Korea’s railway technology is breaking through the 370 km/h barrier and ushering in a new chapter of the “ultra-high-speed era.” The Ministry of Land, Infrastructure and Transport recently announced that core technologies for the next-generation high-speed train EMU-370 have been successfully developed through a national R&D program.

The EMU-370 is a next-generation high-speed train that represents a step beyond the currently operating KTX-Cheongryong (EMU-320). In terms of commercial operating speed, it will be the world’s second-fastest high-speed train after China. Once commercialized, the EMU-370 is expected to significantly reduce travel times between major domestic cities, greatly enhancing convenience.

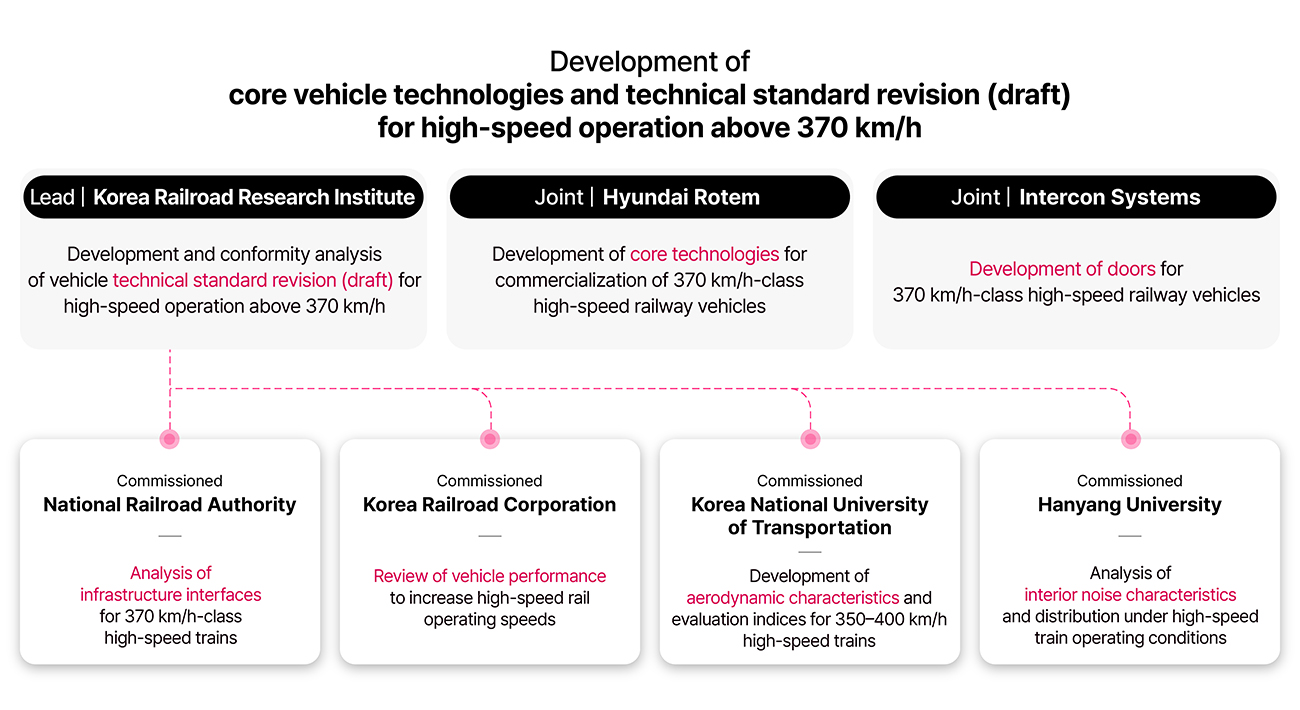

A total of seven organizations — including public institutions and private companies — participated in this project, with the Korea Railroad Research Institute serving as the lead organization. Hyundai Rotem contributed to the development of key rolling stock technologies, including aerodynamic shape optimization, high-output propulsion systems, and noise and vibration reduction technologies designed to maximize quietness. Building upon these advancements, Korea has secured a commanding technological edge to drive the global ultra-high-speed rail industry.

Korean High-speed Rail Technology Completed on the Foundation of Accumulated Experience

Hyundai Rotem’s high-speed train technology has evolved step by step — from the KTX-1 and KTX-Sancheon to the distributed traction high-speed trains KTX-Eum and KTX-Cheongryong. The design, manufacturing, and operational experience accumulated throughout this process has consistently strengthened the competitiveness of Korea’s homegrown high-speed rail technology.

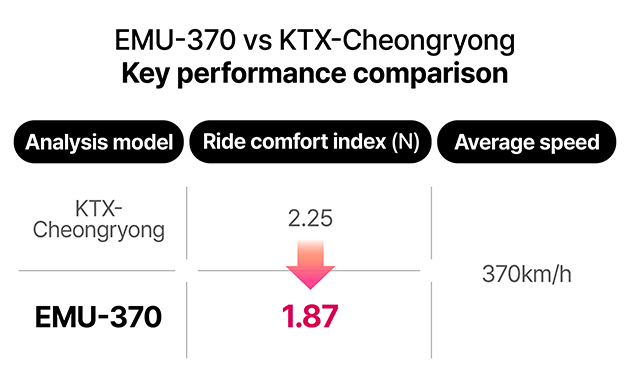

Specifically, the design and testing expertise in the ultra-high-speed domain secured through the development of the 430 km/h-class high-speed test train HEMU-430X served as the technological foundation for the development of the 370 km/h-class next-generation high-speed train EMU-370. The EMU-370 is the successor to the existing 320 km/h-class KTX-Cheongryong, targeting a maximum operating speed of 370 km/h and a maximum design speed of 407 km/h. Beyond simply increasing speed, the primary goal of this development was to realize a commercially viable ultra-high-speed train that simultaneously satisfies safety, quietness, and ride comfort under extreme high-speed operating conditions.

Aerodynamic Design Optimized for Ultra-High-Speed Operation

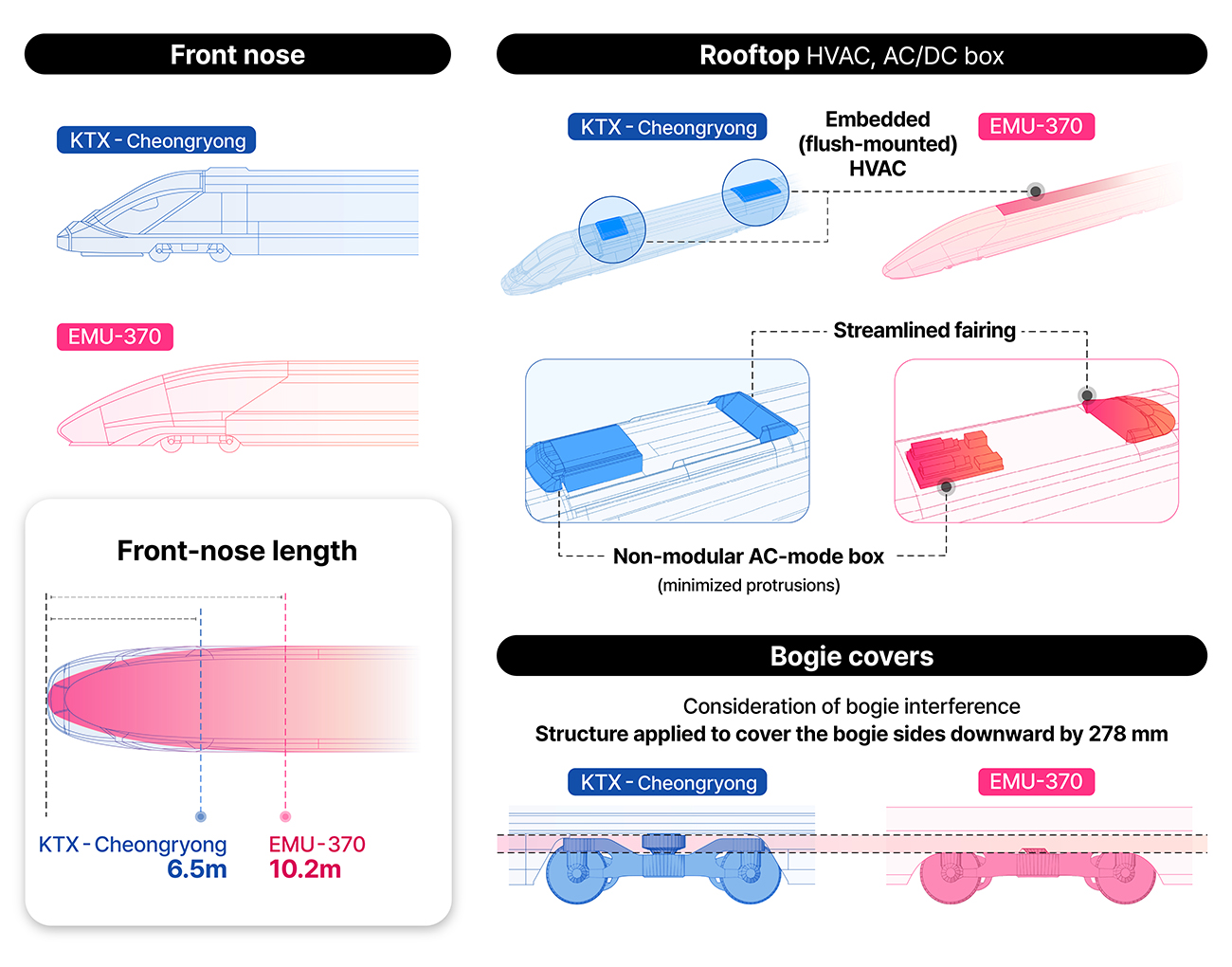

In an ultra-high-speed operating environment reaching 370 km/h, aerodynamic drag accounts for an overwhelming proportion of total running energy consumption. To overcome this, Hyundai Rotem adopted a highly sophisticated approach to the overall vehicle shape design. Compared to the existing KTX-Cheongryong, the EMU-370 extends the nose length by approximately 3.7 meters (with the trainset length increased by 1,000 mm) and adopts a recessed HVAC system to streamline airflow over the roof. In addition, the extensive use of bogie cover structures effectively suppresses aerodynamic drag in the underbody area.

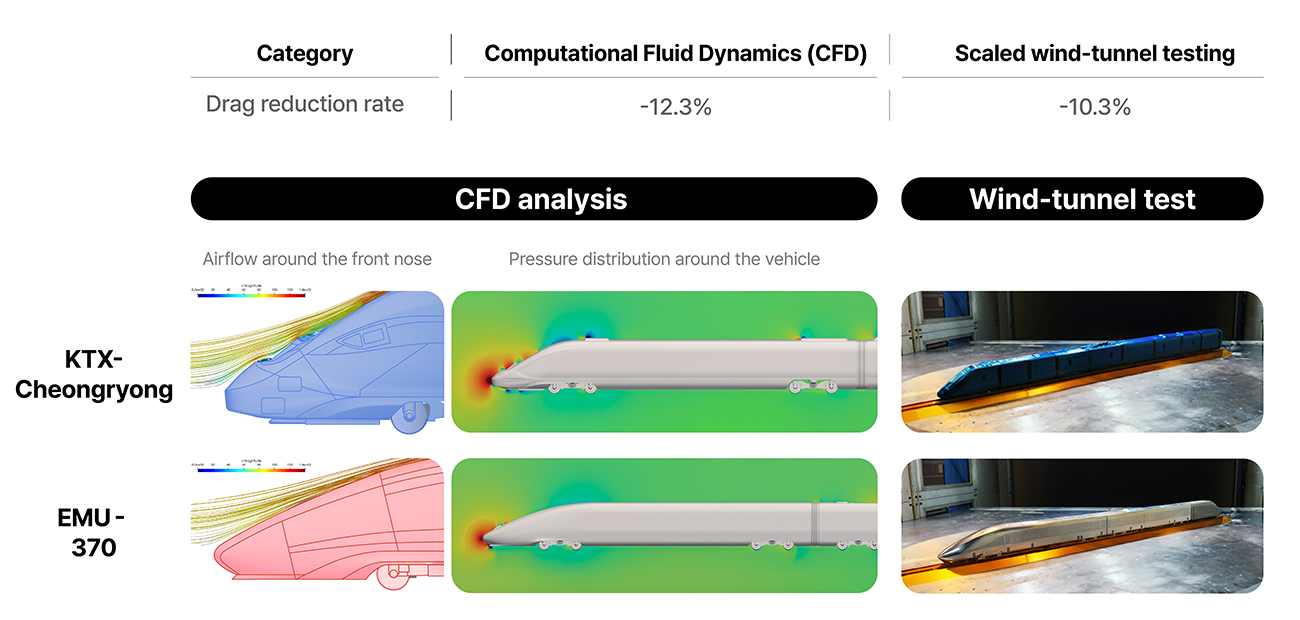

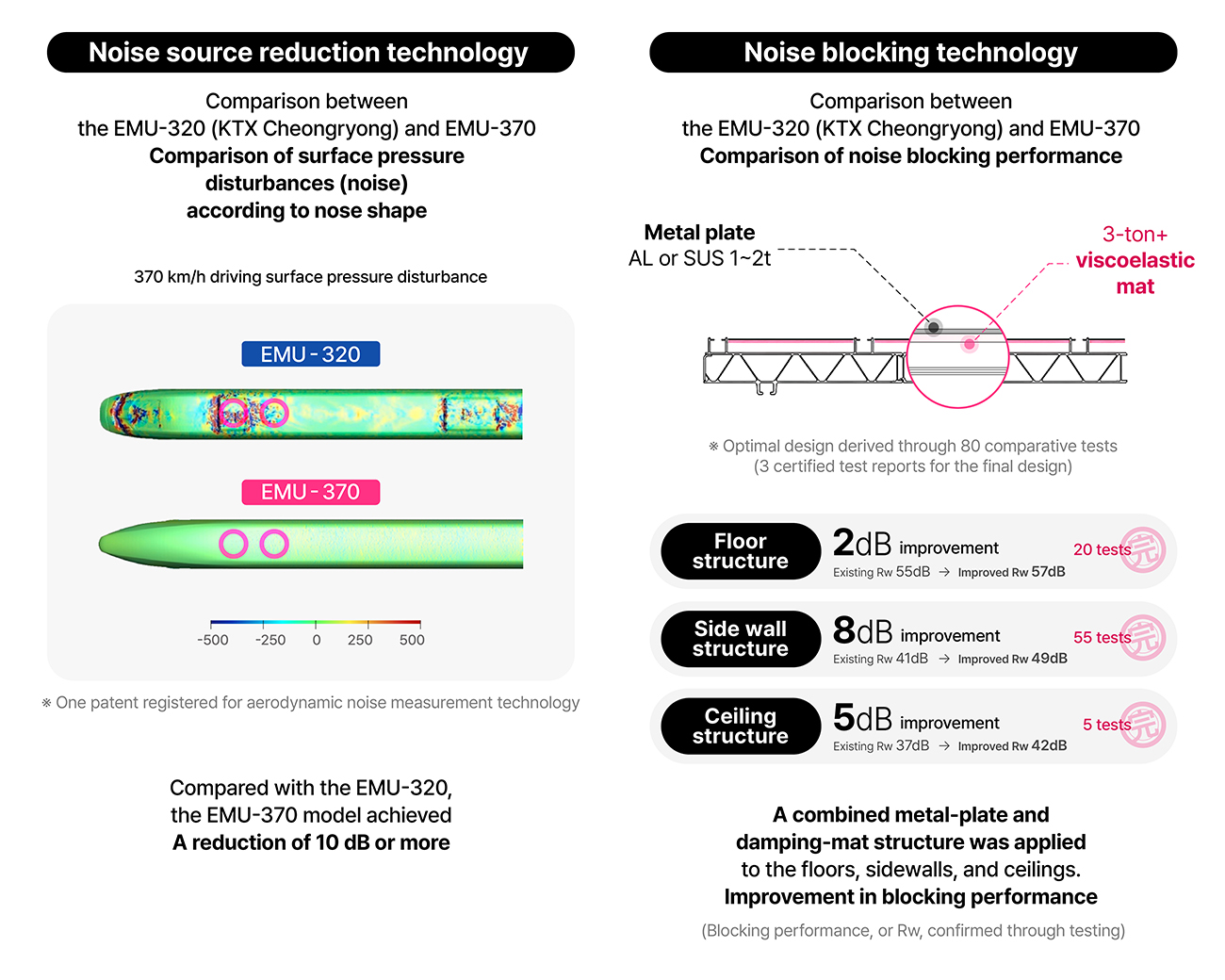

These aerodynamic designs were scientifically validated through Computational Fluid Dynamics (CFD) analysis and scaled wind-tunnel testing. As a result, they achieved a reduction in aerodynamic drag of approximately 10% or more. This not only improves energy efficiency, but it also serves as a core technology for reducing aerodynamic noise generated at high speeds and for realizing a quieter interior environment.

High-output traction motor design premised on ultra-high-speed operation

The propulsion system of the EMU-370 was also newly designed with ultra-high-speed operation at 370 km/h in mind. Hyundai Rotem advanced the entire motor and power-conversion system to secure both the required output and stability in the high-speed regime.

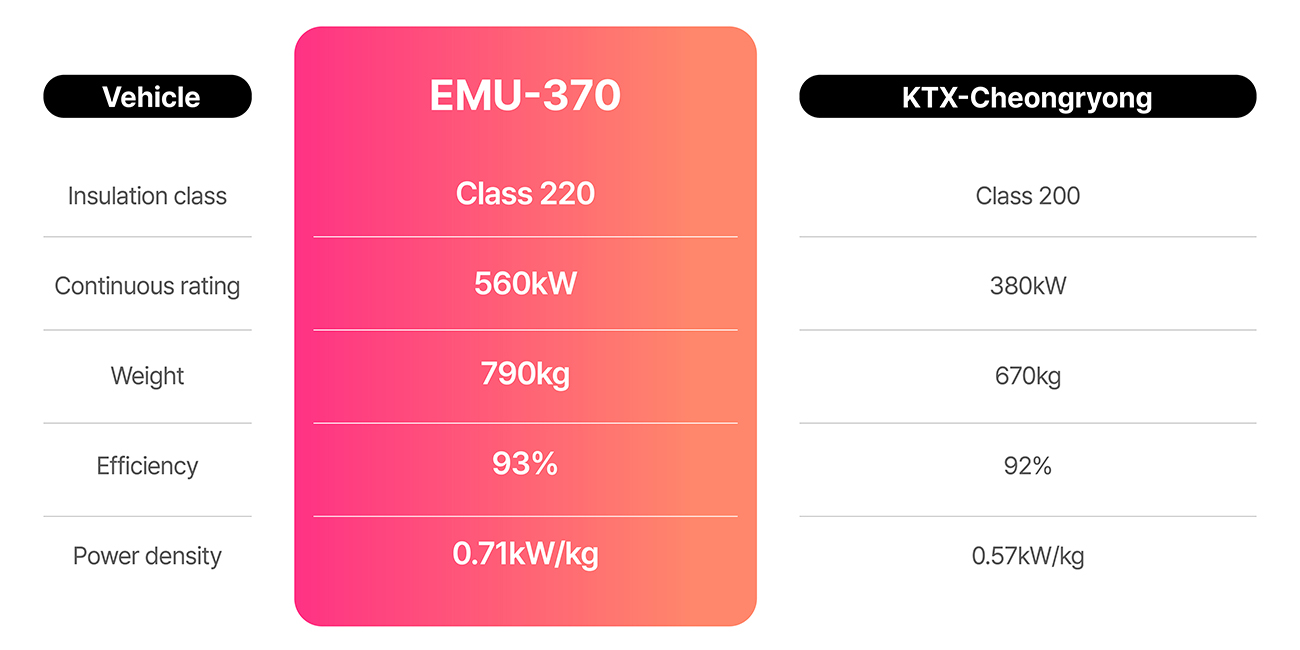

The EMU-370 is equipped with a high-output traction motor of 560 kW class, significantly increasing power density compared to the existing KTX‑Cheongryong (380 kW). The main converter capacity was also boosted to 2,800 kVA, ensuring stable traction performance even in the ultra-high-speed range.

The traction motor achieved both miniaturization and high output through an optimized design based on electromagnetic analysis for heat-loss evaluation and thermo-fluid analysis for cooling-structure improvement. With prototype manufacturing and type testing finished, the technology has already entered the verification stage for application to actual rolling stock.

Integration of noise and vibration reduction technologies

Achieving interior quietness at operating speeds of 370 km/h is widely regarded as a formidable technical hurdle in high-speed rail engineering. To address this, Hyundai Rotem conducted integrated R&D on noise-source reduction, sound-insulation technologies, and analytical methods, targeting a reduction of interior noise by 2 dBA compared with existing high-speed trains — maintaining interior noise at 73 dB(A) or below during 370 km/h operation using the manufactured traction-motor prototype.

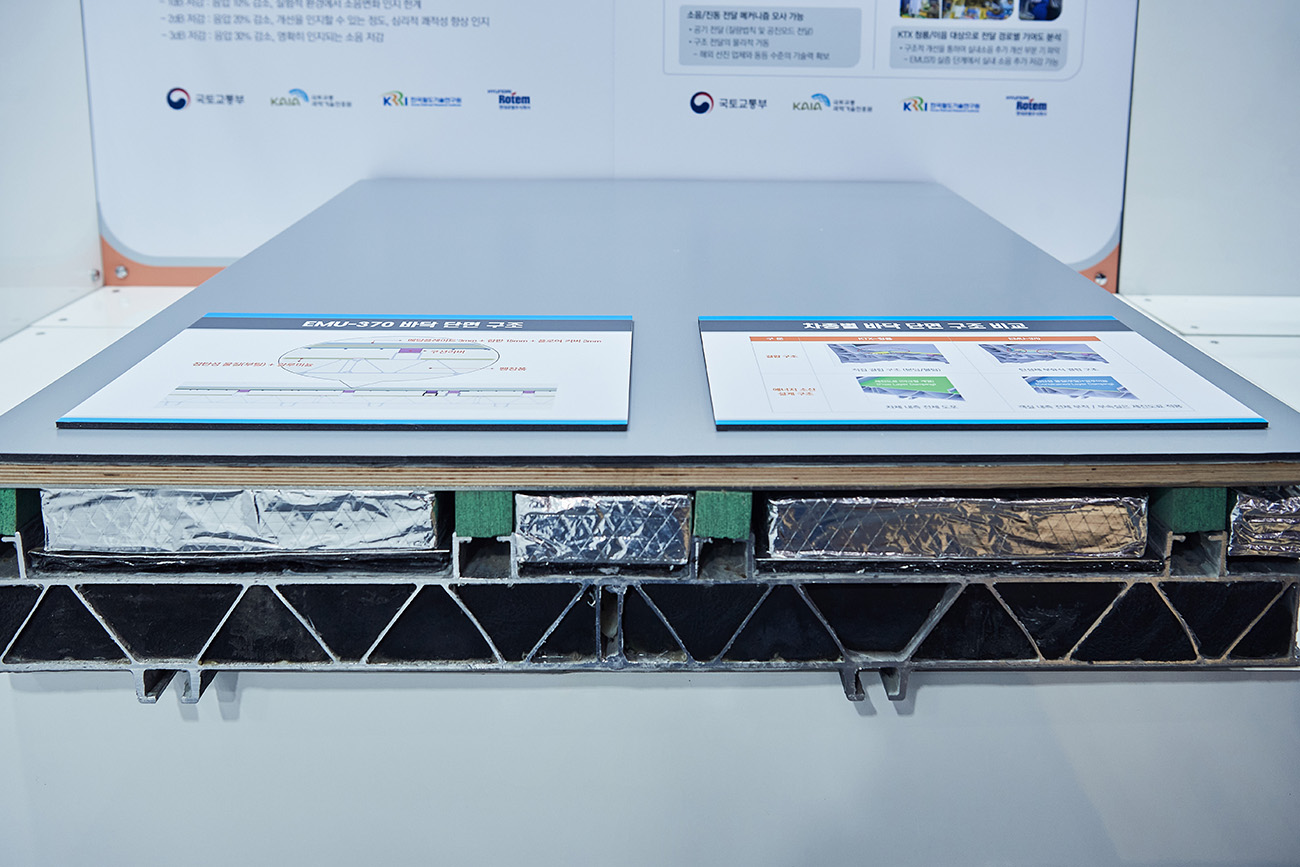

Another notable point is the combined application of aerodynamic noise reduction through improved nose shape, metal plate-viscoelastic mat composite structures applied to the floors, sidewalls, and ceilings, and vibration reduction design based on transmission path analysis.

In addition, by applying NVH (Noise, Vibration, Harshness) analysis techniques accumulated in the automotive sector to railway vehicles, core technological assets have been secured for future high-speed train development.

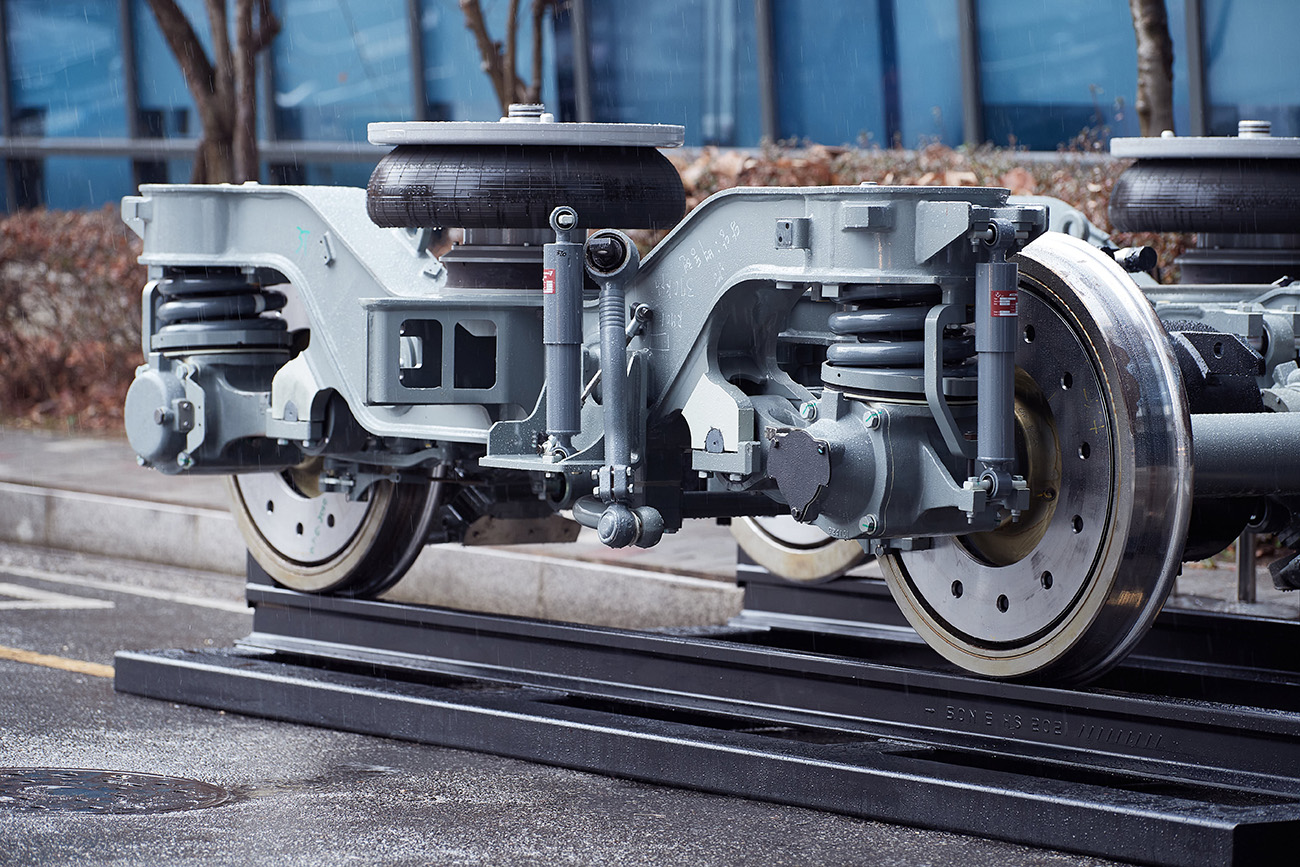

A core element supporting high-speed stability: the 370 km/h-class high-speed bogie

The high-speed bogie is a core component that determines running safety and ride comfort in ultra-high-speed trains. Through analyses that consider ultra-high-speed operating conditions, Hyundai Rotem derived optimized suspension characteristics, securing stable and smooth ride comfort with a ride comfort index (N) of 2.0 or less even at 370 km/h.

The manufactured bogie has completed step-by-step component tests and assembly verification, and has now finished roller rig testing. Hyundai Rotem is systematically carrying out technical verification for real-vehicle application, focusing on securing stable running behavior even under ultra-high-speed conditions.

Advanced airtightness and sound insulation performance for ultra-high-speed operation

At operating speeds of 370 km/h, rapid pressure changes occurring during tunnel entry and exit place direct stress on door airtightness performance. To respond to this ultra-high-speed environment, Hyundai Rotem plans to enhance technological self-reliance in core components for the EMU-370 by developing high-speed railway airtight doors with domestic technology, which previously relied heavily overseas suppliers.

Beyond Speed, Speaking Through Technological Maturity

The development of a 370 km/h-class ultra-high-speed train is more than just a speed competition. Hyundai Rotem has steadily accumulated a high level of technological maturity with commercialization in mind by organically integrating technologies across the entire vehicle domain — from aerodynamics and propulsion systems to noise and vibration, high-speed bogies, and airtight doors. This demonstrates that Korea’s domestic high-speed rail has progressed beyond the stages of testing and demonstration, and has entered a technological framework capable of competing in the wider global ultra-high-speed rail market. Rather than a simple aggregation of individual technologies, the EMU-370 embodies integrated system capabilities that can be verified under real operating conditions.

This technological leap toward 370 km/h represents the culmination of Hyundai Rotem’s long preparation for the era of commercial ultra-high-speed rail. It is a clear signal that Korean railway technology is advancing to the next stage