Hyperloop, the ‘Dream Transportation’ Faster than an Airplane

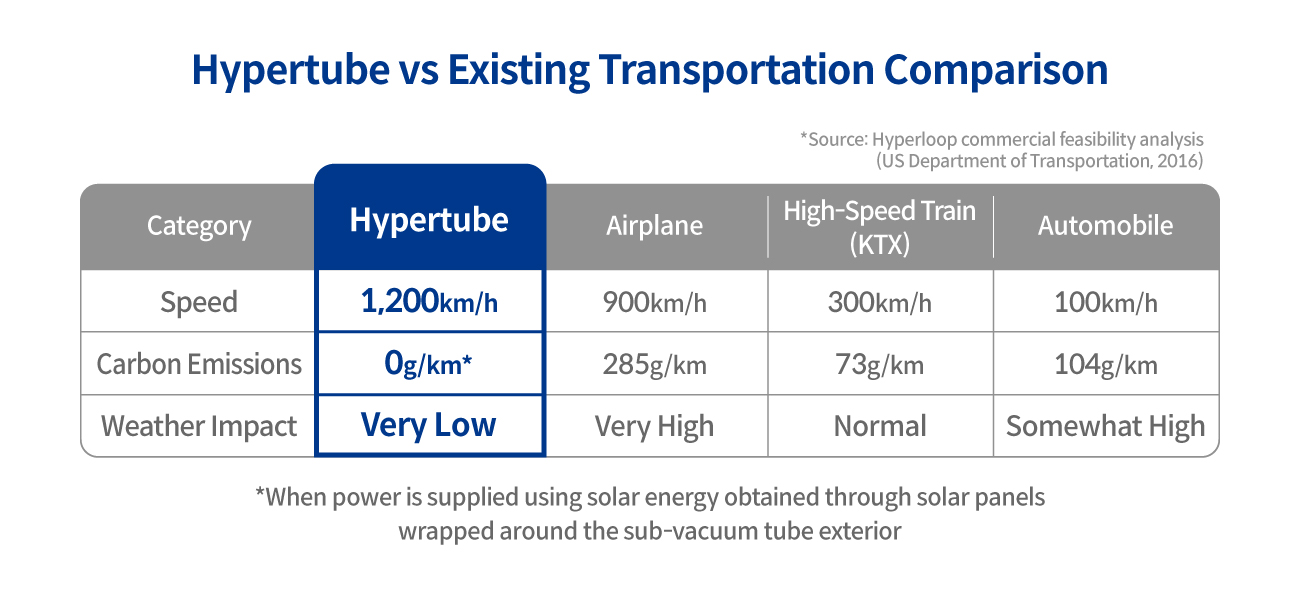

The fastest existing means of transportation is the airplane. It can travel to the opposite side of the earth within half a day because it rises to high altitudes and moves at a fast speed of about 900km/h. However, in the not-too-distant future, the title of ‘fastest means of transportation’ is expected to be claimed by the Hyperloop.

Hyperloop is a compound word combining hypersonic, which means supersonic, and loop, which means a circular ring. Here, loop refers to transportation systems such as trains that operate on a circular track (rails built in a ring shape). It is a futuristic ultra-high-speed transportation system where a train levitated by magnetic levitation technology in a near-vacuum (sub-vacuum) tube tunnel travels at near-sonic (subsonic) speeds through electromagnetic force. Internationally, it is commonly referred to as ‘Hyperloop’, whereas in Korea, it is known as ‘Hypertube’.

Experts predict that Hyperloop will be able to travel at a maximum speed of 1,200km/h. It is faster than both high-speed trains (300km/h range) and airplanes (900km/h range), theoretically allowing travel time from Seoul Station to Busan Station to be reduced to around 20 minutes.

Hyperloop is not just a transportation method that prioritizes speed alone. Being faster than other transportation modes, it offers more frequent operations per hour, lower maintenance costs due to operation in a vacuum tube, and the environmental advantage of zero direct carbon emissions during operation. Additionally, it has the advantage of being more convenient than airplanes as it is minimally affected by weather conditions and offers easy station accessibility.

Considering the projection that more than 70% of the world’s population will live in megacities (cities with populations over 10 million) by around 2050, Hyperloop, which connects major regions of the country within a one-hour living zone, can contribute to addressing regional extinction issues due to population decline and promoting balanced regional development.

According to projections presented by the Korea Railroad Research Institute at their 29th anniversary seminar held in February 2025, the total benefits from implementing Hyperloop amount to approximately 200 billion won annually, with regional economic ripple effects reaching 66.5 billion won annually. Looking at the global market, the potential market size of Hyperloop is estimated to encompass about 2,600 routes across more than 100 countries, with an annual global market size projected to reach 1.1 trillion dollars (approximately 1,540 trillion won).*

*Sources: Railway Economy ‘Hyperloop, “He who controls transportation controls the world” [Future Railway Technology]’, 12.17.2024

Elon Musk Ignited It, and the World Rushed into the Hyperloop Development Race

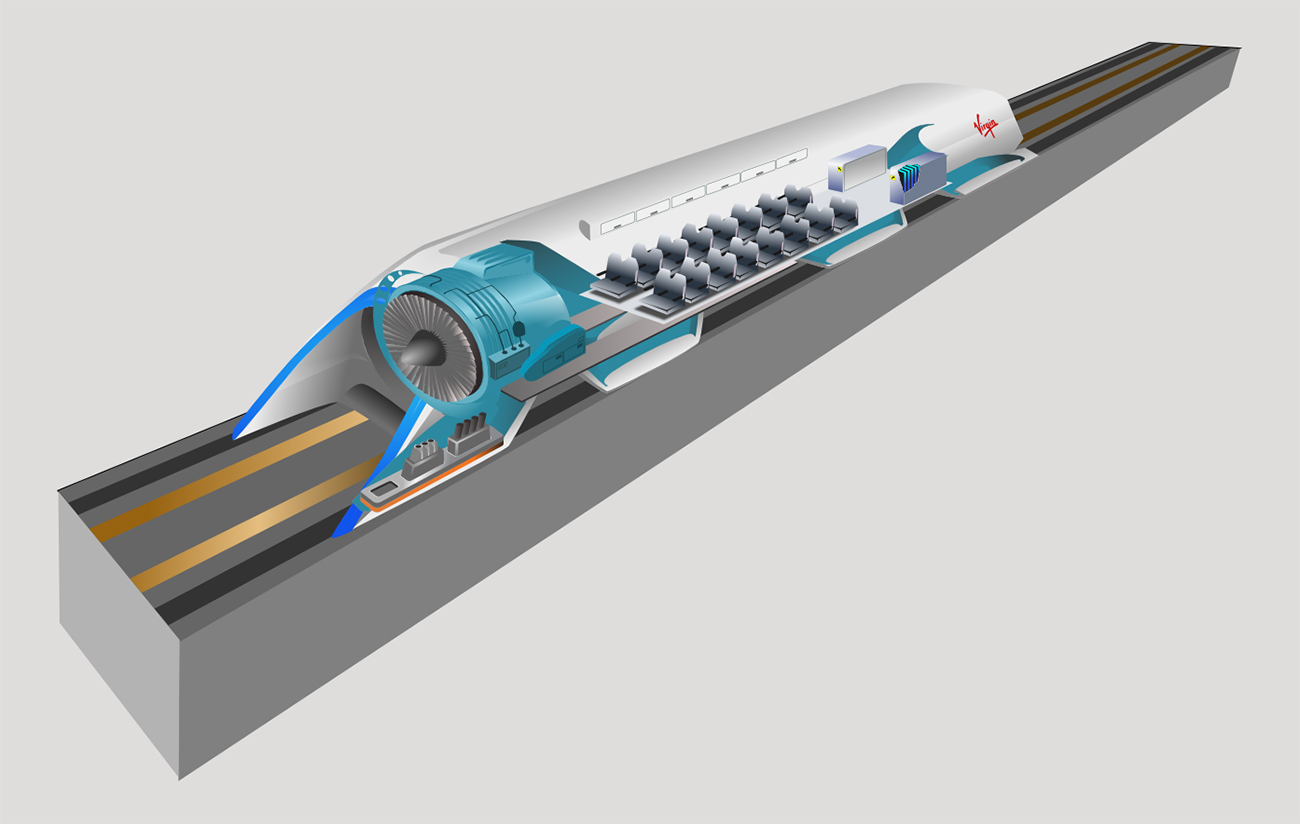

Research on high-speed transportation systems based on concepts such as maglev trains and vacuum tubes has been conducted for quite some time, but it became widely known to the public through Tesla founder Elon Musk in 2013. He proposed the idea of floating a 28-passenger sealed capsule inside a tube traveling at the speed of sound and named it ‘Hyperloop’. According to this concept, the San Francisco to Los Angeles route (about 613km), which takes 5 hours and 30 minutes by car and about 1 hour by plane, could be traversed in just 30 minutes with the Hyperloop.

Subsequently, ‘Virgin Hyperloop One’, backed by Richard Branson, chairman of the British Virgin Group, carried out related projects, and in 2017 successfully ran a full-scale experimental train carrying passengers at 384km/h over a 450m section. In 2020, it recorded 172km/h in a manned test with two passengers, but the project progressed slowly afterward and was suspended in 2023.

In Europe, a Hyperloop test center featuring a 420m-long Y-shaped track was constructed in Veendam, Netherlands, in 2024. The center was built by HARDT, a startup founded by a research team from Delft University of Technology, where maglev vehicle development is also underway. Around the same time in Germany, the Technical University of Munich developed a Hypertube prototype.

The ‘Korean Hyperloop’ Hypertube Technology Development Project that Pioneered the Research

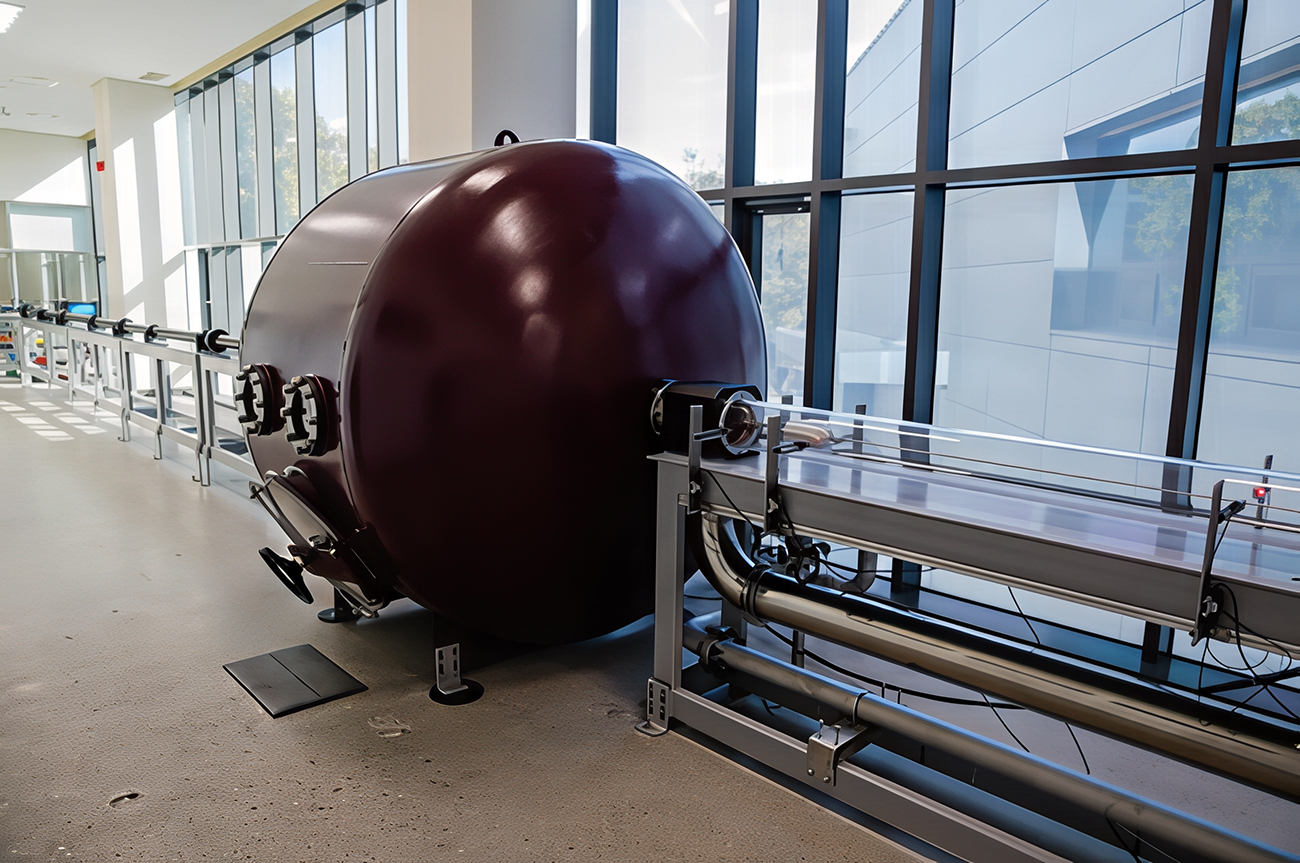

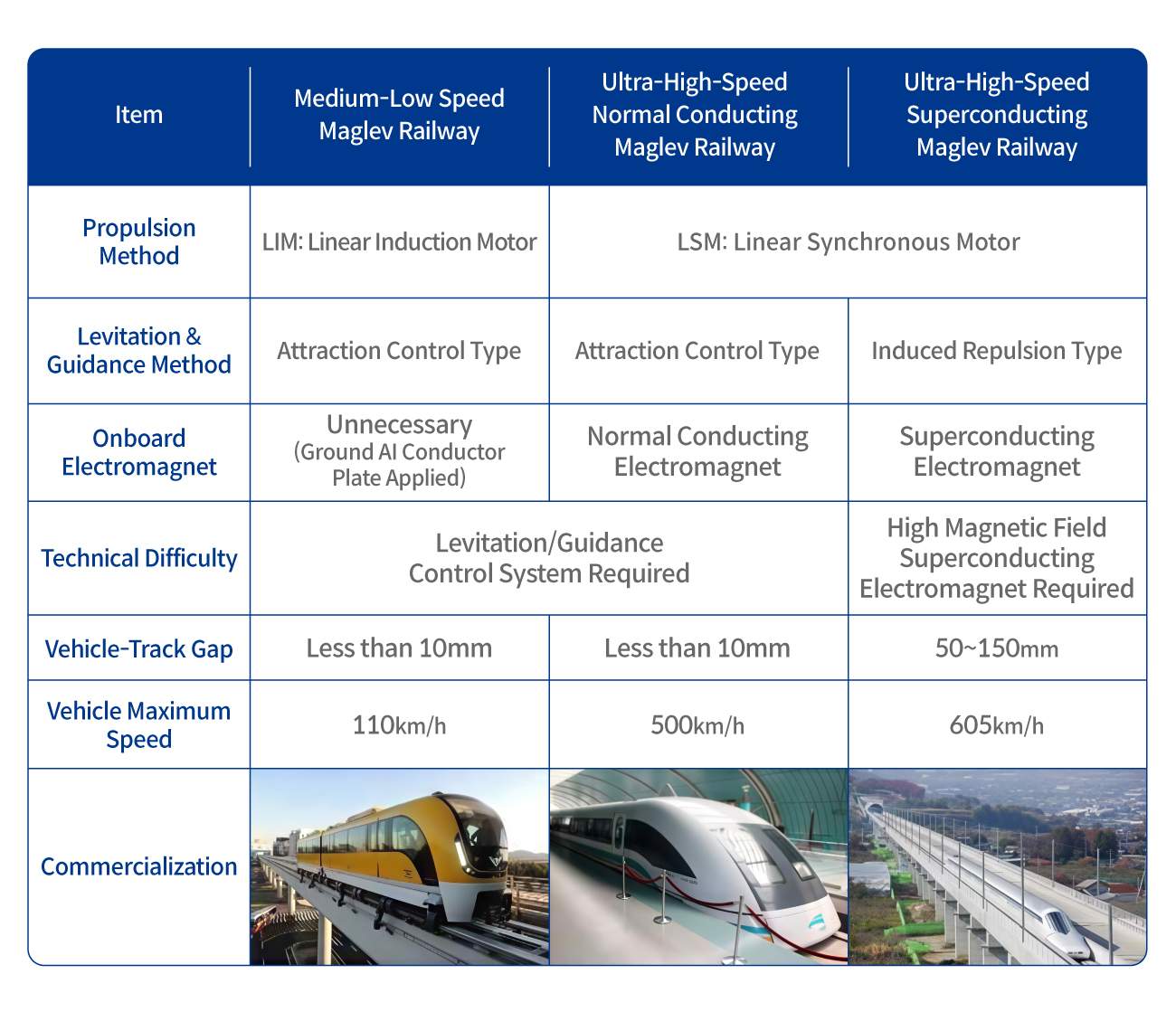

Korea had been conducting research on Hyperloop technology even before it became widely known to the public through Elon Musk. The Korea Railroad Research Institute (KRRI) began basic research on Hyperloop through the ‘Ultra-High-Speed Tube Railway Technology Development’ project from 2009 and succeeded in running a 1/52 scale vehicle at 700km/h in a low-pressure tube of 0.2 atmospheres. Through the ‘Ultra-High-Speed Magnetic Levitation Railway Technology Development’ project jointly conducted by KRRI and the Korea Institute of Machinery & Materials from 2011 to 2015, they developed a 550km/h-class maglev train prototype applying large-capacity linear synchronous motor propulsion technology and conducted tests on a 150m-long maglev test track built in Osong, Chungbuk.

From 2016 to 2024, the ‘Subsonic Capsule Train Core Technology Development’ project was carried out with support from the Ministry of Science and ICT. The subsonic capsule train refers to an ultra-high-speed capsule-type train that runs at speeds of around 1,000km/h, equivalent to 0.8 times the speed of sound, within a sub-vacuum tube.

Based on this research, KRRI succeeded in achieving a speed of 1,019km/h at 0.001 atmospheres using a 1/17 scale Hypertube test device in 2020. This is recognized as the world’s first demonstration of near-sonic speed travel for Hyperloop, and is considered to have laid the foundation for commercialization by securing the basic design and original technology of Hypertube. Having conducted research and development on core Hyperloop technologies from an early stage, Korea is considered to have reached world-class levels in vacuum tube technology, high-temperature superconducting-based magnetic levitation and propulsion technology, and ultra-high-speed driving stabilization technology. *

*sources: Railway Economy, ‘The Key Player in Creating a New Transportation Revolution, ‘Hyperloop’ [Future Railway Technology]’, 11.12.2024.

The South Korean government has been promoting related technology development projects under the name ‘Hypertube’ since including it in the ‘Smart Railway Transportation Technology’ sector of the 4th Basic Science and Technology Plan in 2018. Expectations grew as it was included in the 4th National Railway Network Construction Plan (2021-2030) in 2021 and among the government’s 120 national policy tasks in 2022. However, the project was temporarily delayed after failing the preliminary feasibility studies in both 2022 and 2023. In response, the Ministry of Land, Infrastructure and Transport revised its project direction to first focus on developing core Hypertube technologies such as superconducting magnetic levitation and linear propulsion systems, and then achieve commercialization in stages. By stages, they plan to complete core technology development from 2025 to 2030, and from 2028 to 2037, they will establish a Hypertube test track, conduct demonstration evaluations, and pursue practical technology development. Commercialization, including the establishment of a pilot route, is expected to be possible as early as 2038.

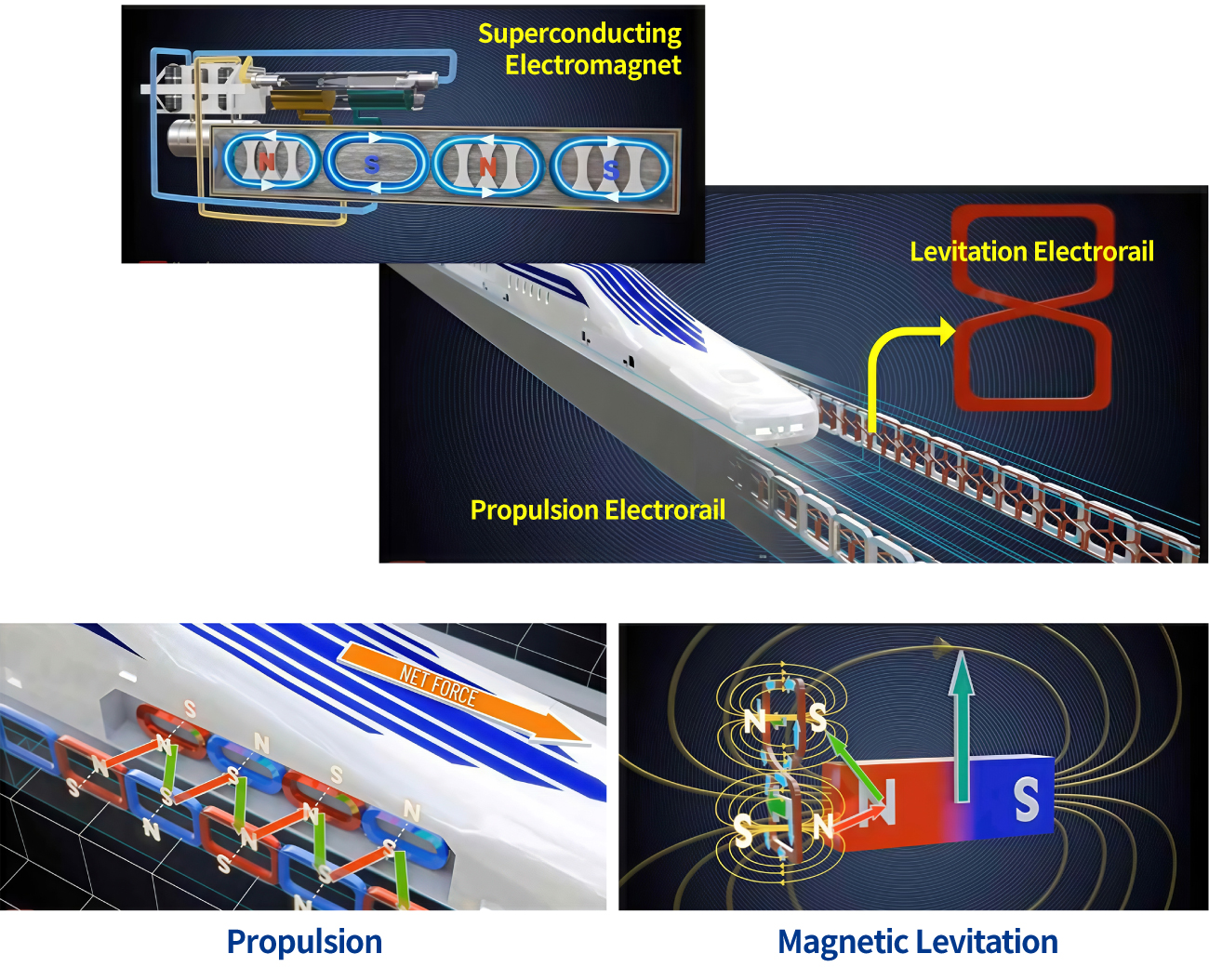

The Hypertube system promoted by the South Korean government basically follows a combination of linear synchronous motor and superconducting induced repulsion magnetic levitation methods. The propulsion force is generated from the magnetic fields pushing and pulling between the superconducting electromagnet mounted on the vehicle and the ground electrorail (armature), while propulsion is regulated by the synchronization of magnetic poles between the vehicle electromagnet and ground electrorail, along with sectional power supply control that provides propulsion power only to track sections occupied by the vehicle. The magnetic levitation principle follows the Electrodynamic Suspension (EDS) method, which maintains magnetic levitation and guidance at a height of about 100mm through the repulsive force between the induced magnetic fields generated by the vehicle electromagnet and the ground electrorail.

These magnetic levitation and propulsion technologies bring various advantages to the Hypertube system. First, the high thrust density is advantageous for ultra-high-speed operation, and the vehicle’s running stability is also enhanced during ultra-high-speed travel conditions. Another advantage is that no separate magnetic levitation or guidance control devices are needed thanks to the induced repulsion control technology. However, wheel operation similar to conventional railway vehicles is necessary until the train reaches a certain speed. From an infrastructure construction perspective, the relaxed precision requirements for track construction can also lead to construction cost reduction effects.

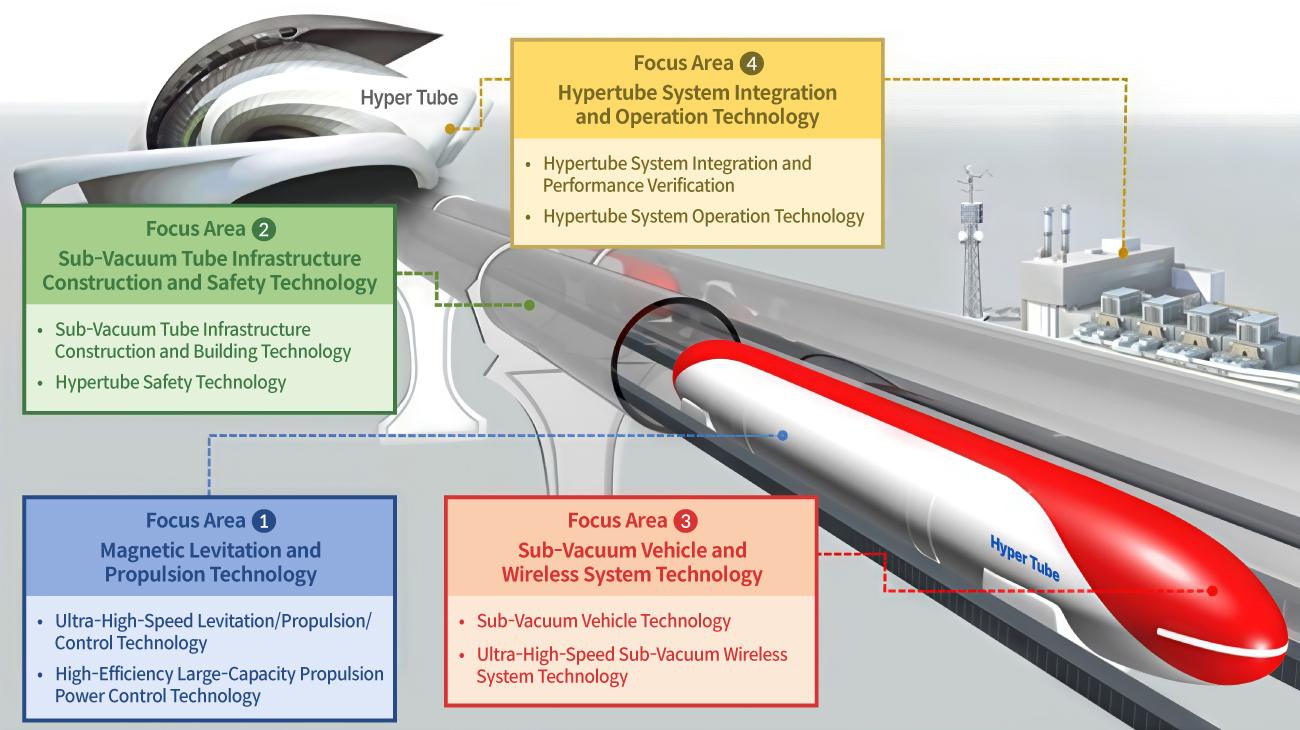

South Korea’s Ministry of Land, Infrastructure and Transport plans to first secure core technologies for Hypertube commercialization by investing 12.7 billion won over three years until 2027. Research and development aims to develop magnetic levitation and propulsion system technologies for implementing subsonic travel of vehicles and to verify sub-vacuum environment performance through actual operation tests of scaled-down vehicles on short-distance test tracks.

The detailed research and development tasks encompass four technologies: ① Linear electromagnetic propulsion guideway technology, ② Propulsion-levitation high-temperature superconducting electromagnet system development, ③ Ultra-high-speed linear propulsion control technology, and ④ Superconducting induced repulsion magnetic levitation technology. Each component technology can be compared to high-speed railway systems as: ① overhead catenary and track roadbed, ② vehicle engine, ③ onboard propulsion power (inverter), and ④ wheel-rail and running bogie.

Hyundai Rotem, at the Center of South Korea’s Future National Projects

Hyundai Rotem will participate as a joint research and development institution in this R&D project led by KRRI, taking charge of developing ‘Section Propulsion Controller’ and ‘Propulsion Power Energy Saver’ technologies within the ultra-high-speed linear propulsion control technology field. Ultra-high-speed linear propulsion control technology is a key component that controls the propulsion force and speed of subsonic traveling vehicles. According to the research and development schedule, design will be completed in the first year (2025), followed by production and component evaluation in the second year (2026), with testing and evaluation to be completed by the third year (2027).

The target is 20-25 passengers per car, with train operation intervals within 5 minutes. The expected transport capacity based on round-trip operation is a maximum of 2,000 people per hour.

The Ministry of Land, Infrastructure and Transport of South Korea launched the full-scale project beginning with the Next-Generation Railway System Hypertube Core Technology Development TF Kickoff Meeting held on April 9, 2025, under the Ministry’s supervision. The meeting was attended by representatives from the Ministry of Land, Infrastructure and Transport, Korea Agency for Infrastructure Technology Advancement, TF private committee members, and responsible persons from the main, joint, and commissioned institutions of the project, where core technology research strategies were presented and free discussions were held. Subsequently, on April 11, a ‘Future Innovation Mobility Hypertube Policy Discussion’ was held at the National Assembly Member’s Office Building, presenting a blueprint stating ‘plans to operate a pilot route as early as 2038.’

Lee Won-sang, Head of Hyundai Rotem’s Rail Solution R&D Center, stated that he would strive to secure core technologies for Hypertube based on high-speed railway development experience.

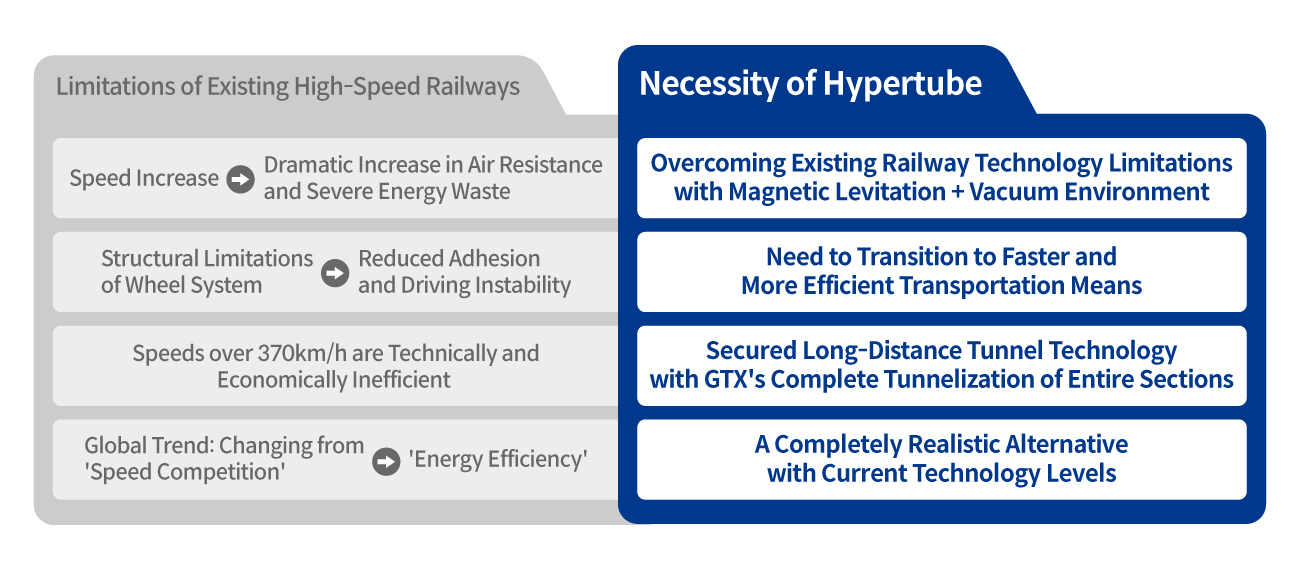

Hyundai Rotem also attended this policy discussion and presented the necessity of domestic introduction of Hypertube and the policy direction needed for successful commercialization. Lee Won-sang, Head of Hyundai Rotem’s Rail Solution R&D Center, who participated as a panel member in the discussion that day, explained, “In the case of existing high-speed railways, the higher the speed, the more air resistance increases dramatically, resulting in severe energy waste, and the global trend is also shifting from speed competition to energy efficiency-centered approaches.” Accordingly, he expressed the opinion that by utilizing magnetic levitation and vacuum environments, the limitations of existing railway technology can be overcome, and Hypertube development is necessary to transition to a faster and more efficient future transportation system.

In addition, Lee emphasized that Hypertube is a feasible alternative given the current level of Korean railway technology, stating, “Hyundai Rotem will continuously strive to secure core technologies for Hypertube based on the high-speed technology development experience accumulated so far.” He further emphasized, “To accelerate the commercialization of Hypertube, which has entered the stage of technical realization, it is necessary to promote pilot projects, system refinement, and demonstration projects, and national-level mid to long-term investment and strategy formulation are required.”

Hyundai Rotem is a world-class manufacturer of high-speed trains, having accumulated core technologies in high-speed train design and production over the past 30 years. The design and production know-how of high-speed trains that has been steadily built up—from the commercialization of the Korean high-speed train KTX-Sancheon, which began in 1997 and came to light in 2007; the production of the power-distributed high-speed vehicle KTX-Eum, which started with the development of HEMU-430X in 2007 and was completed in 2016; to the development of EMU-370 core technologies (propulsion, bogie, electrical system, etc.) that has been ongoing since 2021—is expected to be a great strength for the successful development and commercialization of Hypertube, a near-sonic ultra-high-speed transportation means.

In particular, due to the characteristics of GTX operating at depths below 40m underground, the entire section is being tunnelized, which is expected to be a significant contribution to the construction of Hypertube’s sub-vacuum tube infrastructure. Additionally, the GTX vehicles developed and supplied by Hyundai Rotem surpass KTX in propulsion force and stability due to the low air resistance in deep underground tunnels. One of the reasons why Hypertube trains can travel at near-sonic speeds can also be found in the near-vacuum environment and the resulting low air resistance. The fact that the recently opened GTX-A Paju-Dongtan line is responsible for the movement of more than 60,000 people per day, proving demand and business feasibility, has also been able to add momentum to the development of Hypertube.

Lee Won-sang, Head of the Rail Solution R&D Center, positively evaluated the feasibility of Hypertube at the National Assembly discussion site, saying, “Even with current metropolitan area railway (GTX) technology, we can create a perfect linear track from Seoul to Busan. Hypertube is by no means a distant future, and is expected to be the next model of GTX.”

Hyundai Rotem has led the 21st century Korean railway industry through innovative technology development and commercialization across all areas of railway, from railway vehicles to systems, O&M, and maintenance services. Now, through another innovation, the ‘dream train’ Hypertube, Hyundai Rotem will run toward a world of ‘another sustainable mobility’.