Beginning with Commercialized Hydrogen Fuel Cell Trams

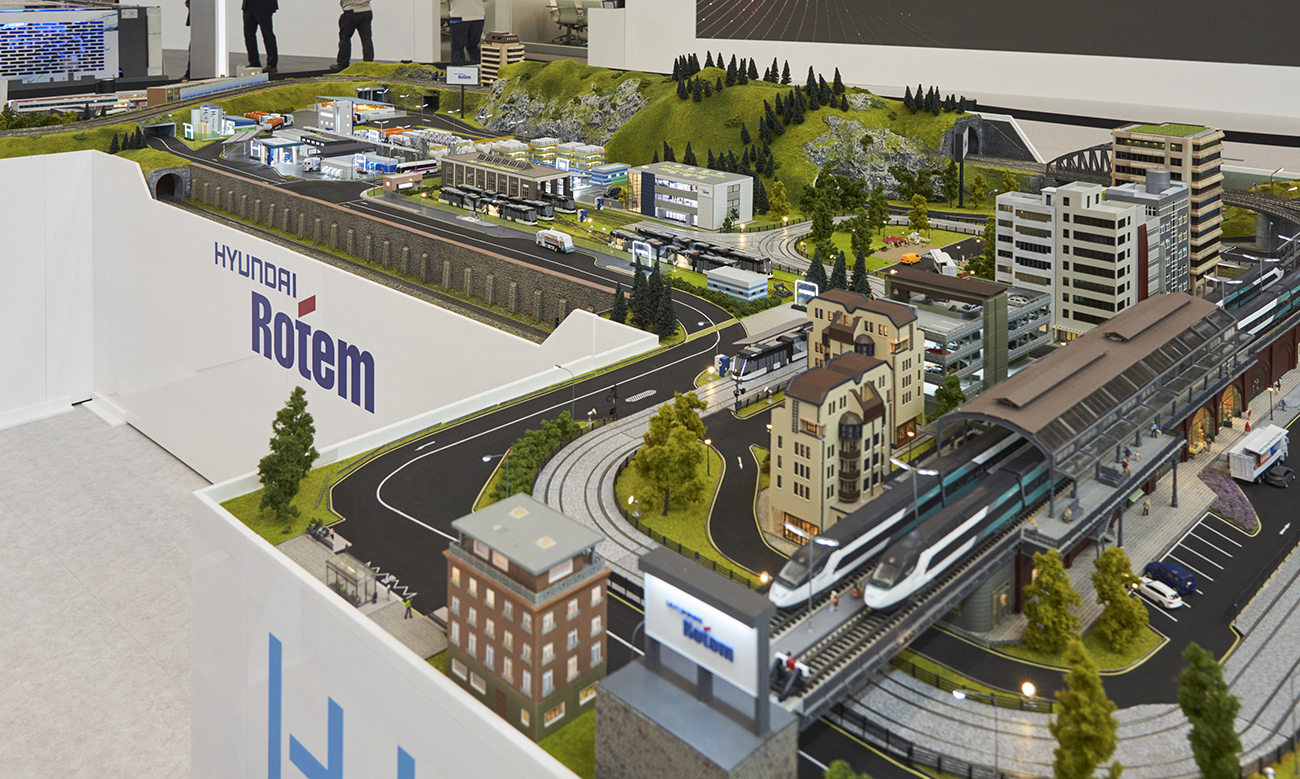

First, under the slogan “Connecting People and Technology to Create a Sustainable Future,” Hyundai Rotem presented a comprehensive hydrogen mobility roadmap beginning with Hydrogen Fuel Cell Trams. A large hydrogen society diorama showcasing the hydrogen value chain ecosystem being developed in partnership with Hyundai Motor Group was positioned at the center of the booth. This diorama, first unveiled at the 2024 InnoTrans exhibition in Germany, allowed visitors to witness the hydrogen society spanning from hydrogen production through storage, transport, and utilization, as well as various hydrogen mobility solutions traversing urban areas.

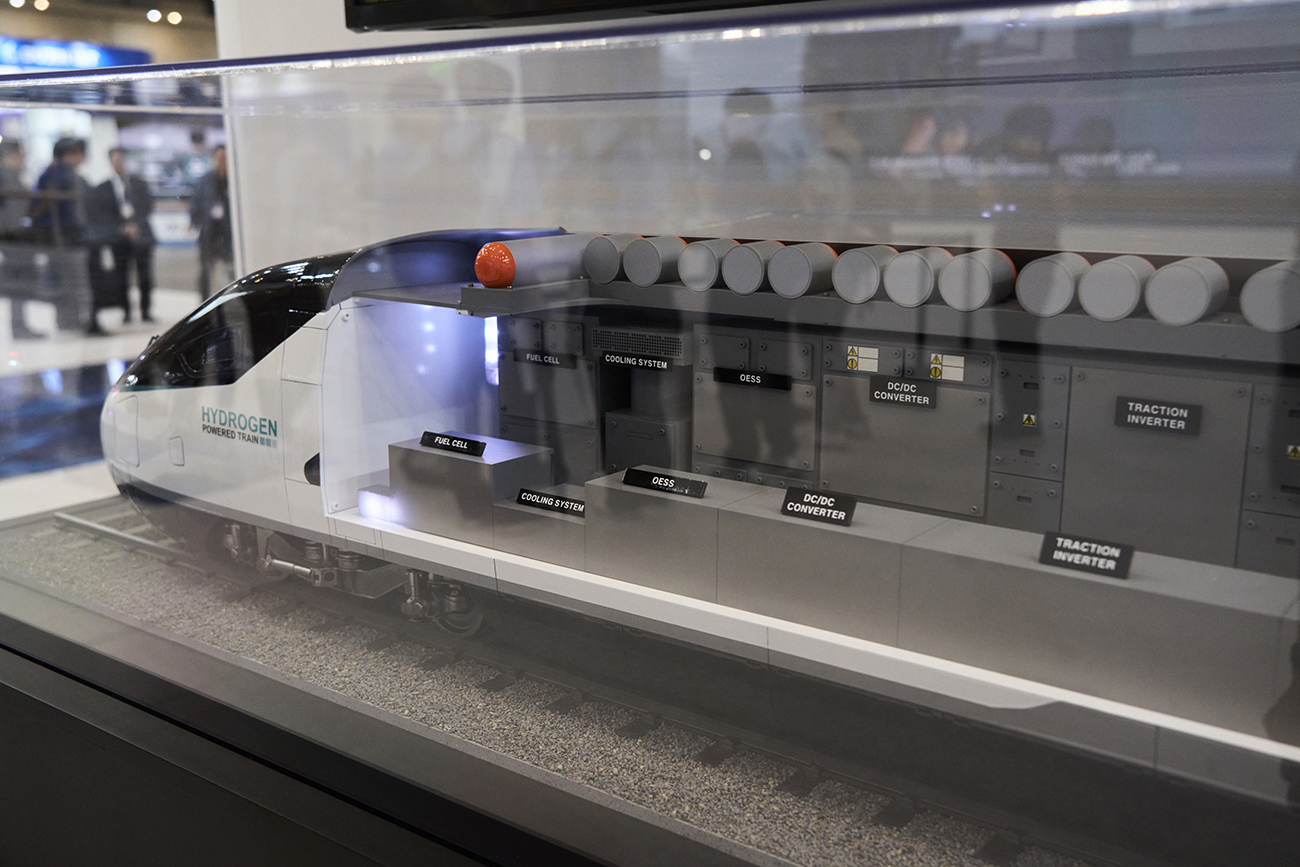

Two years ago at the RailLog Korea, Hyundai Rotem displayed a Hydrogen Fuel Cell Tram demonstration vehicle model, heralding the dawn of the hydrogen mobility era. This year, the company focused on promoting commercialized Hydrogen Fuel Cell Tram technology by introducing the actual flat-type hydrogen fuel cell power system. The flat-type hydrogen fuel cell power system unveiled this time will be applied to the Hydrogen Fuel Cell Trams for Daejeon Urban Railway Line 2, scheduled to open in 2028. The system features a modularized design that reduces the height of conventional fuel cells used in hydrogen cars or commercial vehicles, combining two units into one, making it suitable for specialized vehicles such as railway vehicles (trams, trains, etc.) or city/regional buses with space constraints for fuel cell installation.

Hyundai Rotem’s Hydrogen Fuel Cell Tram is Korea’s first commercialized tram model, combining four 95kW flat-type hydrogen fuel cells to produce 380kW output, achieving a maximum speed of 70km/h and a maximum operating range of over 200km. The hydrogen storage tank capacity has been doubled from the commercialized model’s 42kg·1050L to 84kg·2100L. Safety and operating performance were validated through demonstration operations on the Ulsan Port Line in 2023. In 2024, Hyundai Rotem signed a 293.4 billion won supply contract with Daejeon City covering the production of 34 hydrogen fuel cell trams, signaling systems, and maintenance facilities, with deliveries scheduled to begin in 2026 and continue sequentially through the first half of 2028.

This event also provided an opportunity to glimpse how hydrogen mobility technology, successfully commercialized through Hydrogen Fuel Cell Trams, might develop in the future. These were the low-floor hydrogen electric multiple unit(EMU) and hydrogen powered train displayed as miniature models. The low-floor hydrogen EMU can serve as commuter and mainline vehicles targeting a design maximum speed of 110km/h and an operating range of over 500km, while the hydrogen powered train is a medium-to-long-distance train model featuring a 6-car configuration with design maximum speeds of 220km/h (above ground) and 160km/h (underground), an operating range of over 600km, and a total passenger capacity of 568 people.

The hydrogen powered car attracted even greater attention as it is scheduled to be applied to the Busan Train Express (BuTX) project being promoted by Busan City. BuTX is characterized by operating in deep underground tunnels at depths of 40m or more along a total 54km route from Gadeokdo New Airport to the Osiria Tourism Complex. Hyundai Rotem plans to deploy hydrogen powered trains equipped with a total of six flat-type hydrogen fuel cell power systems to significantly enhance performance in terms of output and operating range for BuTX.

At this exhibition, Hyundai Rotem focused on promoting not only BuTX models and technology but also the overall project. Moreover, since BuTX represents a comprehensive integration of deep underground GTX (Great Train eXpress) technology supplied by Hyundai Rotem and Hydrogen Fuel Cell Tram technology for Daejeon Line 2 scheduled to open in 2028, the exhibition content generated even greater expectations for future prospects.

Korean High-Speed Trains Confidently Enter the Global Market with Superior Performance

The left side of the booth was filled with content about high-speed trains that have been building a solid position in domestic and international markets since localization. First, the separately established ‘Heritage Hall’ allowed visitors to explore the history and technological development achievements of Korean high-speed trains spanning over 30 years, from the Korean high-speed vehicle G7 development project that began in 1996 to the development of the Korean high-speed test vehicle HEMU-430X in 2012.

Hyundai Rotem’s history of developing localized high-speed trains, which began with signing a high-speed train technology transfer agreement with France’s Alstom in 1994, flourished through the G7 development project that started in 1996 and was completed in 2007. The G7 development subsequently led to the commercialization of KTX-Sancheon (2010), Korea’s first domestically produced high-speed train, and Hyundai Rotem became the world’s fourth railway manufacturing company to secure proprietary power-concentrated high-speed vehicle technology.

At the front of the Heritage Hall, visitors could directly witness the fruits of Korean high-speed train commercialization. The first domestically produced high-speed train KTX-Sancheon, the latest Korean high-speed train KTX-Cheongryong that entered commercial operation in 2024, and the next-generation high-speed train EMU-370 currently under intensive core technology R&D were displayed as miniature models along with vehicle introduction content. EMU-370 is the successor model to the power distributed high-speed train KTX-Eum and KTX-Cheongryong, featuring optimized streamlined front ends and minimized rooftop protruding structures to improve upper airflow in order to minimize air resistance and aerodynamic noise generated by increased speeds up to 370km/h. Hyundai Rotem plans to complete the development of EMU-370 core technology within this year.

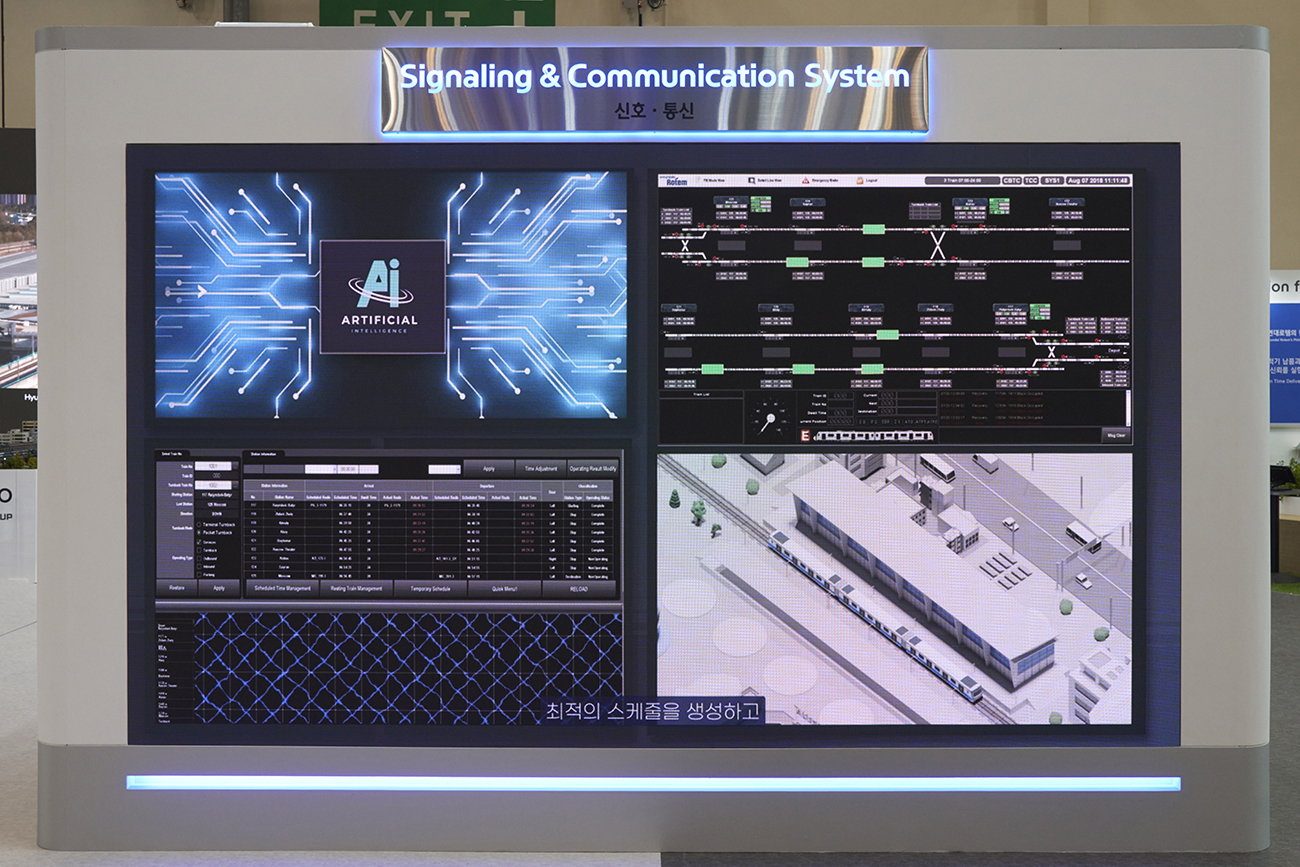

The highlight of the high-speed train exhibition occupying the large space on the left side of the booth was the major core components of high-speed trains. These included bogies, traction converter, traction motor, and auxiliary power supply—all systems to be applied to high-speed trains in Uzbekistan. The bogie frame is a device with a critical speed of over 450km/h that meets both European standards (EN14363, EN13749) and Korean Railway Vehicle Technical Standards (KRTS-VE-Part31). The water-cooled propulsion control device consists of a converter with a rated capacity of 1710kW and an inverter of 1900kVA, while the traction motor has an output of 380kW. The auxiliary power unit delivers performance of 250kVA for AC output and 160kW for DC output respectively.

Hyundai Rotem signed a contract in 2024 to supply 42 cars (6 trainsets) of 250km/h-class power distributed high-speed trains to Uzbekistan. This was the result of high evaluation by Uzbekistan Railways, which commissioned the project, of the transport capacity and passenger convenience of Korea’s distributed traction high-speed trains based on EMU-260 (KTX-Eum).

The Uzbekistan high-speed train project contract, recorded as the first overseas market entry for domestically produced high-speed trains, is highly significant in that Hyundai Rotem’s high-speed train manufacturing technology and operational track record built in Korea has been recognized internationally. The localization rate of Hyundai Rotem high-speed train components is close to 90%, which is the result of close collaboration with the domestic railway parts industry from the early stages of the KTX-Sancheon development project. With this as a catalyst, if high-speed train exports expand worldwide in the future, it is expected to bring new business expansion opportunities not only to Hyundai Rotem but also to the entire domestic railway industry.

Hyundai Rotem Transformed into a Total Solution Company Covering Everything from Vehicles to Core Components and Maintenance

Hyundai Rotem also displayed three types of actual trains (Airport Railroad EMU, Taiwan Taoyuan Green Line EMU, and Canadian Edmonton tram) befitting Korea’s only and largest railway technology exhibition, providing special enjoyment to visitors.

While the protagonists of the event two years ago were vehicles nearing commercialization at the time—such as GTX-A trains, EMU-320, and Hydrogen Fuel Cell Trams—this year focused more on the present state of K-railway implemented by Hyundai Rotem by featuring vehicles that will enter commercial operation domestically and internationally after testing.

Airport Railroad Corporation plans to sequentially put 9 new Airport Railroad EMU trainsets manufactured by Hyundai Rotem into commercial operation by the end of this year to alleviate congestion and increase transport capacity, while the Taiwan Taoyuan Green Line automated transit system began delivery of the first trainset at the end of December 2024, with a total of 80 cars scheduled to be supplied by 2029.

The Canadian Edmonton tram that Hyundai Rotem plans to deliver by 2027 consists of 7 modules per trainset with a maximum operating speed of 80km/h. Hyundai Rotem has demonstrated competitiveness in the overseas tram market, starting with Türkiye Antalya trams (18 trainsets) and Türkiye Izmir trams (38 trainsets) in 2014, followed by successful orders for 123 trainsets for Poland Warsaw trams in 2019 and 40 trainsets for Canadian Edmonton trams in 2021.

Particularly at this year’s exhibition, small presentation sessions on high-speed vehicle core components (electrical equipment and signaling systems) and operation & maintenance (O&M) technical expertise were held four times daily during the event period, allowing confirmation of Hyundai Rotem’s current position as it evolves into a comprehensive rail solution provider.

The 2025 RailLog Korea was an occasion that fully conveyed the status of K-railway expanding globally. Above all, Hyundai Rotem demonstrated remarkable achievements in the two years since the 2023 exhibition, including the commercialization of hydrogen mobility and the first overseas export of high-speed trains. The future of Hyundai Rotem, which is transforming from a representative K-railway company into a competitive global comprehensive rail solution provider, is even more promising.