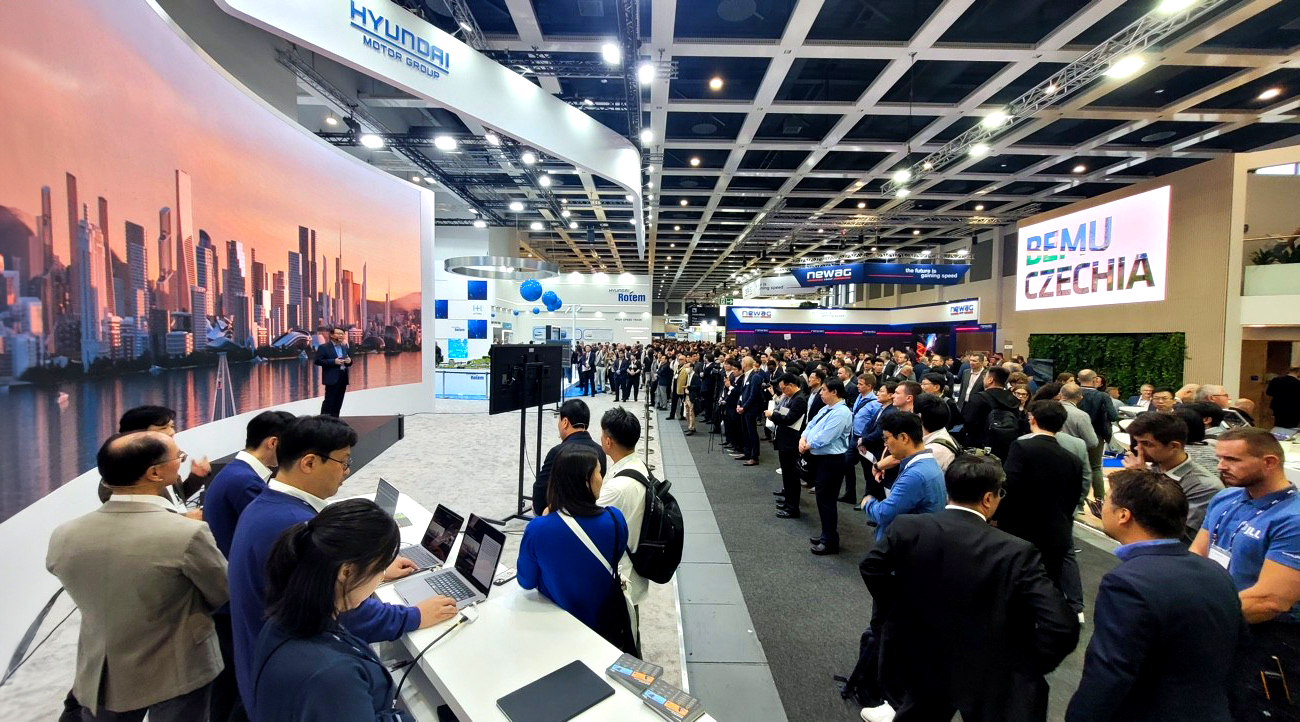

Hyundai Rotem participated in the “14th Berlin International Trade Fair for Transport Technology 2024 (InnoTrans 2024)” held from September 24 to 27 (local time) at the ExpoCenter City in Berlin, Germany, where they unveiled their vision for hydrogen mobility and high-speed railway technology.

Now in its 14th edition, InnoTrans is the world’s largest trade fair for transport technology, first held in 1996 and conducted biennially. In 2024, more than 2,940 companies from 59 countries, including global rail manufacturers such as Siemens and Alstom, participated, showcasing a variety of innovative railway technologies focused on digitalization and sustainability.

Hyundai Rotem, a regular participant in this event since 2004, attended this year’s exhibition led by Won-sang Lee, Executive Vice President of the Rail Solution Research Center, under the theme ‘H (representing Hydrogen Energy, H2 + High-Speed, H), Taking you forward the next.’ The presentation highlighted several key aspects: ▲ Hyundai Rotem’s comprehensive solution capabilities for the entire hydrogen supply chain, from production to usage. ▲A roadmap for hydrogen mobility, starting with hydrogen fuel cell trams. ▲ The past, present, and future of domestic high-speed trains, as well as the recently opened Deep Underground Metropolitan Railway System (GTX).

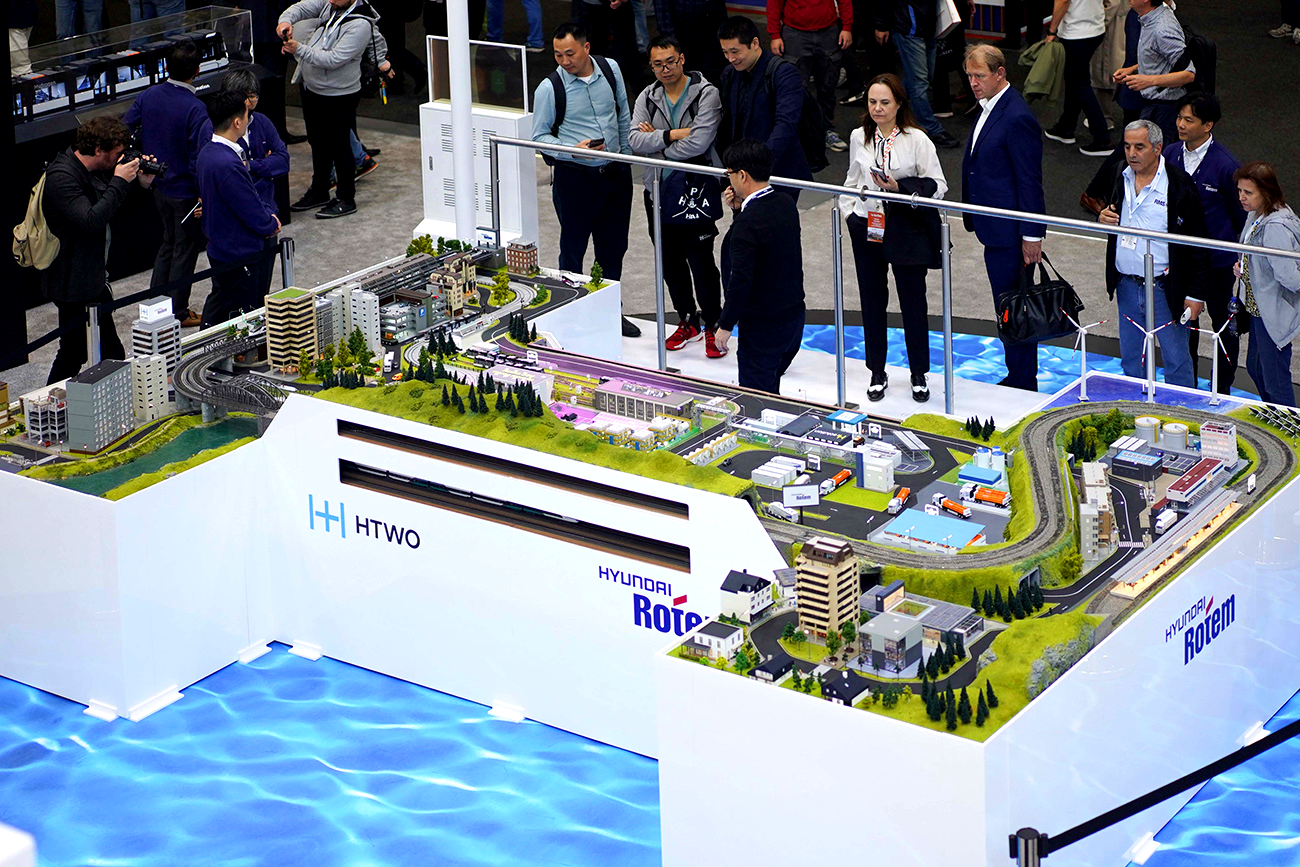

Hyundai Rotem’s exhibition featured a diorama representing the forthcoming hydrogen society. This model showcased hydrogen-electric trams and hydrogen-powered locomotives operating in urban environments, while hydrogen production, storage and transportation were managed by Hyundai Rotem’s equipment, including hydrogen extractors and charging stations.

In the outdoor exhibition area, Hyundai Rotem showcased a full-scale hydrogen-electric tram, allowing visitors to observe both the interior and exterior of the vehicle. This tram, equipped with Hyundai Motor’s hydrogen fuel cell system, is a catenary-free model capable of long-distance operation on a single charge. In July, Hyundai Rotem secured a contract with Daejeon City to supply hydrogen-electric trams, laying the foundation for their commercialization.

Furthermore, Hyundai Rotem presented its extensive lineup of high-speed trains, which have been developed over the past 30 years. This includes the KTX-Sancheon, a concentrated power vehicle successfully developed in 2008, the KTX-Cheongryong, a distributed power vehicle introduced later and the next-generation distributed power vehicle, the EMU-370, which is currently under development.

At the exhibition, Hyundai Rotem collaborated with the National Railroad Corporation to set up a “K-Rail Pavilion,” where they introduced the recently launched metropolitan express railway (GTX) in South Korea. The GTX, designed and constructed using deep tunneling methods throughout its entire route, is a new transportation system not found overseas.

Won-sang Lee, Executive Vice President of Hyundai Rotem’s Rail Solution Research Institute, stated, “Railroads have evolved to meet humanity’s growing demands for faster, more comfortable, rational and efficient travel. Through innovations in sustainable, rapid, and convenient railway technologies such as hydrogen mobility, high-speed trains and the GTX, we will strive to shape the future of the railway industry and improve the world for the better.”

“Total Solution Package:” Covering the Entire Hydrogen Value Chain from Hydrogen Production and Supply to Integration with Hydrogen Mobility

Hyundai Rotem began reviewing its hydrogen infrastructure business in 2018, recognizing that building hydrogen infrastructure and securing related technologies are key competitive advantages for the hydrogen mobility sector and the future energy industry. In 2020, leveraging Hyundai Motor’s hydrogen technology license, the company acquired the core technology for hydrogen reformers, which extract hydrogen from natural gas and officially entered the hydrogen infrastructure business.

Currently, Hyundai Rotem has established the “H2 Facility Assembly Center” at its Uiwang Research Center site, where it independently produces and supplies hydrogen reformer facilities. Furthermore, Hyundai Rotem is expanding its business scope to include on-site hydrogen refueling stations, where hydrogen can be produced and stored directly at the station, off-site refueling stations that store and sell externally-produced hydrogen and even mobile hydrogen refueling stations.

Based on this, the company plans to implement a “Total Solution Package” that takes full responsibility for the entire hydrogen supply chain, from direct hydrogen production and supply infrastructure to integrating hydrogen into mobility solutions.

Notably, Hyundai Rotem’s Total Solution Package is expected to create synergies with Hyundai Motor Group’s hydrogen value chain business brand “HTWO” and the comprehensive hydrogen solution “HTWO Grid,” which offers tailored packages optimized for various customer environments at every stage of the hydrogen value chain, including production, storage, transportation and utilization.

Hyundai Rotem is currently involved in hydrogen production and refueling projects at 23 locations across South Korea. The company is also preparing to participate in the supply of hydrogen-electric trams and hydrogen infrastructure packages for the hydrogen urban rail projects set to be introduced in Ulsan and Daejeon.

Based on the successful experience and proven technology of the Ulsan hydrogen-electric tram demonstration, Hyundai Rotem plans to expand into international markets. Many overseas operators have already expressed interest in purchasing Hyundai Rotem’s total solution packages for hydrogen-electric trams and hydrogen infrastructure.

Meanwhile, Hyundai Rotem continues to invest in research and development to address challenges related to the stability and economic viability of hydrogen supply, aiming for its widespread adoption. The company is also developing technologies such as carbon capture equipment, hydrogen burners, ammonia crackers, and water electrolysis systems to consider future environmental needs.

Hydrogen Mobility Roadmap: From Hydrogen Fuel Cell Trams to Hydrogen Trains, Multiple Units and High-Speed Trains

Hydrogen is an energy source that emits no pollutants other than water and causes no environmental harm, such as exhaust emissions, during its operation, making it the most eco-friendly energy source available. With a significantly higher energy density compared to conventional batteries, hydrogen is ideal as a large-capacity energy source, which is why it is gaining recognition as a powerful solution for the future of railway mobility.

Hyundai Rotem first developed a hydrogen fuel cell tram before rolling out full-scale hydrogen trains in its core Rail Solutions business. The hydrogen fuel cell tram is well-suited as an eco-friendly public transportation system for smooth travel in busy urban areas, as it combines ▲economic efficiency, ▲environmental friendliness and ▲convenience.

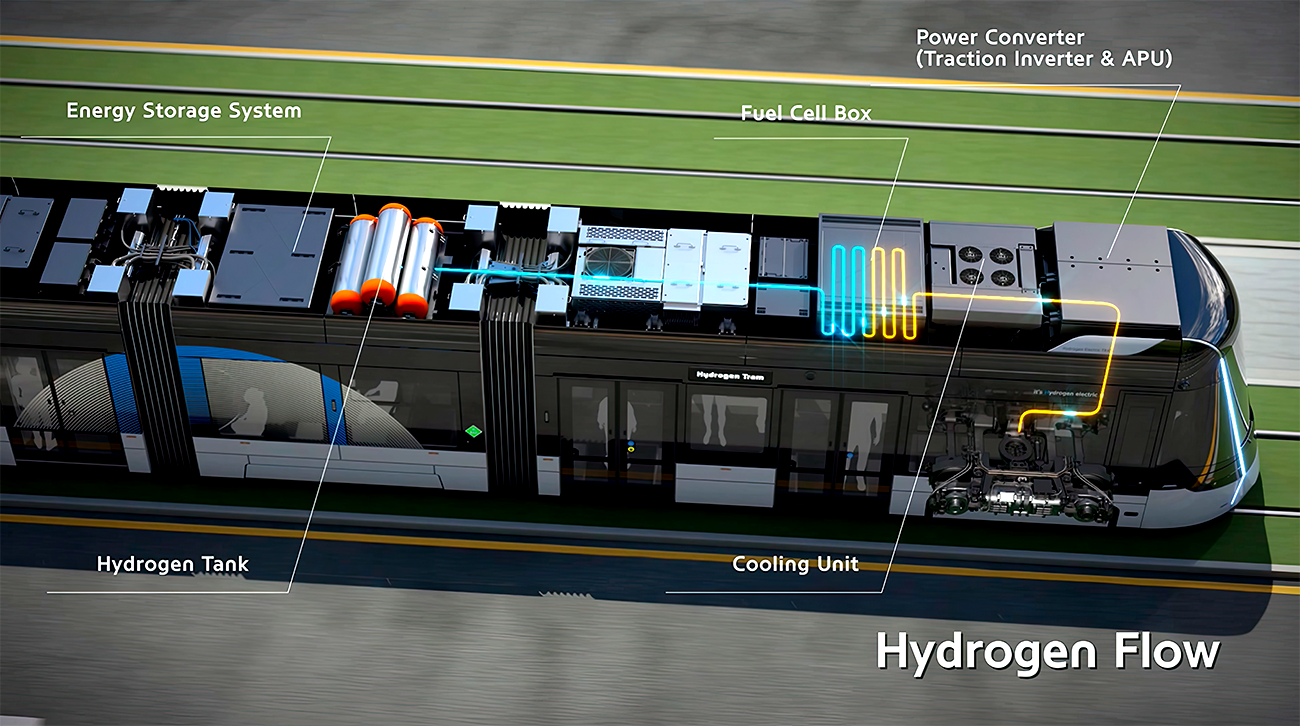

First, the hydrogen fuel cell tram uses a hydrogen fuel cell installed onboard, which generates electric energy directly through a chemical reaction between hydrogen and oxygen. The electricity produced by the hydrogen fuel cell is used to power the tram’s drive system, heating and cooling, while any surplus energy is stored in the Energy Storage System (ESS) battery. When the tram needs more power, such as during acceleration or from a standstill, it utilizes the energy stored in the battery. For cruising at a constant speed and deceleration, it operates using the energy generated by the hydrogen fuel cell, ensuring economic efficiency.

Hyundai Rotem’s hydrogen fuel cell tram is capable of long-distance travel, operating over 150 kilometers on a single charge, ensuring maximum efficiency in any urban transit environment. Another advantage is that it does not require additional electrical infrastructure, such as overhead lines or substations for power supply, which helps reduce the construction and maintenance costs of the power infrastructure.

Moreover, the hydrogen fuel cell tram purifies the surrounding air while operating, making it a superior eco-friendly mobility solution compared to traditional electric trams. The hydrogen fuel cell collects oxygen from the external environment to generate electrical energy, but if impurities are present in the collected oxygen, a complete chemical reaction cannot occur. The hydrogen fuel cell tram removes impurities through filters and humidifiers, releasing purified air back into the environment and helping purify fine dust and ultrafine dust in the air simply by operating it.

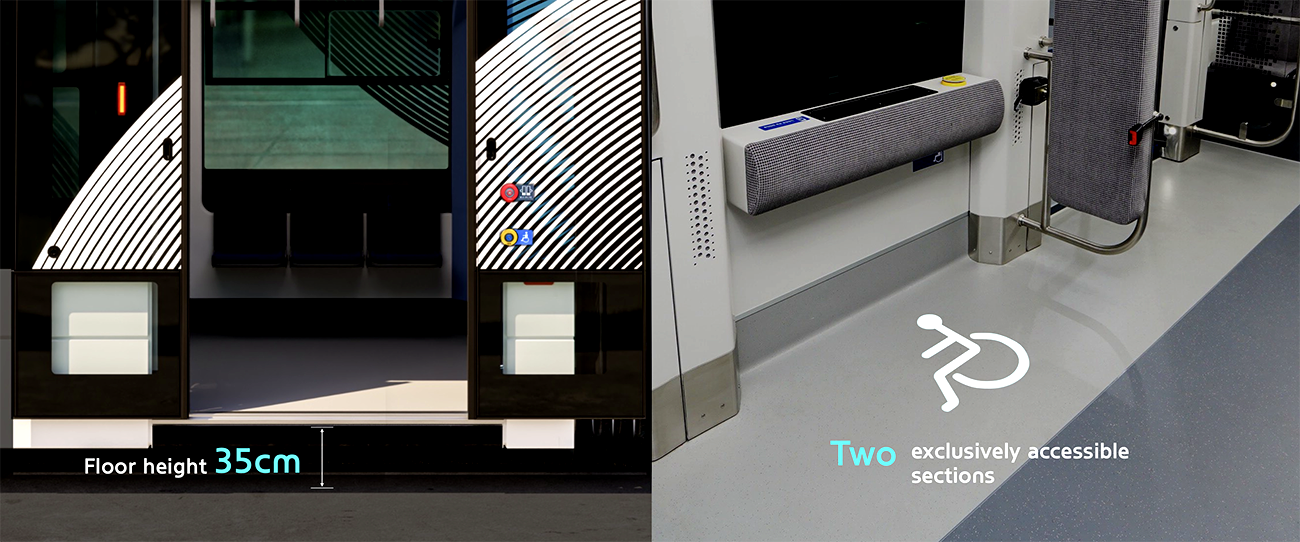

The Hyundai Rotem hydrogen fuel cell tram is meticulously designed, not only to ensure passenger convenience but also to incorporate safety features that comply with international safety standards. The floor height is 35 cm, lower than that of a standard bus and each car is equipped with two dedicated seats for passengers with reduced mobility, improving accessibility for both regular passengers and those with mobility challenges. Additionally, the tram features flooring that reduces noise and vibrations, double-leaf doors for easier boarding and disembarking and a spacious interior with a maximum height of 2.8 meters, providing a comfortable environment.

The tram’s design excellence has been recognized, winning the main award in the product category at the “2023 iF Design Awards,” one of the world’s top three design awards. This vehicle is characterized by its simple and luxurious exterior, designed to eliminate risk factors in the event of a collision. Notably, the front section is designed to push pedestrians outward in case of impact, reducing potential harm. The driver’s field of vision has been optimized to ensure clear recognition of pedestrians, especially children under 1 meter tall and the elderly. It also features LED daytime running lights (DRL), commonly used in passenger cars, enhancing both convenience and aesthetics.

Since November last year, the tram has successfully completed a 5,000-kilometer test run in Ulsan, meeting its performance goals and verifying its ride quality, vibration control and overall driving performance. In Korea, the hydrogen fuel cell tram will be introduced through the Daejeon Metro Line 2 and Ulsan Metro Line 1 projects.

Meanwhile, Hyundai Rotem’s hydrogen mobility roadmap, which began with the hydrogen fuel cell tram, is expected to expand to a wider range of hydrogen-powered trains. The world’s first hydrogen locomotive equipped with core technology based on liquid hydrogen is being prepared as a follow-up to the hydrogen fuel cell tram. Additionally, hydrogen multiple units, designed for long-distance operation with increased power and hydrogen capacity, are under development.

Hyundai Rotem plans to complete the development of a hydrogen locomotive capable of reaching speeds of up to 180 km/h by 2027 and introduce hydrogen locomotives and hydrogen high-speed trains with significantly extended operational range by 2030 through large-capacity fuel cell technology.

Showcasing Innovative Railway Vehicles: Independently Developed High-Speed Trains, Next-Generation High-Speed Train EMU-370, Deep Underground Metropolitan Railway System GTX, etc.

Hyundai Rotem is a global railway technology company that has been developing and producing railway vehicles for over 40 years, securing top-tier technological expertise and business capabilities. Notably, after quickly internalizing high-speed rail manufacturing technology initially transferred from abroad, the company has independently advanced key technologies for high-speed trains. It is the only domestic manufacturer that has developed various Korean high-speed trains such as KTX-Sancheon and SRT.

Hyundai Rotem began developing the next-generation high-speed train HEMU-430X in 2007 to actively meet diverse domestic and international high-speed train demands. This laid the foundation for the development of distributed-power high-speed trains, with technology enabling speeds over 420 km/h. Building on this foundation, Hyundai Rotem developed and mass-produced Korea’s first distributed-power high-speed train, the EMU-260 (KTX-Eum), which was deployed on major domestic routes starting in 2021. Three years later, it developed the EMU-320 (KTX-Cheongnyong), which increased the top speed to 320 km/h and was introduced into commercial service.

Currently, Hyundai Rotem is leading the development of core technologies for the high-speed train EMU-370 as part of a national R&D project. Thanks to meticulous research and engineering, the EMU-370 is a next-generation distributed-power high-speed train designed to provide passenger comfort and ensure safety and reliability, even at speeds of 370 km/h.

The EMU-370 features a vehicle design that reduces air resistance and minimizes aerodynamic noise as speed increases. By optimizing the front-end shape, embedding the HVAC system and redesigning the AC module box, Hyundai Rotem minimized roof protrusions to improve the airflow over the top of the vehicle. Additionally, side covers were applied in certain areas to improve airflow around the bogies. This resulted in about a 15% reduction in air resistance compared to the EMU-320. Furthermore, to minimize noise from external sources entering the interior, Hyundai Rotem optimized the cross-sectional profile of the body’s floor, ceiling and sidewall extrusion materials, significantly reducing noise levels.

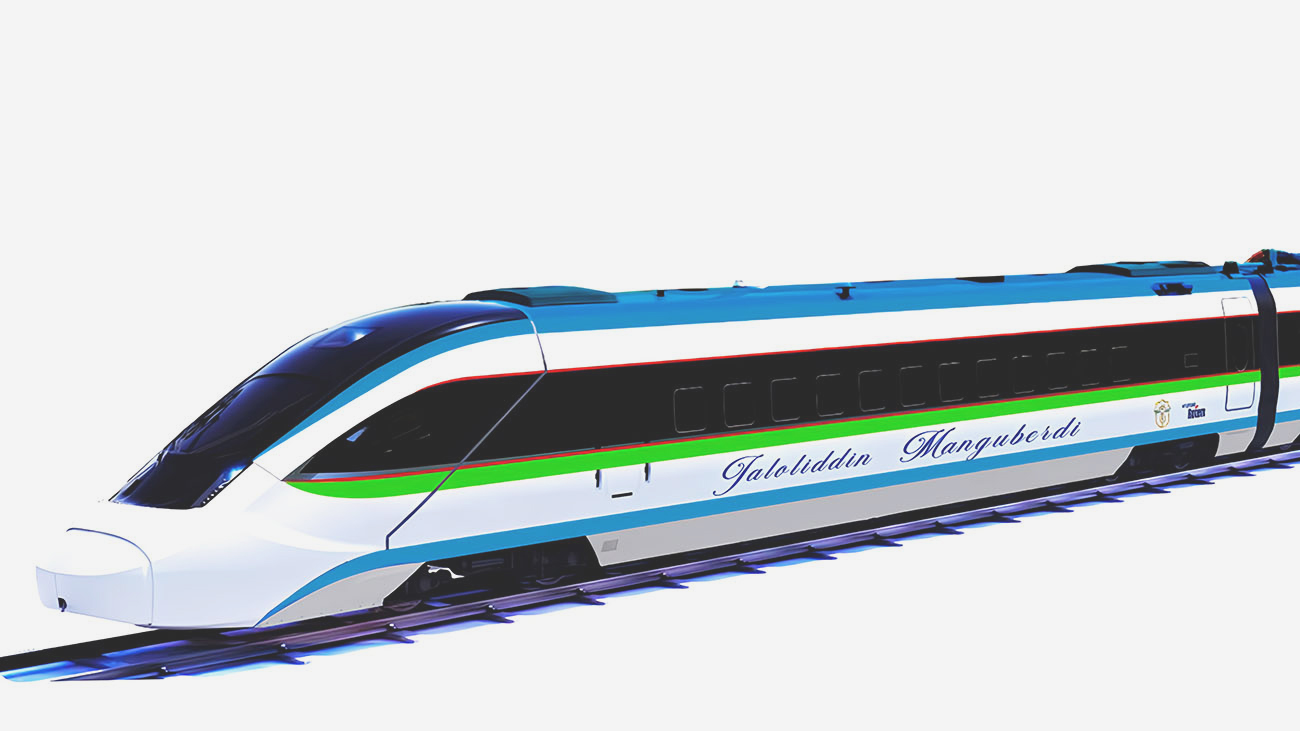

Building on the commercial success of the EMU-260 and EMU-320 distributed-power high-speed trains, Hyundai Rotem successfully exported 42 high-speed trains to Uzbekistan Railways this year. Marking the 20th anniversary of the KTX, this year also signifies the beginning of Korea’s high-speed train exports. Hyundai Rotem plans to accelerate its entry into overseas markets, starting with its first export order to the Eurasian continent.

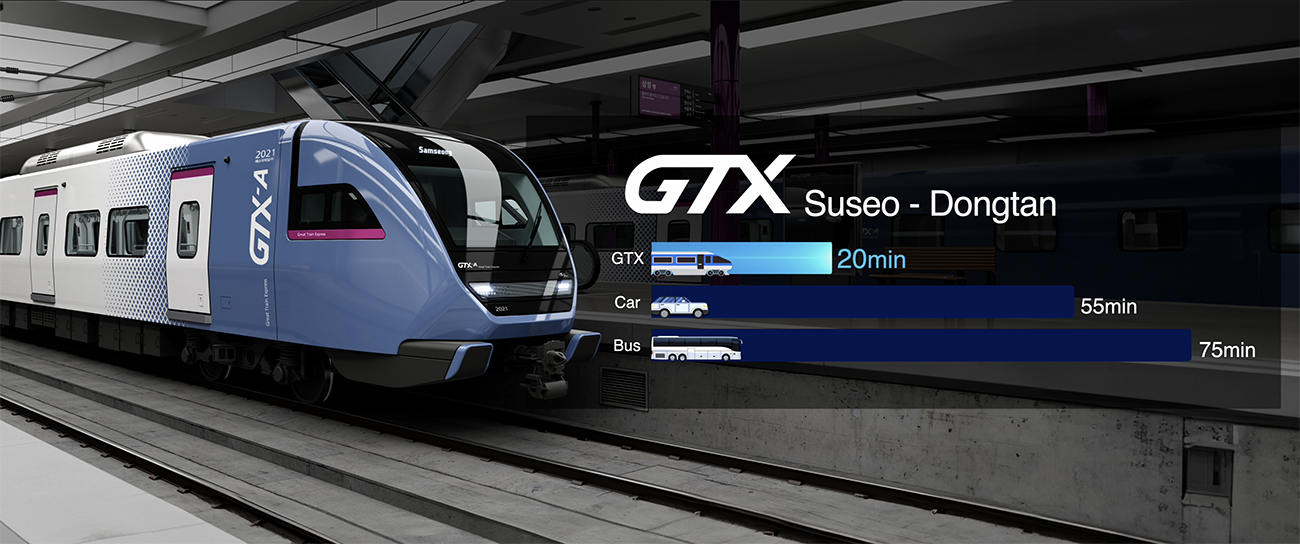

The Hyundai Rotem’s railway technology innovations extend beyond high-speed trains and are now transforming metropolitan transportation with the GTX system. GTX is a deep underground metropolitan railway system operating at 180 km/h, more than twice as fast as conventional subways, on tracks built 40 meters below ground.

As Korea’s first attempt at this new transportation system, GTX heralds a new era of metropolitan transit through a speed revolution. For example, on the GTX-A line, which partially opened this year, the travel time between Suseo and Dongtan is about 20 minutes. This is 55% shorter compared to driving (45 minutes) and 73% shorter compared to taking a bus (75 minutes). The GTX system is expected to revolutionize transportation infrastructure with easy integration and transfers to existing subway lines.

Various innovations have also been incorporated into the train itself. To create a more spacious and comfortable environment, the seat width has been expanded from 450mm to 480mm and seat-separating structures have been added between chairs to improve convenience and privacy. A large 37-inch display is installed above the doors and between seats, providing passengers with a wide range of visual information.

Additionally, air purification systems have been installed to ensure a comfortable indoor environment. The trains also feature plug-in doors rather than conventional sliding doors, which enhance soundproofing and airtightness. The doors of the GTX trains have been designed to be 1.6 meters wide, wider than those on standard subways, allowing passengers to board and disembark quickly and easily during peak commuting hours.

In addition, Hyundai Rotem has incorporated advanced railway technologies into the GTX system. These include an AI deep learning based facility monitoring system, condition based maintenance(CBM) technology enabling real-time monitoring of key components and high-voltage power system modularization.

Following the development of the trains for the GTX-A line, Hyundai Rotem plans to sequentially develop trains for the B, C, D, E, and F lines. This will contribute to a transportation revolution in the Seoul metropolitan area, aiming to reduce commuting times to within 30 minutes.