Just over 30 years ago, Hyundai Rotem was receiving European high-speed train manufacturing technology transfers. The Rail Solution R&D Center played a pivotal role in transforming the company into a true global game-changer through high-speed train localization, overseas market expansion, and successful commercialization of the Greater Seoul Metropolitan Area GTX and Hydrogen Fuel Cell Trams.

The Rail Solution R&D Center oversees research and development across Hyundai Rotem’s railway business division, from complete rolling stock to core components and systems including propulsion system, bogies, and signaling systems. Executive Vice President Lee Won-sang joined the company in 1992 and held key positions including Leader of Bogie Development Team, Head of System Engineering Division, and Head of Core Technology Development Division, successfully leading the development of Hydrogen Fuel Cell Trams. Since 2023, he has spearheaded research and development of railway vehicles and systems as head of the Rail Solution R&D Center.

We met with Executive Vice President Lee Won-sang at RailLog Korea to explore what has driven Hyundai Rotem’s remarkable growth and what future the company envisions ahead.

What is the key message Hyundai Rotem wants to convey at this year’s Korea Railways & Logistics Fair?

“When we decide to participate in an exhibition, we carefully consider clear themes and core messages. The large hydrogen society diorama positioned at the center of this year’s Hyundai Rotem booth provides a significant clue. Our first theme emphasizes that building a hydrogen ecosystem is as important as developing eco-friendly trains powered by hydrogen energy.”

“In reality, building the hydrogen ecosystem isn’t something Hyundai Rotem pursues alone. It’s a major project at the Hyundai Motor Group level, involving numerous group companies and partners. Hydrogen production, storage, transportation, and subsequently refueling infrastructure and diverse hydrogen mobility solutions will populate the hydrogen society.

At this year’s Korea Railways & Logistics Fair, we wanted to convey our ambition to serve as a company capable of providing comprehensive hydrogen mobility solutions within this vast ecosystem.

Our second core theme focuses on high-speed trains. In the past, train manufacturing often relied on imported components. While this might establish you as a train manufacturer, all the added value flows out of Korea to overseas markets. To transform this industry landscape, Hyundai Rotem is working closely with Korean domestic partners to localize all core components including bogie, propulsion system, TCMS (Train Control and Management System), and signaling systems.

Following localization, we’re pursuing overseas expansion not as Hyundai Rotem alone, but as an industry consortium. The exhibits on the left side of our booth showcase core components for the 250km/h power distributed high-speed trains that we successfully contracted last year for deployment in Uzbekistan.

Hyundai Rotem plans to pursue global market expansion more aggressively with Korean high-speed trains localized within our Korean railway industry network.

Finally, we wanted to showcase both Hyundai Rotem’s present and future to visitors. Previously, we often displayed mockups created for events, but this year we brought our most advanced vehicles that Hyundai Rotem has been developing over the past two years – vehicles on the verge of mass production. These three vehicles – the Airport Railroad EMU, Korea, Taoyuan Green Line EMU, Taiwan, and Edmonton Tram, Canada – have completed all testing phases and will soon enter commercial service.”

Returning to Korea Railways & Logistics Fair after two years, what changes do you see compared to then?

“If Hydrogen Fuel Cell Trams represented the future two years ago, today we can say they’re already an ongoing reality. At Korea Railways & Logistics Fair 2023, we first unveiled pre-commercial Hydrogen Fuel Cell Trams. The most significant progress since then is winning the Daejeon Urban Railway Line 2 hydrogen tram project with design work now underway. We also recently secured a contract for hydrogen trams that will operate on the Ulsan Taehwagang Station to Jangsaengpo section starting in 2027.

Also, the Australian NIF double-decker EMU we exhibited two years ago has successfully entered commercial operation. That vehicle was also showcased at InnoTrans 2024 in Germany last year, receiving acclaim from countries worldwide and subsequently leading to a 2.2027 trillion won contract for Morocco double-decker EMUs. This confirmed that exhibitions can indeed lead to actual business contracts”

Looking around the exhibition, the Busan Train Express(BuTX) also draws considerable attention. What significance does the BuTX project hold for Hyundai Rotem?

“BuTX is currently undergoing private investment project eligibility review. If the project proceeds and Hydrogen powered cars are adopted for BuTX, I believe this alone will create a major paradigm shift in the global train market. This is because Hydrogen powered cars are truly the first of their kind worldwide. It’s literally the ultimate hydrogen train being introduced. Hydrogen powered cars represent the pinnacle of hydrogen mobility technology, and we’re confident that no hydrogen train anywhere in the world possesses a more powerful performance than what Hyundai Rotem has designed.

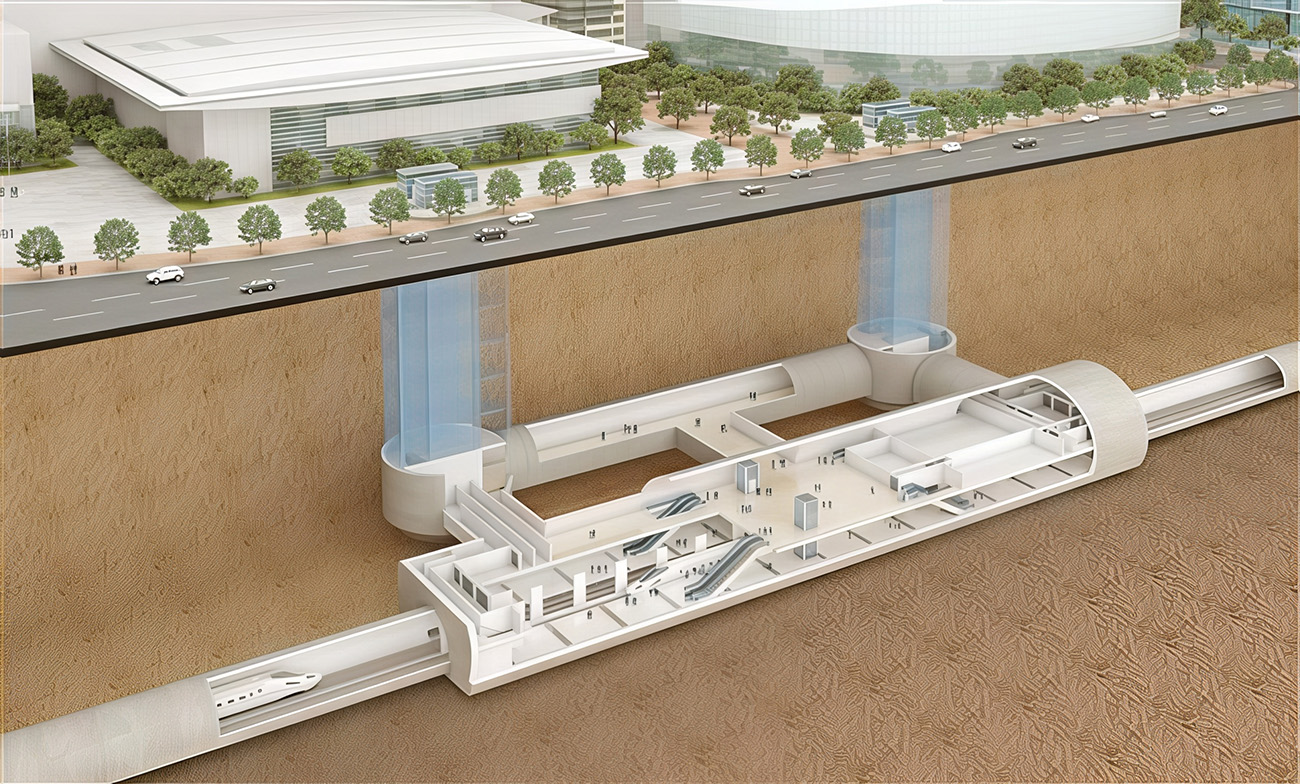

While hydrogen trains offer environmental benefits, they can also significantly reduce tunnel size by eliminating infrastructure like overhead catenary systems. For BuTX, which connects Busan from east to west between Gadeokdo New Airport and Osiria Tourism Complex, infrastructure construction costs can be dramatically reduced. Smaller tunnel sizes reduce construction costs, and the elimination of power supply facilities such as overhead lines, substations, and transformers provides tremendous project cost advantages. This is why we see it as having strong potential as a private investment project.”

What stage is Hyundai Rotem’s Hydrogen powered car development at?

“We have completed the conceptual design phase. The Hydrogen powered car miniature model exhibited this time represents our original design concept. As you can see, the hydrogen storage tanks are mounted on the roof, which presents maintenance challenges. Given the hydrogen fuel cell specifications at the time of design, that configuration was optimal.”

“However, the development of flat-type hydrogen fuel cell stacks has significantly advanced our design capabilities. Flat-type hydrogen fuel cells are more compact than previous hydrogen stacks, providing more space within the vehicle. As a result, the design has been modified to stack hydrogen storage tanks at the rear of the vehicle. The miniature model shows four hydrogen cell packages, each comprising two hydrogen fuel cell stacks. However, the Hydrogen powered car for BuTX will include two additional auxiliary hydrogen fuel cell stacks for a total of 10, and per trainset, there will be 20 hydrogen fuel cell stacks and 10 hydrogen cell packages installed. This is made possible by implementing flat-type hydrogen fuel cells.”

“The power output is sufficient to operate up to 160km/h in deep underground tunnels 40 meters or more below ground, and can exceed 200km/h when operating above ground. If operating speed is limited to 150km/h, it becomes possible to extend from the current four passenger cars to six, eight, or more cars. This flexibility allows us to adapt to changing operational requirements, whether it calls for increased passenger capacity or higher speeds. Another highly attractive advantage is the scalability to various concepts such as hydrogen tram-trains or hydrogen freight trains, provided hydrogen infrastructure is available.“

The more you explain, the greater the significance of the BuTX Hydrogen powered car becomes.

“Exactly. If Hydrogen Fuel Cell Trams were our first step toward the hydrogen mobility roadmap, then Hydrogen powered cars represent the ultimate hydrogen mobility achievable with current Hydrogen Fuel Cell Tram technology. Moreover, many cutting-edge technologies from GTX are extensively incorporated, with core technologies such as aerodynamics and pressure-tight design fundamentally applied for deep underground operation.

In terms of energy, it delivers the highest power among current hydrogen-powered mobility solutions. In the automotive sector, hydrogen trucks represent the highest-power hydrogen mobility currently available, equipped with one fuel cell set from Hydrogen Fuel Cell Trams – that’s two hydrogen fuel cells. In contrast, the Hydrogen powered car for BuTX incorporates 10 fuel cell stacks, arithmetically delivering five times the power of hydrogen trucks’ two fuel cell stacks. Since this is a power car configuration with locomotives at both ends of the passenger cars, it produces up to 10 times the power of hydrogen trucks.”

The emergence of flat-type hydrogen fuel cells seems to have brought significant advances to Hyundai Rotem’s hydrogen train development. Can this system be freely adjusted to meet vehicle performance requirements?

“This is a crucial concept. The flat-type hydrogen fuel cell you’re seeing is also the most space and energy-efficient fuel cell globally. Since it’s already standardized for mass production, achieving higher output simply requires modular stacking. No more optimized system exists among hydrogen fuel cells released to date.

The hydrogen locomotive that Hyundai Rotem has been developing as a national project with the Korea Railroad Research Institute since 2024 targets an even higher output of 3MW. Currently, we need to stack 200kW-class fuel cell sets, but dedicated high-output fuel cell systems would be more efficient. For example, if we develop 1MW-unit fuel cell mass production systems in the future, we could simply use three 1MW units instead of stacking 15 sets of 200kW fuel cells. 1MW-class hydrogen fuel cells won’t be limited to hydrogen locomotives but can be applied to various sectors including hydrogen ships and power plants in the future.“

What is Hyundai Rotem’s future roadmap for railway mobility?

“This exhibition aimed to showcase our hydrogen mobility development roadmap, and as you can see today, we have development plans extending from Hydrogen Fuel Cell Trams to low-floor hydrogen EMUs. This directly utilizes Hydrogen Fuel Cell Tram technology, making it a vehicle ready for immediate commercialization.

You can also look forward to the hydrogen locomotive currently under development as a national project. Upon completion, we expect it to be a 3MW-class vehicle capable of hauling freight trains, replacing existing diesel locomotives all together. Also, last year’s high-speed train supply to Uzbekistan marked our first export of Korean high-speed trains, and this milestone opens the door to a future where Hyundai Rotem’s high-speed trains expand globally to Central Asia, African regions like Morocco, Eastern Europe, Vietnam, South America, and beyond.”

Finally, is there something you’d like to emphasize through this exhibition?

“I want to emphasize that Hyundai Rotem will grow together with our partners. While visitors may focus solely on the achievements of complete rolling stock, I hope they don’t overlook that the core components inside were localized through collaboration with domestic partner companies. Both our highest-performance hydrogen trains and high-speed vehicles that have successfully entered the global market are proud achievements developed together with korean partners. Moving forward, Hyundai Rotem will continue working tirelessly for joint overseas expansion through strategic collaboration and co-development with Korean small and medium enterprises(SMEs) in a consortium structure.”

‘A future of growing together’. This phrase that Executive Vice President Lee Won-sang shared at the end of our interview, despite having to hurry away due to his busy schedule, was brief yet deeply resonant. While everyone speaks of sustainability, companies that demonstrate a sustainable future as tangible reality through technological innovation are rare. Through Executive Vice President Lee Won-sang, we confirmed that Hyundai Rotem is faithfully fulfilling its promise to ‘create a sustainable future with advanced mobility that connects the world.