The whole world is running towards de-carbonization in 2050. The upsurge in green-house gases after industrialization has increased the global temperature continuously, bringing abnormal climate changes as a side effect. To address the problems, countries all over the world concluded the United Nations Framework Convention on Climate Change (UNFCCC) that restricts green-house gas emissions, including carbon dioxide to prevent global warming and agreed to control the average global temperature under 1.5℃ as before industrialization to achieve de-carbonization by 2050. In addition, they announced their plans on making more aggressive and practical policies to reduce green-house gas emissions.

In line with this, companies around the world are keeping pace with the policies. Efforts have been continuously made to reduce green-house gas emissions in the entire industry across the board from product life cycle to service. Among them, carbon footprints used to measure low-carbon products by indicating and controlling green-house gas emissions in numerical figures is the most common. Such efforts are also being made in the transportation industry that accounts for around 21% of the global green-house gases. Hyundai Rotem leading the domestic railway industry is improving the design and manufacturing methods of trains by calculating and evaluating the carbon emissions in each stage of its life cycle to make more eco-friendly trains.

What is carbon footprint?

As we leave a trail in a path we take, we leave green-house gases in manufacturing, using and discarding a product. Carbon footprint is an indicator of green-house gas emissions. In particular, international organizations and governments of countries across the world pay attention to carbon dioxide (CO2). It is because it accounts for around 80% of the green-house gases generated by our actions. To minimize the rise in the global temperature and abnormal climate changes therefrom, carbon dioxide emissions must be reduced. For reference, de-carbonization, carbon zero, carbon neutrality and net zero are the indicators used to balance the emission and absorption close to 0, not to completely eliminate it from all activities.

Changes in the transportation industry are essential to achieve carbon neutrality by 2050. Green-house gas emissions in the transportation industry have been constantly increasing for years. According to the data of two environmental organizations, Intergovernmental Panel on Climate Change (IPCC) and Our World in Data, the global green-house gas emissions from the transportation industry increased from 14% in 2010 to 16.2% in 2016. For reference, the global carbon dioxide emissions have increased by 1.9% annually since 2000. According to the International Energy Agency (IEA), carbon emissions have increased by about 0.5% despite the lockdown and travel restrictions in Europe and America caused by the outbreak of Covid-19. In other words, carbon neutrality is not possible without active engagement of the transportation industry.

Carbon footprint of trains, a pre-eminent means of transportation

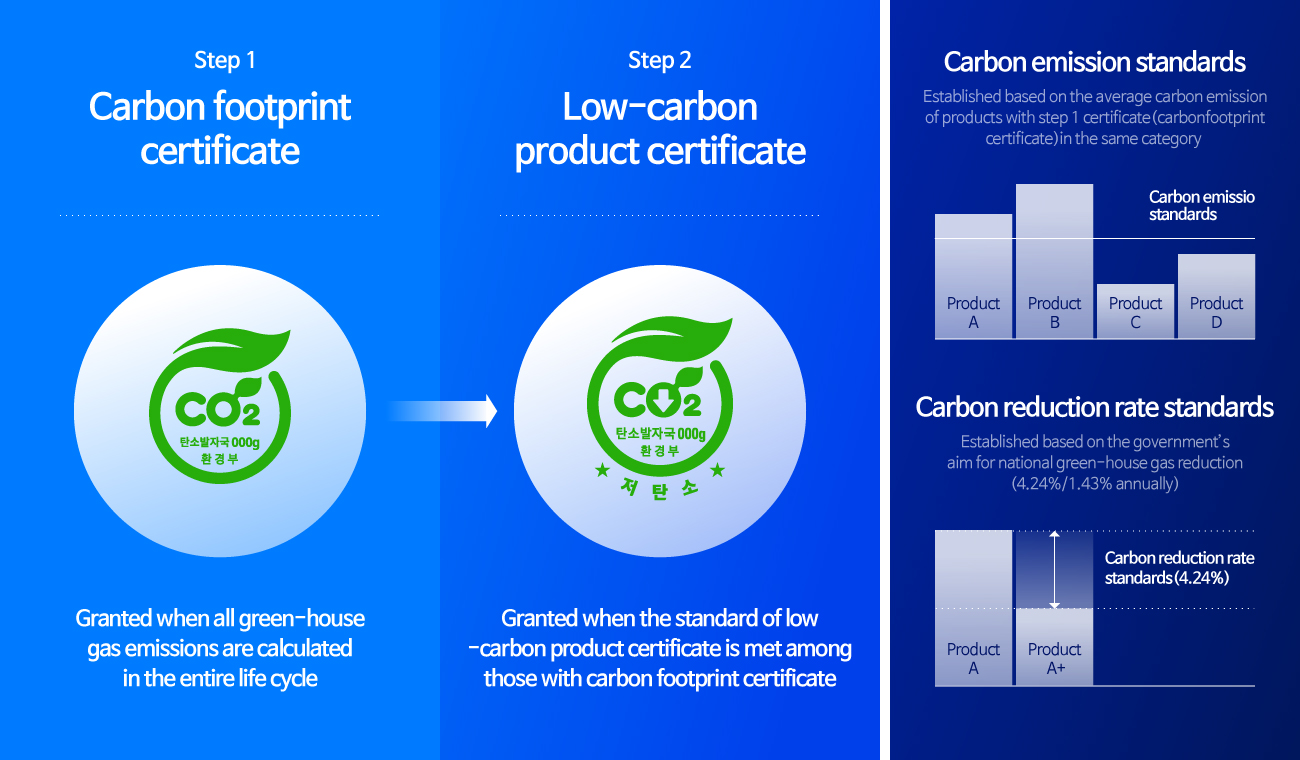

Carbon footprint certification step

Carbon footprint certification, which indicates the effect of carbon, (green-house gases) generated in the entire process of products and services from materials collection to production, transport, distribution, use and disposal, on climate changes qualitatively, is issued in the form of labels and placed on products. The certification consists of two steps; step 1 carbon footprint certificate, step 2 low-carbon product certificate. The carbon footprint certificate is issued to products when all green-house gas emissions are calculated from production to disposal, while the low-carbon product certificate is issued to products when the green-house gas emissions are below the average emissions of the products in the same category and reduced by 4.24% using a low-carbon technology.

Carbon footprint by means of transportation

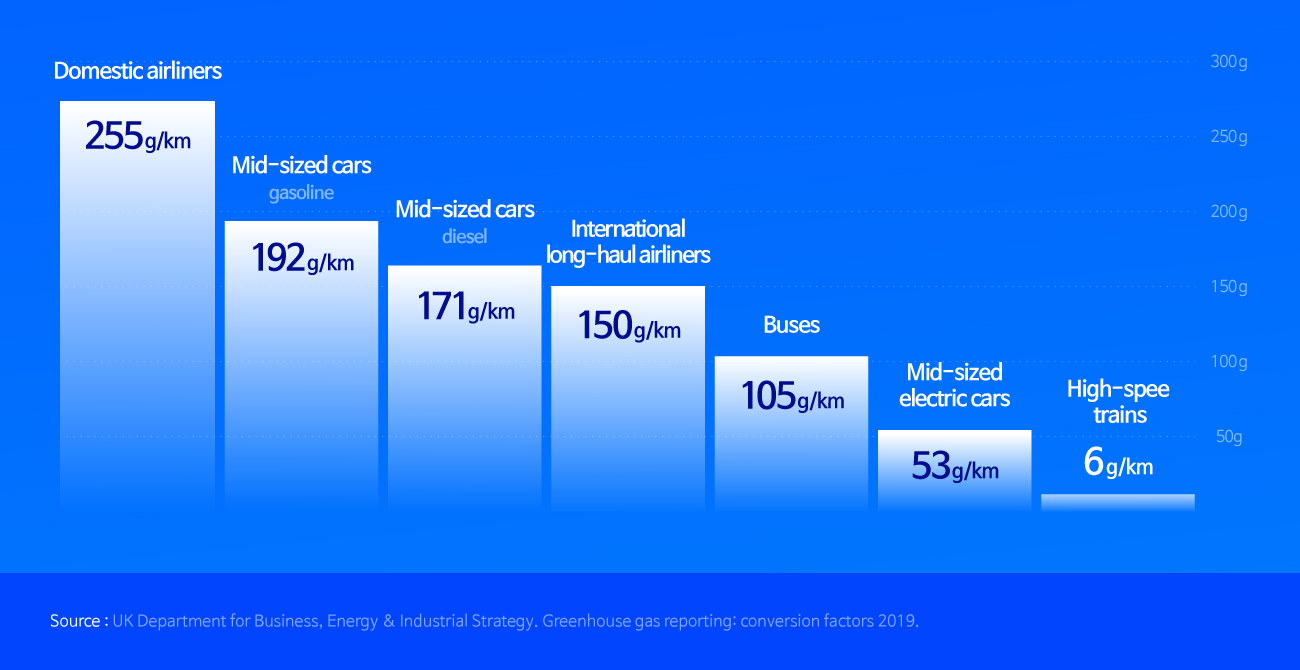

In the transportation industry, trains are moving the fastest towards carbon neutrality. It is proven by many researches and surveys of institutions. For example, a report on green-house gases by the UK Department for Business, Energy and Industrial Strategy shows that among airliners, cars (mid-sized), buses and high-speed trains, high-speed trains produce the least amount of carbon. A report by the Europe Union Agency for Railway (ERA) also shows an outstanding result of trains in environmental impact assessment compared to the other means of transportation.

Moreover, investigation by Lufthansa Innovation Hub and Travel and Mobility Tech (TNMT) revealed that motorbikes and cars produce carbon several times more than trains. For example, KTX Seoul-Gangneung trains produce carbon 16.0kgCO2 per person, which is half that of cars, 29.91kgCO2. Thus, taking KTX, instead of cars, can minimize the effect on the atmospheric environment when going to Gangneung. Korail proved the KTX Gangneung trains are eco-friendly by obtaining the carbon footprint certificate on the transportation service of the trains in 2020.

Eco-friendly trains that produce less carbon dioxide and use eco-friendly resources are increasingly being demanded. Environmental impact assessment of trains in the entire process that first began in the Europe is being expanded across the globe gradually. Furthermore, it is more often that customers are provided with environmental information on trains obtained through environmental impact assessment and that the environmental impact of trains is compared with that of other means of transportation.

What is life cycle assessment (LCA)?

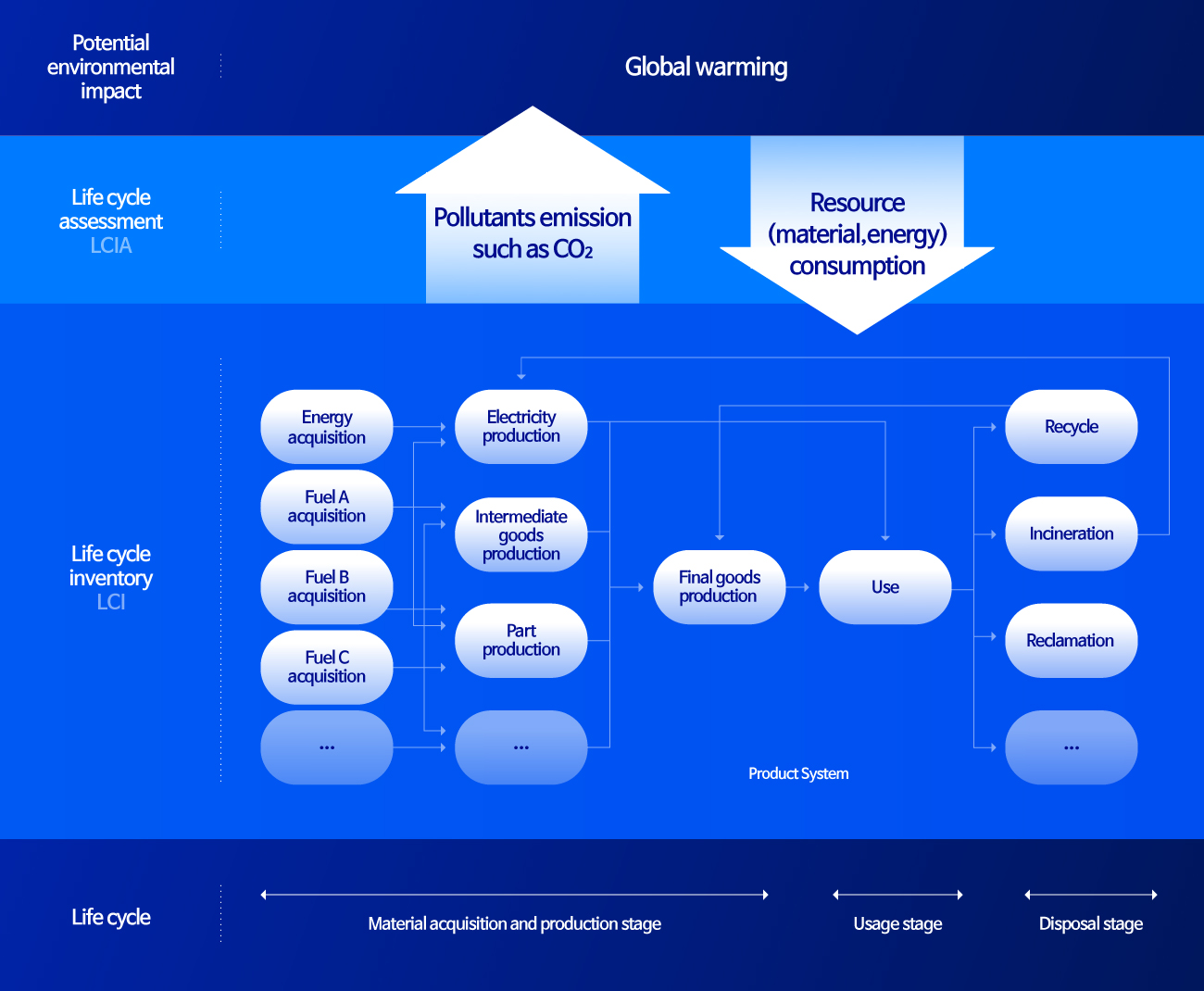

Overview of Life Cycle Assessment

The life cycle of trains starts from materials (natural resource) collection to materials processing, parts manufacture, transportation, train manufacture, operations and ends with disposal such as re-use, recycling, incineration and reclamation in this order. Life cycle assessment is a tool to systematically assess the potential environmental impact in the said processes by investigating the used resources and energies and pollutants qualitatively. It is a method to assess the environmental impact such as global warming, resource consumption, ozone layer, oxidization, eutrophication and photochemical oxide generation. For reference, global warming refers to all quantified green-house gases such as carbon dioxide and methane. Life cycle assessment of trains calculates the carbon dioxide emissions from trains. For this, Hyundai Rotem has the following aims and plans:

• To collect data on carbon dioxide emissions in the train manufacture process

• To set up a carbon dioxide emission factor and database of the materials of trains

• To formulate a usage and disposal scenario and collect data on carbon dioxide emissions

To this end, the weight and proportion of raw and subsidiary materials used in the train design process will be analyzed based on the bill of materials (BOM) with reference to the flowchart of the manufacturing process. Carbon dioxide emissions will be calculated, including the raw and subsidiary materials used by the 1st partners, as well. Trains can obtain the carbon footprint certificate through the assessment and low-carbon product certificate through carbon emission assessment.

Hyundai Rotem’s carbon emission calculation method

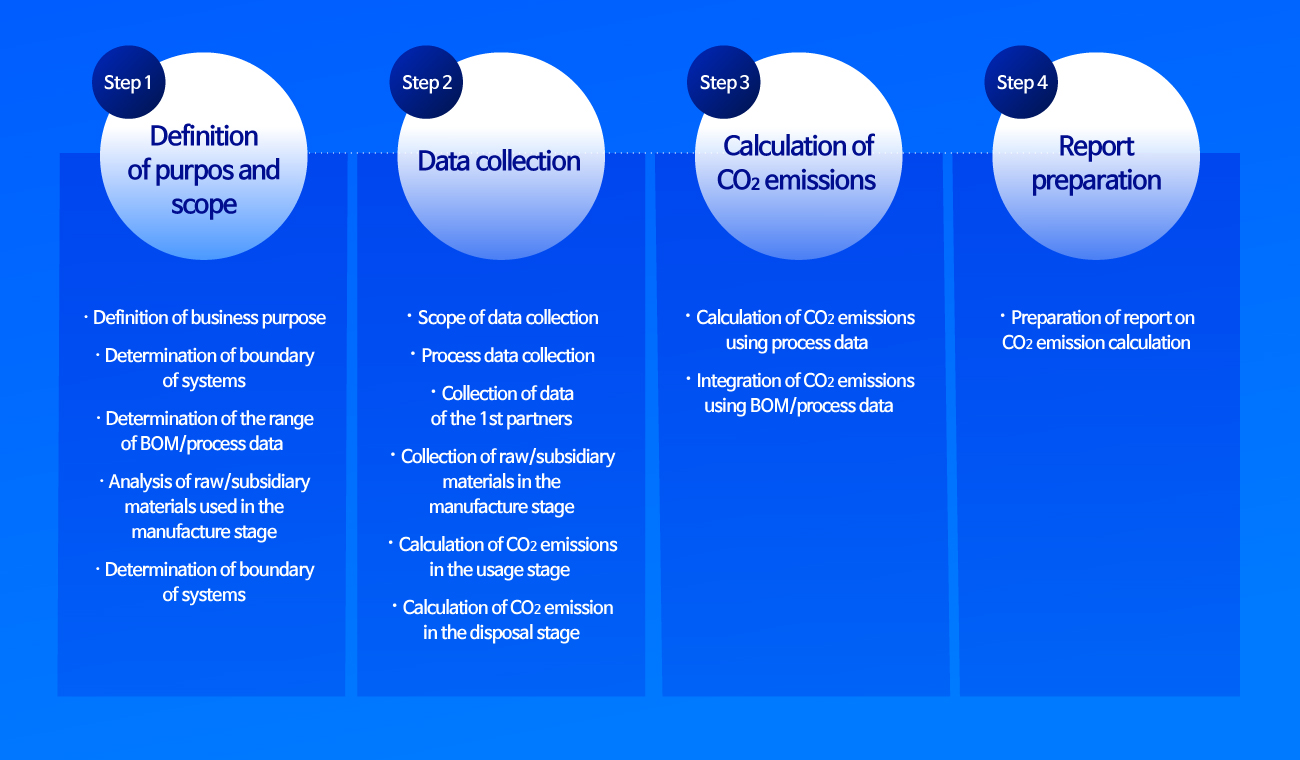

Carbon dioxide emission calculation in 4 steps

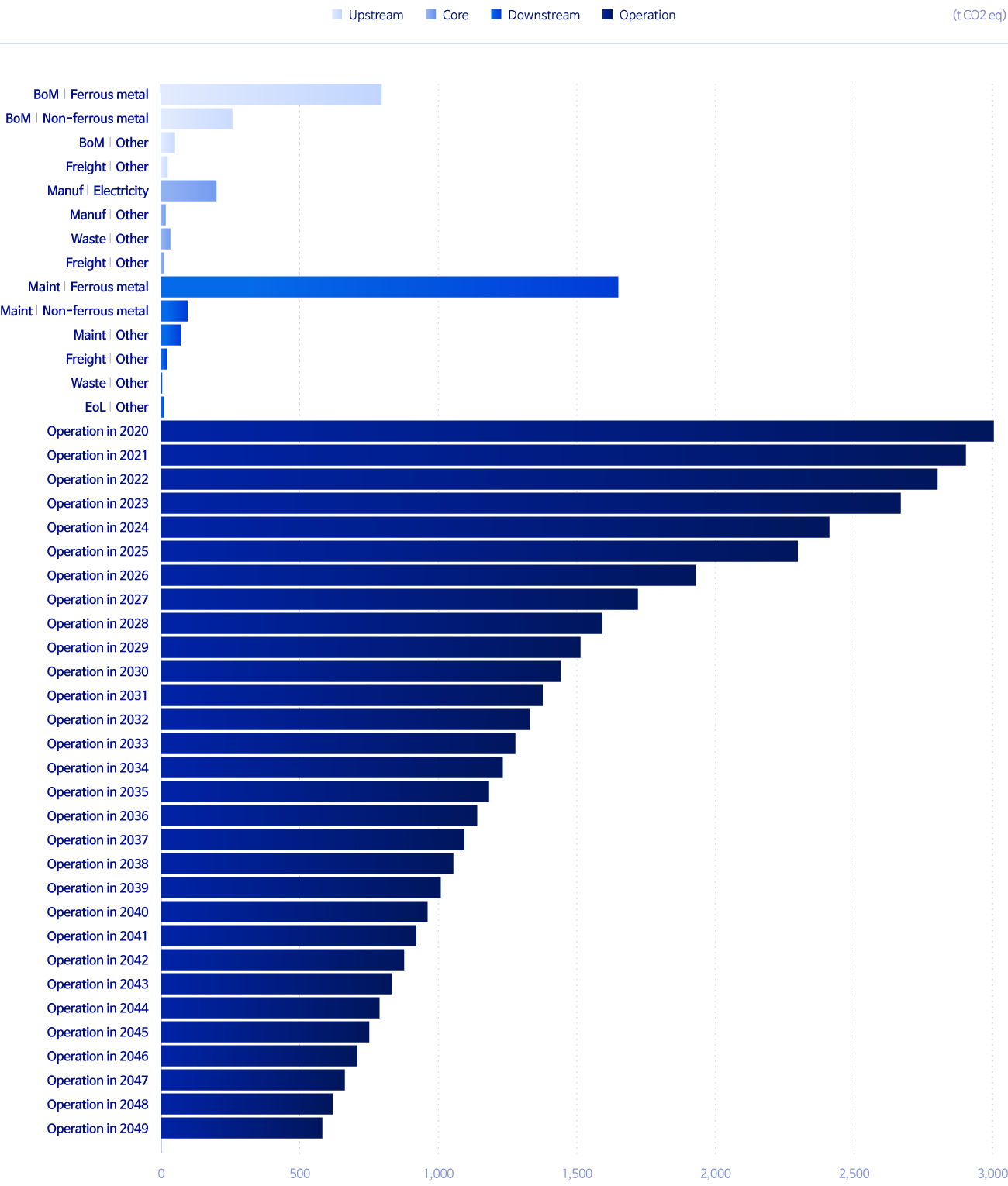

Hyundai Rotem calculates carbon emissions from trains systematically in four steps. In step 1, the purpose and scope of research are established and the global warming potential (GWP) is determined through life cycle assessment of trains. In step 2, data are collected comprehensively from the used raw materials and energy to waste and disposal, in addition to data of electricity supplied to trains during operating periods. In step 3, mass, volume and energy consumption data that affect global warming are gathered. Finally, in step 4, the final carbon dioxide emissions are calculated by calculating carbon dioxide emissions in each stage of the life cycle and in future operations. Recently, Hyundai Rotem calculated the carbon emissions from EMUs that are exported abroad through the life cycle assessment using the four steps. Carbon emissions were reduced to around a half the initial goal through the assessment.

Global warming potential by stage of life cycle

In calculating the carbon emissions in the life cycle of trains, Hyundai Rotem uses the BOM of trains and weight and proportion value of raw materials used for weight control in the design stage. The accurately calculated weight data are useful in calculating carbon emissions in the life cycle of trains. Railway operators can control the green-house gas emissions generated during train operation and purchase carbon credits as necessary.

Additionally, Hyundai Rotem is developing hydrogen electric tram that are powered by hydrogen for cleaner transportation and zero carbon emission. As the Korea’s representative train manufacturer, Hyundai Rotem continues to make efforts to position trains as a eco-friendlier transport.