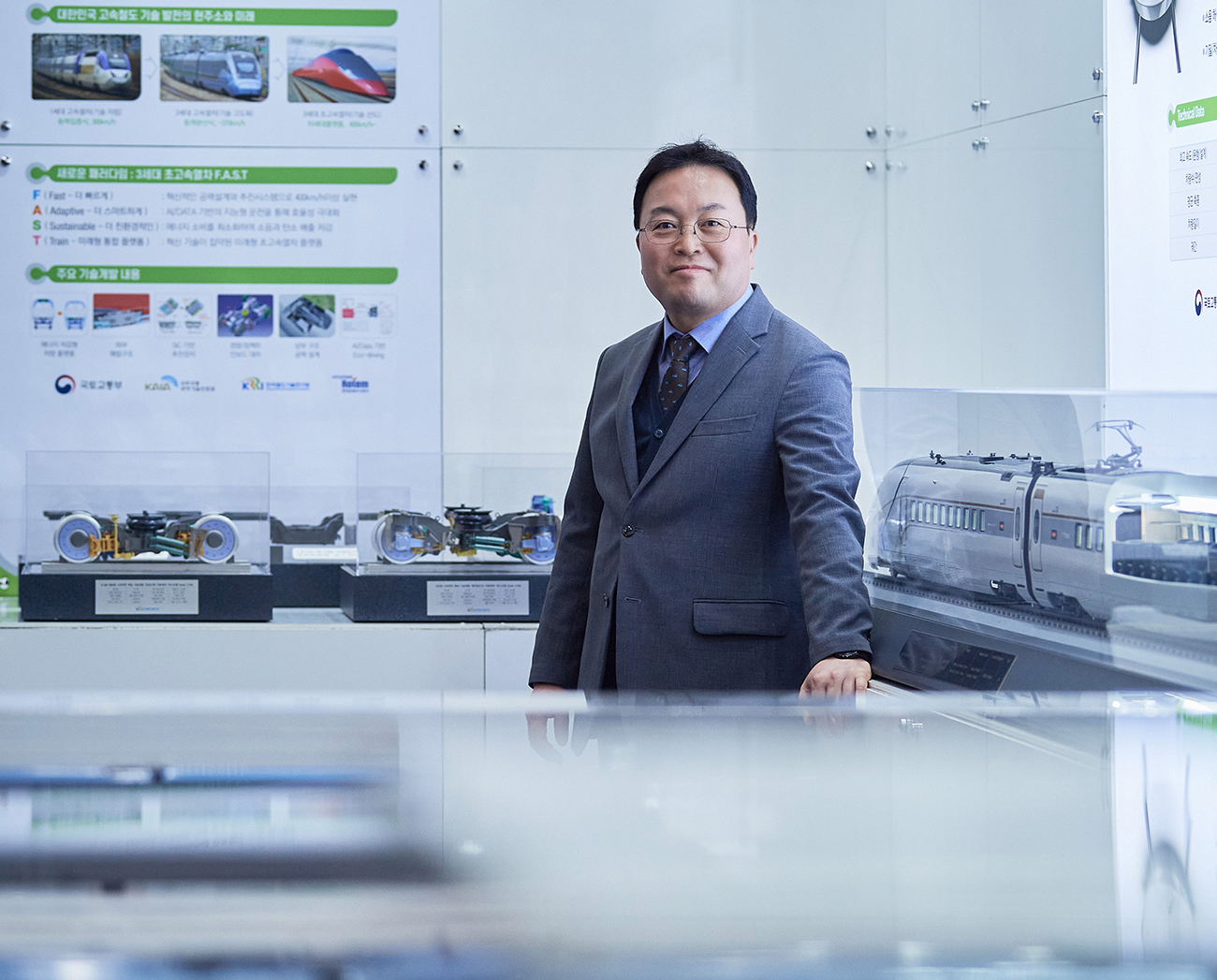

The success of the EMU-370 project means more than just adding another “fast train” to the lineup. From aerodynamic designs optimization that minimize air resistance to technical refinements that dramatically reduce noise and vibration experienced by passengers, this marks a signal that South Korean rolling stock technology has moved beyond mere “catching up” to the stage of “mastery.” At the heart of this massive project is Vice President Kong Myong-sang, who has been leading the high-speed train project leading the high-speed train development efforts.

At the new model’s achievement presentation, Mr. Kong said, “It is now time to move beyond the accumulation stage and advance toward stable, error-free technology,” setting a new standard for K-high-speed trains. At the presentation of the EMU-370’s research outcomes, we met with Mr. Kong to hear the intense behind-the-scenes story of the four-year development process and his vision for the next-generation roadmap in the global rolling stock market.

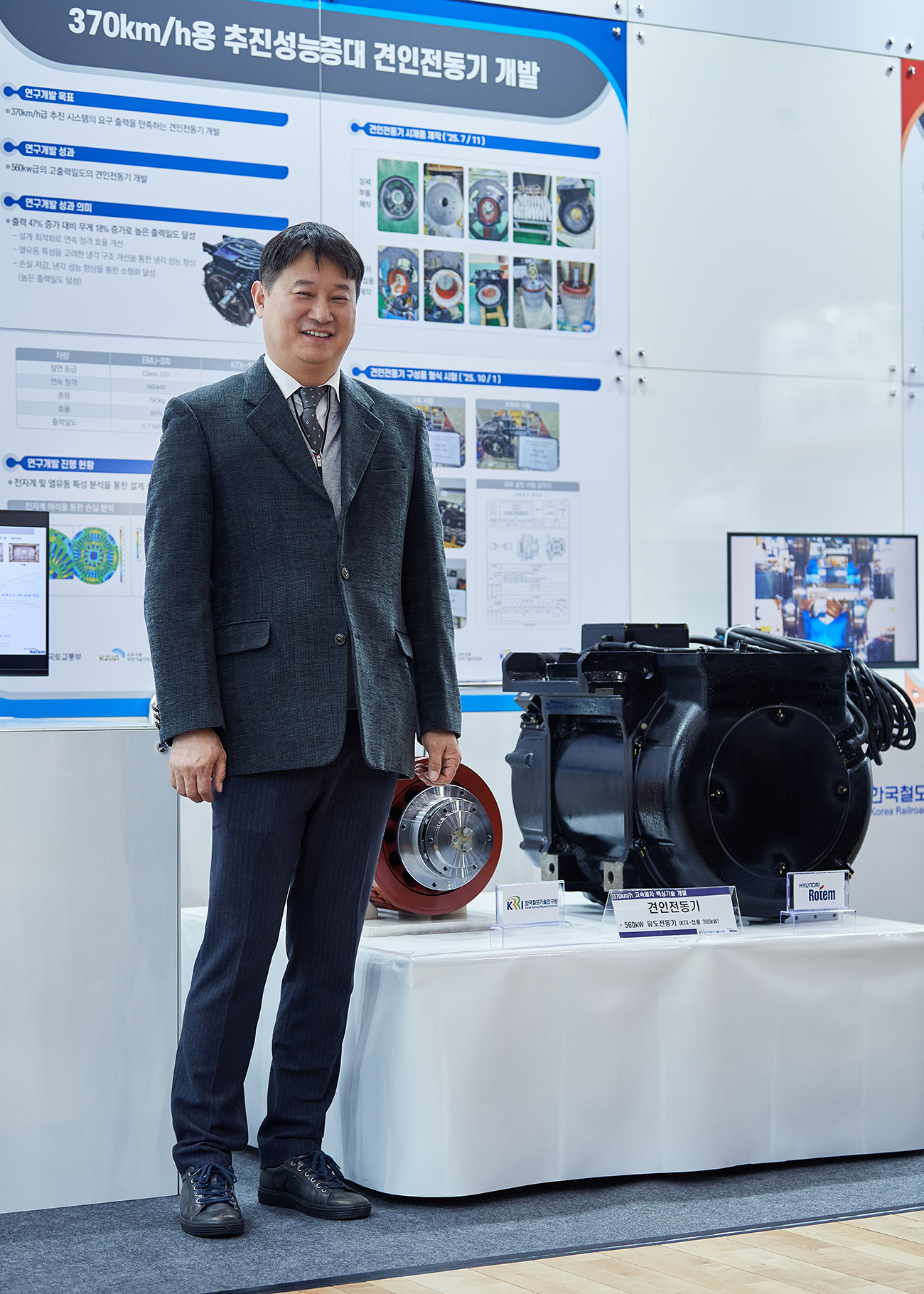

Interview: Vice President Kong Myong-sang, Hyundai Rotem RS R&D Hub, High-Speed Train(HST) & System Engineering(SE) Center

How do you feel after presenting the research achievements of the EMU-370?

The development of the EMU-370 transcended a single company project; it was a national-level, large-scale R&D initiative carried out over four years since 2022. As the R&D director, the most encouraging part was that all the goals we quantitatively set from the beginning were achieved as planned, or even exceeded. The development of core high-speed train technologies involved very strict and clear quantitative targets for each technical item. This presentation officially announces that these goals have been fully met, not only in the laboratory but also through actual driving tests and step-by-step verification. Achieving all these targets despite numerous challenges demonstrates that our technology now has world-class reliability.

I believe this is a very meaningful achievement that once again proves the strength of South Korean railway vehicle technology. Now, my goal is to ensure that these research results translate into real national innovation starting from next year through actual mass production that the public can enjoy.

What was the most technically challenging aspect of the EMU-370’s development?

The paramount hurdle was the “aerodynamic design.” As the train’s speed increases, air resistance has an exponential impact not only on energy efficiency but also on noise, vibration, and ride comfort. During development, we struggled to balance practical manufacturability with extreme future performance. For example, installing major systems as protrusions on the top makes manufacturing and maintenance much easier. However, for energy efficiency and quietness, we insisted on a “fully embedded structure.” Although there was intense coordination among the designers, we ultimately chose competitiveness in the future market, and finding that balance was the greatest technological leap.

Were there any especially difficult sub-tasks in the aerodynamic design?

Implementing the optimal nose shape (front end of the train) was the most challenging. To achieve aerodynamic performance, the EMU-370 was designed with a nose over 10 meters long. Technically, this provides the best aerodynamic performance, but at the mass production stage, it conflicts with commercial constraints such as securing enough seats in the passenger cabin or adjusting the field of view through the front window. Balancing the optimal technical performance with economic feasibility in real-world operational environments was one of the toughest challenges throughout the R&D process.

Which part of the EMU-370 best demonstrates Hyundai Rotem’s technological capability?

Undoubtedly, we place the utmost priority on optimizing NVH (Noise, Vibration, Harshness) performance. Normally, as a train’s speed increases, interior noise and ride comfort inevitably increase as well. However, the EMU-370 achieved the remarkable feat of reducing noise and vibration levels compared to previous high-speed train models, even at higher speeds. Ultimately, what matters most in a high-speed train is how quietly and comfortably passengers reach their destination. By improving indicators that passengers can directly experience, Hyundai Rotem has achieved a significant milestone with this project.

What are the most concerning or remaining challenges as commercialization nears?

There are two major challenges: “weight reduction” and “securing enough seats.” Although aerodynamic improvements have yielded approximately 7 percent energy savings, as train speeds increase, rolling stock tends to become heavier to maintain structural rigidity. Therefore, additional application of new materials and lightweight design must accompany future developments. Equally important is transportation efficiency — carrying a large number of passengers at high speeds. Addressing these two challenges will be the final key for the EMU-370 to become a game changer in the high-speed train market.

Are there any particularly memorable aspects of collaborating with the Ministry of Land, Infrastructure and Transport and Korea Railroad Research Institute?

It is the strength of the “Team Korea” model established through the EMU-370 project. The government sets the vision, research institutions conduct objective verification, and companies realize core technologies. This division of labor has been proven globally competitive. Thanks to this collaborative system, South Korea has established a solid foundation to enter overseas markets with not just rolling stock exports but also technology transfer, talent development, and local maintenance, offering a comprehensive package.

At what level is Hyundai Rotem’s actual competitiveness in the global high-speed train market?

While China develops its technology based on a huge domestic market, I believe South Korea holds a clear advantage in terms of international credibility and potential for global collaboration. Hyundai Rotem’s true competitors are traditional giants like Siemens, Alstom, and Hitachi Rail. Compared to them, Hyundai Rotem’s strength lies in combining cutting-edge high-speed running technology with distributed-traction train design and flexible package solutions. Overall, we assess that we have secured competitiveness is secured within the global top 4, and our technological pride already surpasses that.

How will the technology roadmap proceed following the EMU-370?

The core foundational technologies secured through this project will be immediately applied to future KTX successor models and performance upgrades of existing aging trains. We will not stop here. Now, we aim for 400 km/h-class technology, enhancing energy efficiency and further reducing carbon emissions. Between 2029 and 2030, we will gradually implement a roadmap to ensure that Korean high-speed trains once again achieve overwhelming technological superiority on the global stage.

Personally, how would you like to remember the EMU-370 project?

I feel that the countless on-site trials and hardships experienced during the early KTX-Sancheon days have been distilled into the highly refined EMU-370. Our railway technology has now fully left the “accumulation stage,” where we learned from others and followed behind. The EMU-370 will remain in my memory as a model that marks the beginning of a perfect and stable “technology mastery stage,” where no errors are tolerated.

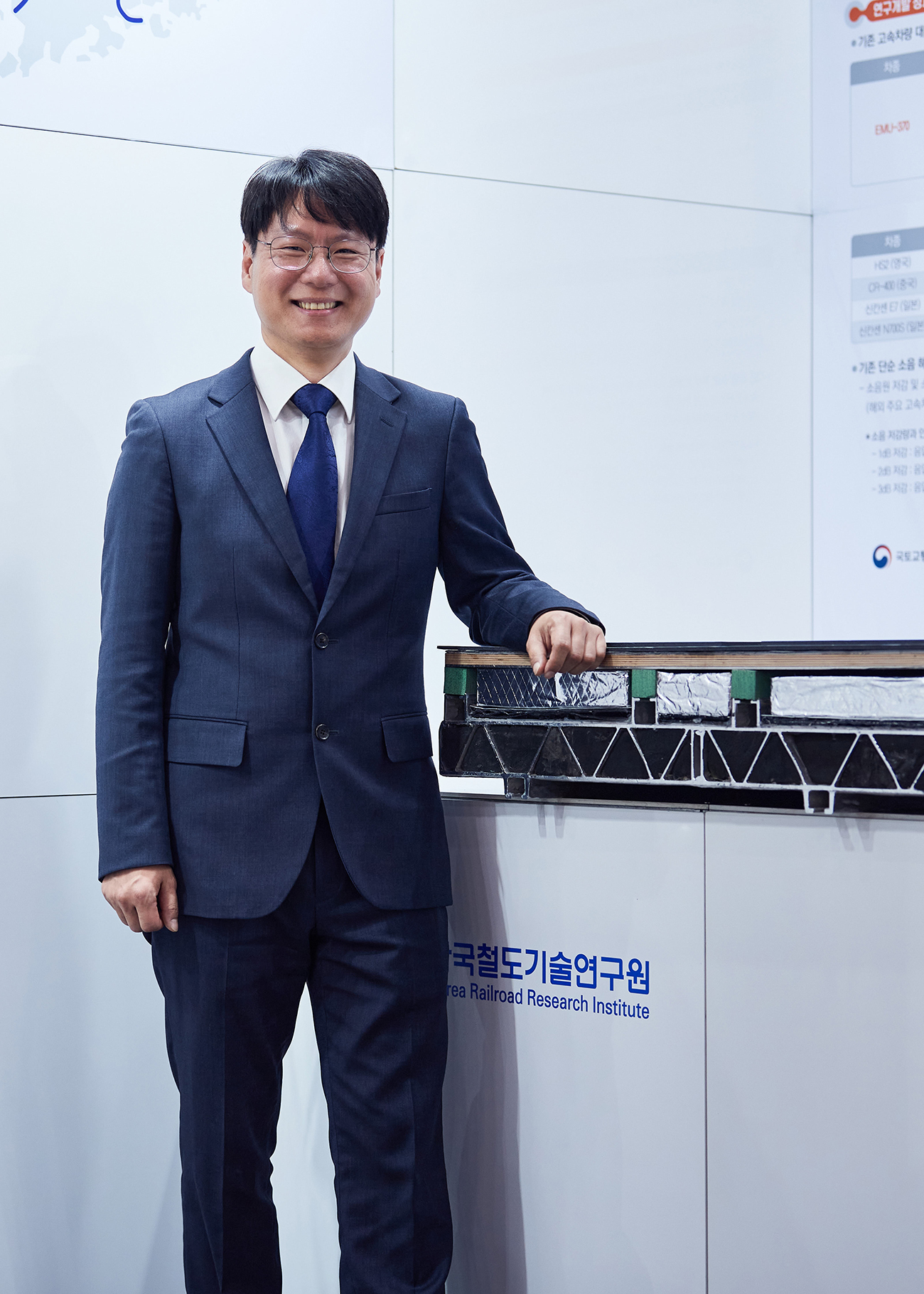

Interview: Senior Researcher Jang Hyeong-seok, Hyundai Rotem System Engineering Team

As speeds increased from 320 km/h to 370 km/h, what was the biggest technical barrier in terms of interior noise and ride comfort?

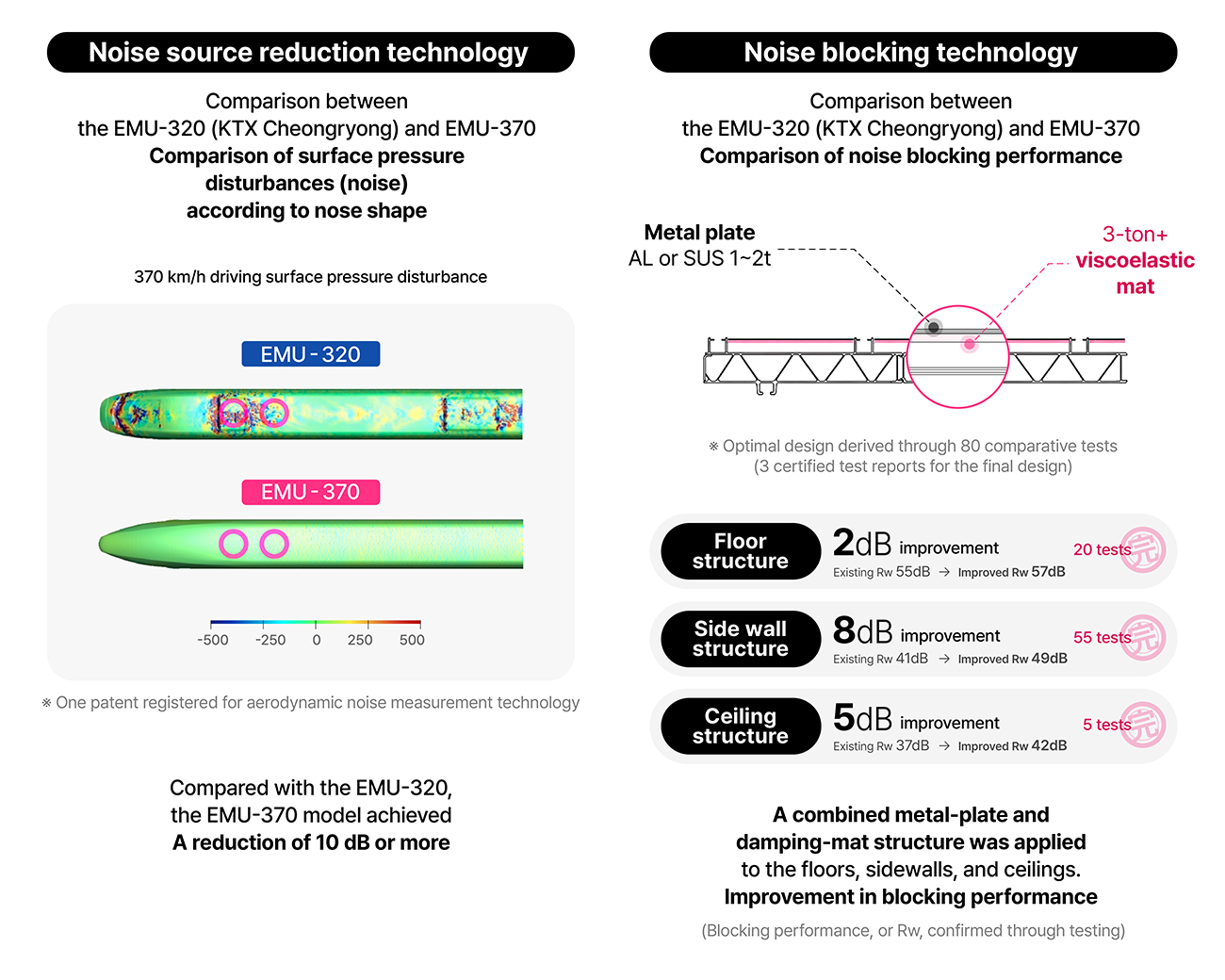

In high-speed train design, the figure of 370 km/h is not merely a 50 km/h numerical increase. Physically, noise — especially aerodynamic noise — does not increase linearly with speed. Beyond roughly 250 km/h, it rises sharply. Up to 320 km/h, existing data allowed some level of prediction, but beyond that, it was a completely new challenge.

To assess this enormous air resistance, numerous specialized surface microphone arrays were attached to multiple points on the exterior of the vehicle for aerodynamic noise measurement, and real train tests were conducted. Because the wind pressure at high speeds was so intense, some expensive sensors broke or flew off. Despite these difficult and risky conditions, actual driving data were obtained, enabling precise analysis of the mechanisms of aerodynamic noise generation. Additionally, through intense and close collaboration with designers, the optimal streamlined shape minimizing air resistance was derived.

I learned that innovative analysis methods and structures, unfamiliar in the rolling stock field, were introduced to block aerodynamic noise.

The biggest differentiator of this project was the bold application of the Transfer Path Analysis (TPA) technique — mainly used in high-performance car development — to a high-speed train. By suspending a single train car in the air and attaching over 30–40 three-directional sensors, more than 100 channels of massive data were collected. This allowed us to accurately identify the paths through which noise enters the passenger cabin. Thanks to this, we could identify previously overlooked vulnerable paths and derive improvement measures. Testing with the car body suspended is the first in Korea. Because replicating these test conditions is extremely difficult, such tests are usually only performed at the complete vehicle stage outside the domestic market.

The physical structures for blocking noise were also advanced. A “sandwich structure” was applied throughout the vehicle, layering viscoelastic materials and metal plates on top of an aluminum extrusion frame. The metal plate blocks noise with its high density and mass, while the viscoelastic material between the layers absorbs and dissipates vibrational energy internally. Through over 100 repeated experiments, the thickness and combination of materials were finely tuned, successfully achieving both sound insulation and vibration damping simultaneously.

What is the true value that the EMU-370’s NVH achievements, completed after hundreds of tests, deliver to passengers?

As engineers, paramount objective wasn’t merely loweringdecibel (dB) readings on noise meters; rather, it was enhancing passengers’ psychological sense of tranquility and the perceived quality of quietness within the cabin. Detailed analysis revealed that passengers felt the most fatigue from the low-frequency “hum” generated by traction motors.

We targeted this specific frequency band to derive design improvements, ultimately eliminating the unpleasant noises that passengers subconsciously perceived. Through extensive testing and simulation, the EMU-370’s NVH performance has evolved to a mode of transportation that guarantees a comfortable and pleasant experience even at the highest speeds, which we take great pride in. If passengers feel so comfortable that they think, “Have we already arrived?” upon reaching their destination, that is the highest praise for our researchers.

Interview: Senior Researcher Kim Jeong-cheol, Hyundai Rotem Energy Solution Development Team

Achieving a 47 percent increase in output while limiting weight gain to 18 percent is impressive. What design strategies enabled this efficient ratio?

To meet the power requirements of the 370 km/h-class propulsion system, we significantly increased the continuous rating of the traction motor from 380 kW to 560 kW. To address weight constraints that ruled out simple dimensional enlargement, we adopted two strategic design methodologies.

First, we precisely analyzed loss characteristics at each operating point, optimizing the design to minimize losses in the primary power range most used during actual operation. Improving efficiency by 1 percent reduced internal motor losses by 12.5 percent.

Second, we precisely predicted the heat generation of the stator and rotor due to increased output and designed optimal cooling channels to manage this effectively. As a result, we achieved a high power density of 0.71 kW/kg, surpassing KTX Cheongryong’s 0.57 kW/kg.

High-power traction motors inevitably generate a lot of heat. During the process of “cooling structure improvement considering thermal flow characteristics,” what aspects were emphasized?

The success of the cooling structure design depends on building an accurate thermal analysis model. The internal heat flow of a motor is highly complex; inaccurate predictions during design could result in equipment damage during actual operation.

Hyundai Rotem significantly improved model accuracy based on years of accumulated traction motor performance evaluation data. With this model, we carefully reviewed the heat generation of each key component and adjusted the shape of ventilation holes to ensure that cooling air is efficiently channeled to thermal hotspots.

After completing rigorous performance validation tests — such as locked-rotor tests and temperature rise tests — on the prototype motor, which actual performance indicator do you believe is the most competitive in the global market?

In terms of power density and efficiency, we have already reached a level comparable to leading international manufacturers. However, our most distinctive competitive advantage lies in the insulation specification that satisfies the Class 220 thermal endurance rating. To withstand the abrupt thermal fluctuations generated during high-speed operation, insulation technology is crucial. Ultimately, this means that the motor can continuously supply power without performance degradation even under extreme operating conditions.

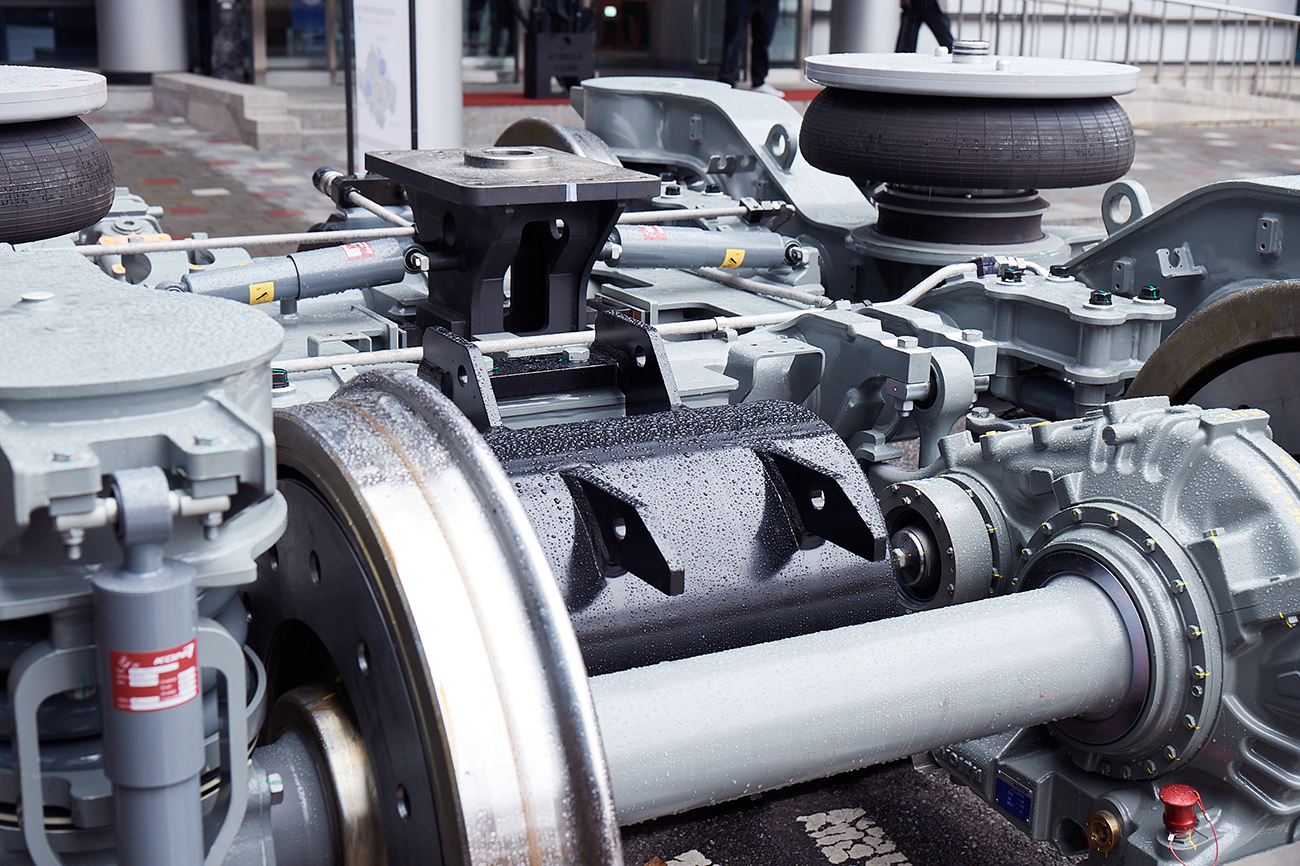

Interview: Senior Engineer Na Won-gi & Senior Engineer Park Gil-bae, Bogie System Development Team, Hyundai Rotem

At ultra-high speeds of 370 km/h, suspension systems must be “stiff” for stability, and yet “soft” for passenger comfort. When deriving the characteristic values of the suspension system (springs and dampers) to meet these conflicting requirements, what did you focus on most?

We concentrated all our efforts on building a highly accurate analytical model capable of reproducing more than 95 percent of the vibration data that an actual vehicle experiences on the track. No matter how sophisticated a design may be, if the underlying virtual model does not reflect real-world behavior, it is meaningless. We devoted significant effort to ensuring model fidelity by analyzing the vast vibration big data accumulated from existing high-speed trains.

We then applied multi-objective optimization techniques to find the optimal balance in the trade-off between “stiffness (stability)” and “softness (ride comfort).” Through this process, we derived suspension characteristics that firmly suppress bogie instability during high-speed operation while smoothly filtering out fine, high-frequency vibrations transmitted to the car body.

Unlike previous studies, this study introduced “Flexible Body” modeling to reflect even the high-frequency characteristics of car body vibration. Compared to conventional “Rigid Body” modeling, what significant differences were observed in analytical accuracy, and what was the decisive factor that enabled the error rate versus actual measured data to be reduced to within 5 percent?

Conventional rigid body modeling assumes the car body to be a single stiff mass and mainly calculates low-frequency vibrations below 5 Hz. However, the vibrations that actually cause discomfort to passengers are concentrated in the high-frequency range above 10 Hz. To address this, we decisively introduced flexible body modeling, which reflects the characteristics of a car body box structure over 20 meters long that undergoes subtle bending and twisting during operation.

Rather than simply switching to a flexible model, we repeatedly fine-tuned it by continuously comparing real driving test data with virtual simulation results. By precisely synchronizing the physical characteristics of the actual vehicle with the virtual model, we ultimately achieved a high level of accuracy, with an error rate within 5 percent compared to measured values.

The critical speed was boosted to 470 km/h — an 20 km/h improvement over the current KTX-Cheongryong — and stability without abnormal vibration was confirmed even at 400 km/h through roller rig testing. How do you see these technological advances in the running gear forming a foundation not only for the commercialization of the EMU-370 but also for the development roadmap of next-generation high-speed trains aiming for even higher speeds?

Securing a critical speed of 470 km/h and obtaining roller rig validation data at the 400 km/h class are highly significant achievements, as they demonstrate that South Korea has established a minimum technological baseline for ultra-high-speed operational stability. This achievement goes beyond research; it marks the laying of a cornerstone for a railway digital twin capable of perfectly simulating the complex variables of real operating lines in a virtual environment. Leveraging this capability, vibration issues that may arise under extreme conditions above 400 km/h can be predicted and mitigated in advance during the design stage, serving as a technical filtering mechanism.

In addition, this study clearly confirmed that passive suspension systems alone face physical limitations in maintaining ride comfort at speeds exceeding 400 km/h. This finding will serve as a key design guideline for determining the required control force and detailed specifications when implementing active and semi-active control systems, which are essential for next-generation high-speed trains.

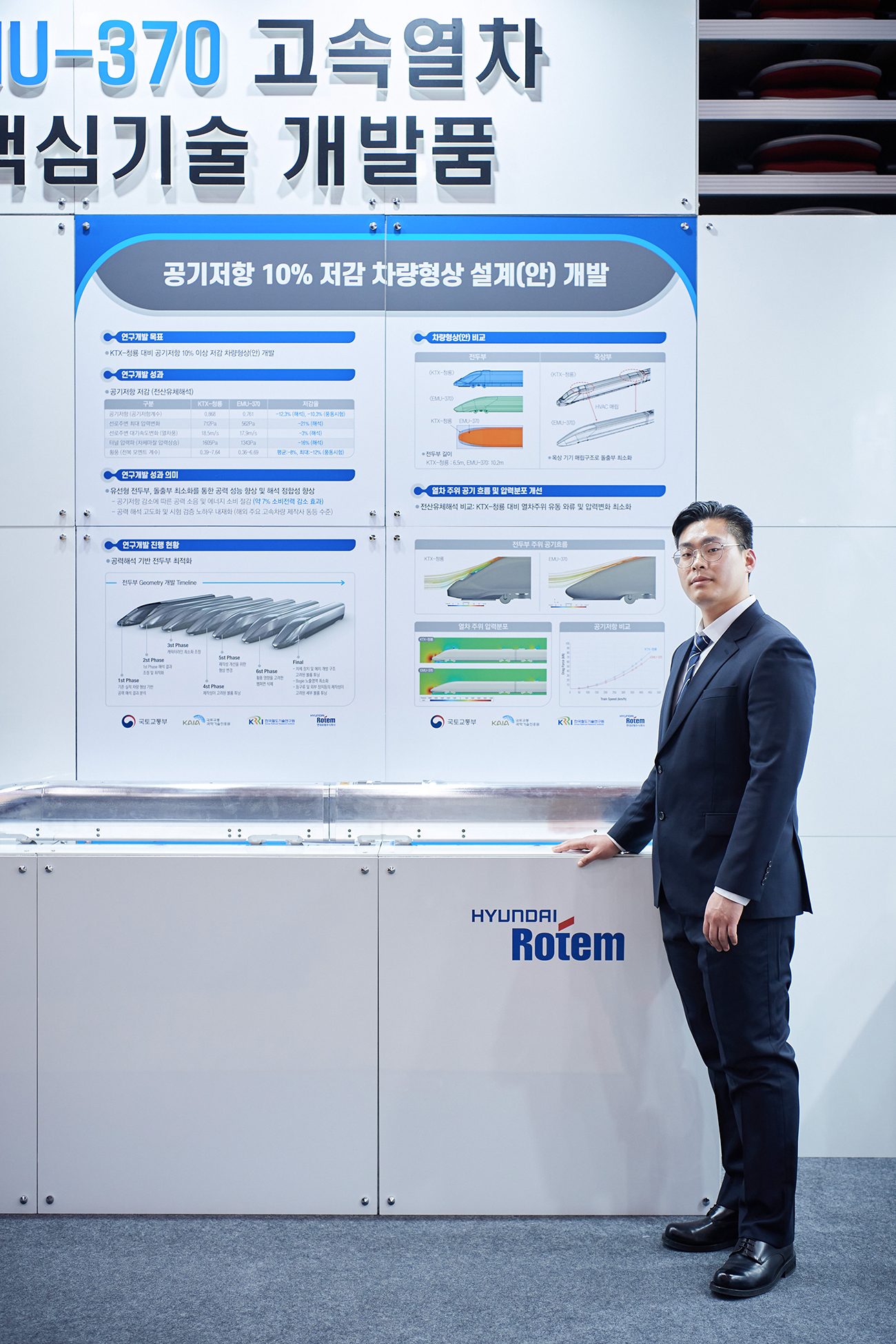

Researcher Park Gi-deuk, System Engineering Team, Hyundai Rotem

Compared to the KTX Cheongryong (6.5 meter), the nose length was significantly extended to 10.2 meter, achieving a reduction of over 12 percent in the aerodynamic drag coefficient. However, as the nose lengthens, seating arrangement and manufacturing efficiency may suffer. How did you optimize the gap between “performance” and “space efficiency?”

Extending the nose length is the most effective way to reduce aerodynamic drag, but it inevitably conflicts with passenger cabin space utilization. To address this, we conducted initial designs using an optimization analysis method that set aerodynamic drag reduction as the primary objective function.

Rather than simply lengthening the nose, we carried out a precise tuning process that took into account equipment installation feasibility, driver visibility angles, and manufacturability in real factory conditions. In particular, we focused on maximizing interior space by gently adjusting the curvature transition at the point where the passenger cabin begins.

Unlike previous trains, it was impressive how the rooftop equipment was designed within an embedded structure to minimize protrusions. In particular, embedding the HVAC system must have presented technical challenges such as maintenance accessibility and cooling efficiency. How were these issues resolved to achieve a 10 percent drag reduction?

Embedding rooftop equipment is crucial for reducing aerodynamic drag, but it presents the engineering challenge of lowering the equipment’s overall height. We approached this from two main directions. The first step was to rearrange internal components and optimize the coil design. Simply reducing the size of the evaporator and condenser coils would degrade performance, so we adopted an inclined coil layout that lowers the installation angle. This increased the horizontal projected area, maintaining cooling efficiency while reducing the overall HVAC height from 580 mm in the KTX Cheongryong to 480 mm — a full 100 mm reduction.

Second was ensuring maintenance convenience. Considering that embedded equipment may decrease accessibility, we optimized filter sizes and designed them in a modular, segmented structure. As a result, we were able to reduce energy consumption by lowering aerodynamic drag while delivering an efficient system that enables field engineers to perform maintenance more easily.

Through this research, Hyundai Rotem has internalized advanced aerodynamic analysis and validation know-how, earning evaluations that it now possesses technology on par with major global high-speed train manufacturers. Wind tunnel tests and analytical results showed high accuracy, matching within about 10 percent. How will this precise design capability become a unique competitive advantage as the EMU-370 enters the global market?

To enter the global market — especially advanced railway markets such as Europe — manufacturers must clear the stringent hurdle of the EU’s Technical Specifications for Interoperability (TSI). The TSI require extremely detailed aerodynamic performance criteria, including pressure variation, train-induced wind speed, tunnel pressure waves, and crosswind stability.

The aerodynamic analysis technologies internalized during the EMU-370’s development have reached a level where these stringent requirements can be accurately predicted and verified from the design stage onward. Hyundai Rotem is now confident that it has secured a unique aerodynamic design competitiveness beyond manufacturing, enabling customized responses to global market demands.

The Future Trajectory Envisioned by Hyundai Rotem

The technological achievements demonstrated by the EMU-370 — breaking the 370 km/h barrier — go far beyond simply building a faster train. They mark a turning point that shifts the global railway market paradigm from “catching up” to “leading,” and, as Vice President Kong Myong-sang described it, represent a victory for Team Korea, built collectively by the domestic railway industry ecosystem.

Behind this project’s success were the relentless efforts of researchers who battled invisible aerodynamic resistance and carried out tens of thousands of simulations to achieve optimal ride comfort. All of these innovations deliver safe and comfortable mobility for the public while nationally elevating South Korea’s status as a powerhouse in railway rolling stock technology. Hyundai Rotem is now looking towards tomorrow. The foundational technologies secured through the EMU-370 are expected to serve as a solid cornerstone for the future development of 400 km/h-class ultra-high-speed trains