Hyundai Rotem undertook research and development for a smart maintenance system in 2018 and finally developed a real time train monitoring and big data analysis platform that allows condition based maintenance (CBM) and predictive maintenance. The platform is connected to various sensors and data collection devices by IoT technology and gathers and analyzes data of trains real time, enabling users to take immediate actions as needed and facilitating smart operation and maintenance. It addresses the previous shortcoming in regular maintenance system and reduces the maintenance cost by optimizing fleet maintenance intervals. Reducing the maintenance cost is most important above all as it accounts for approximately 30% of the total cost required from purchasing to scrapping of trains.

Real time monitoring platform that shows the trains’ big data at a glance

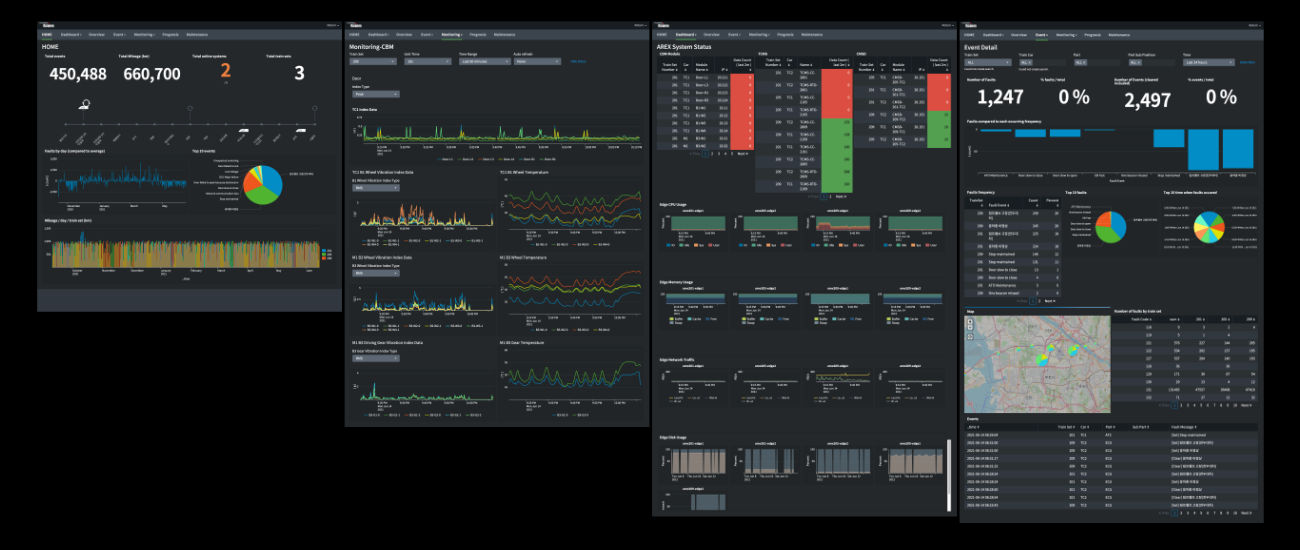

Advances in various sensors, IoT and 5G wireless networks have created an environment where a large amount of data could be collected on trains’ operation, failure and condition real time. What’s important is of course to preprocess, analyze and visualize the large amount of data in a proper form to facilitate a user’s understanding and utilization. Thus, Hyundai Rotem has developed a cloud-based train big data analysis and data visualization platform.

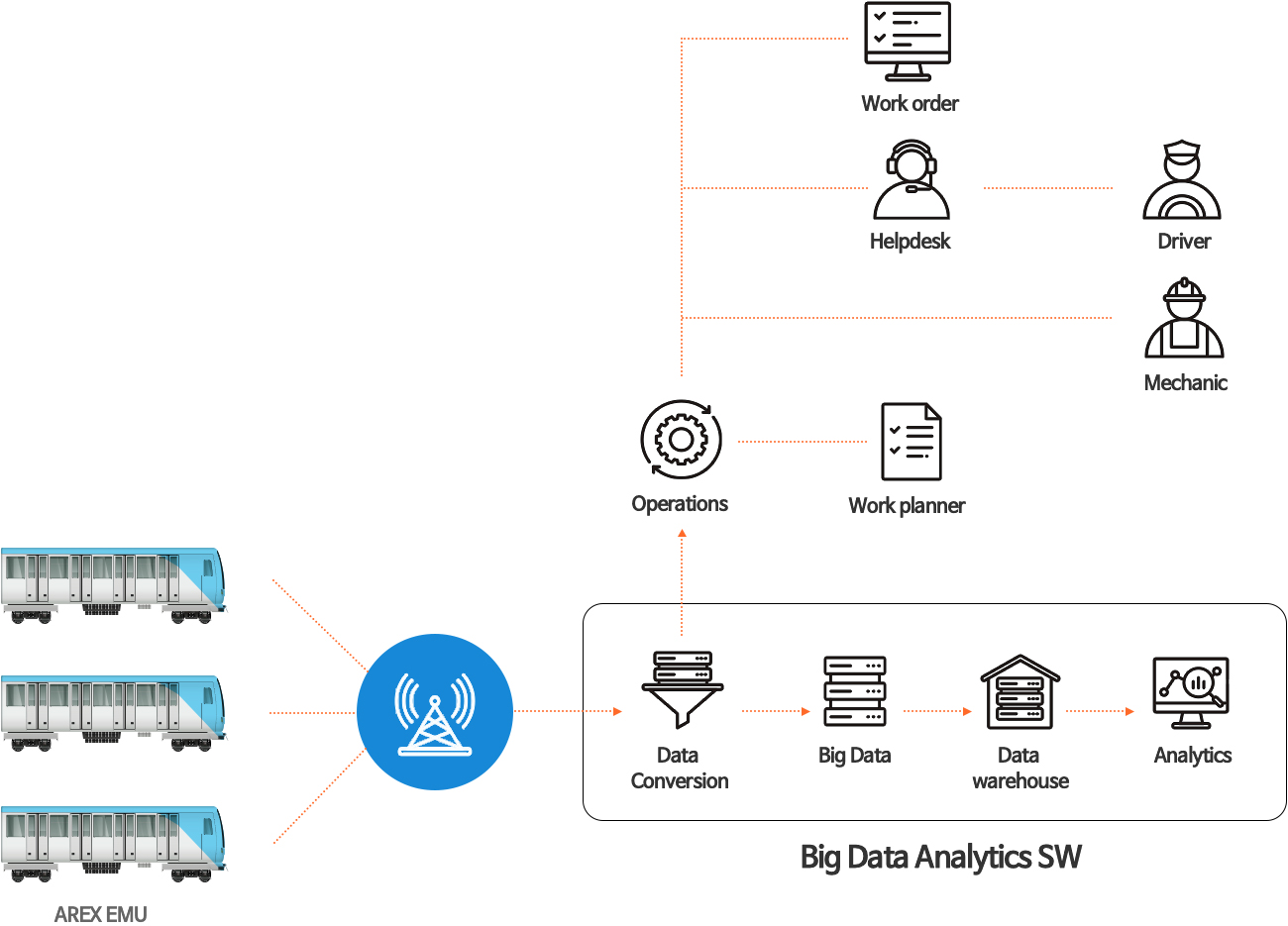

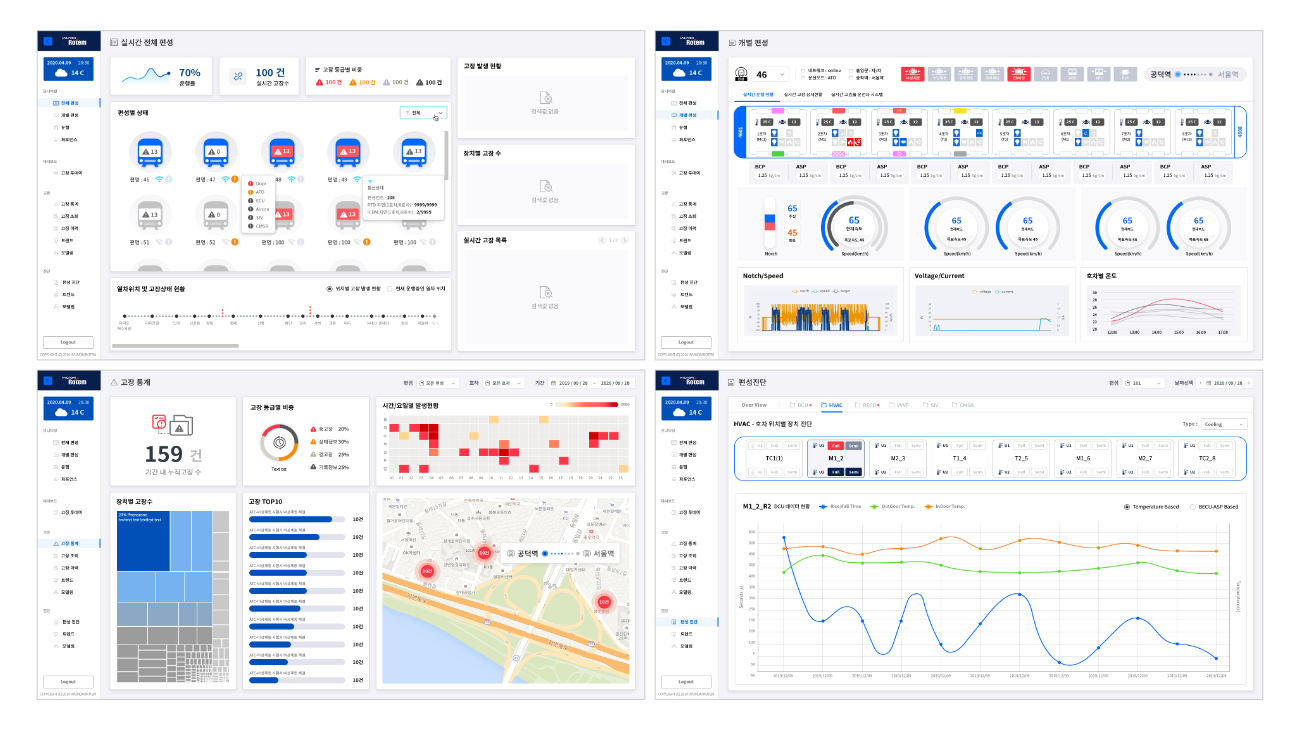

The real time train monitoring and big data analysis platform is a solution to provide users (operations and maintenance mechanics) with assistance in their work by utilizing big data collected from train. It provides information on the trains’ operations/failure and current condition real time and uses the train’s operating data for the operating plan establishment and operations management and the failure data for the train’s maintenance plan establishment. Such data are analyzed together with maintenance inspection results to identify potential failures of trains. Accordingly, an efficient maintenance schedule can be developed. In addition, it detects and shows the trains’ defect and failure on the platform screen and sends an e-mail or text to the operators and maintenance mechanics.

Through the alarm on the defect or failure, the operators can take necessary actions with the drivers efficiently. Also, unexpected sudden failures can be quickly addressed based on accumulated data on previous actions on failures. Furthermore, it can maximize trains’ availability as maintenance mechanics can diagnose trains’ condition before any defect or failure occurs and when there is a defect or failure, they can prepare for a repair before the train comes into the depot and perform the repair immediately on arrival.

Big data analysis platform applied to an AREX (Airport Express) on trial

Real time train diagnosis monitoring platform to be applied to Busan Metro.

Hyundai Rotem’s real time train monitoring and big data analysis platform is expected to have the following effects: Firstly, it enables users to extend a component’s replacement intervals and reduce maintenance costs by predicting a component’s remaining life. Secondly, it enables users to perform timely preventive inspections and improve the trains’ durability by analyzing abnormality frequency through tracking management of failure and accident data. Lastly, it can build a flexible server infrastructure, including the cloud, for monitoring and analyzing various types of trains and facilities.

In view of this, Hyundai Rotem initiated the development of a logic and algorithm that diagnose the condition of main devices last year and improved the perfection level of the solution through data visualization. They also considered the design and custom setting for each user in the visualization process through an analysis of use cases. The strong point is that it is applicable to any train or facility so long as there is a data collection infrastructure since it runs web-based.

Big data analysis solution supports the stable operation with a cloud base

Hyundai Rotem’s big data analysis platform bases on the cloud, which is a virtual data storage space. Unlike a physical server, the cloud has no risk of data loss from hardware damage and requires less costs for data storage and preservation due to less restrictions such as limitation of storage space. Accordingly, Hyundai Rotem develops a database inside the cloud with Naver Cloud. They already developed a platform service with an independent physical server in preparation for potential users’ needs.

They also plan to apply edge cloud computing that improves data security, accessibility and convenience by dispersing the cloud. Edge cloud computing can provide services for passengers, while the cloud-based CBM system provides maintenance services for users (maintenance mechanics). For example, passengers can check boarding locations or passenger congestion on a mobile app real time. Also, they are utilizing the cloud database technology in a “real time high efficiency operator support system.” The solution provides a suggestion for the most efficient operating pattern using track data, in addition to the trains’ condition data.

The cloud-based big data analysis solution and real time monitoring diagnosis solution that are applied to Hyundai Rotem’s smart maintenance system are essentially required solutions to reduce failures and preventive inspection costs gradually and improve the availability of trains. Hyundai Rotem has advanced the systems by adding industry 4.0 key technologies such as big data and cloud technology to provide optimized services.

When building a new system in the cloud, the entire project period can be reduced up to 85% from acquisition to verification of the system. Hyundai Rotem is planning to continue on smart maintenance technology development to provide a better transportation environment to operators and further to passengers. Thus, their future performance is expected to be outstanding in both of the domestic and overseas railway markets.