Hyundai Rotem has unveiled its next-gen railway technologies and products at ‘RailLog Korea 2023’ held at Busan BEXCO. Korea Railways & Logistics Fair is the largest railway exhibition in Korea, where innovative technologies and products for both domestic and foreign railway industries are introduced. RailLog Korea 2023 was the 11th event to be held for this exhibition fair.

Hyundai Rotem has drawn significant interest by unveiling its flagship models and new advanced technologies as the company showcased the biggest booth in the exhibition among all participants. Hydrogen mobility is the ultimate alternative for the carbon neutral era and is one of the future core businesses of Hyundai Rotem and its first commercial model of a hydrogen fuel cell tram drew the most interest throughout the entire event. Let’s take a look at the presence of Hyundai Rotem at RailLog Korea 2023 where innovative technologies and products that will lead the future of the railway industry were unveiled.

Hydrogen fuel cell tram Revealed for the First Time to General Public and the Hydrogen Ecosystem Envisioned by Hyundai Rotem

The ‘hydrogen fuel cell tram’ at the center of the ‘H2 TECH FLOW Zone’ drew the most attention at the Hyundai Rotem booth. It is a next-gen eco-friendly transportation method integrating hydrogen, which is drawing interest as an eco-friendly power source in the mobility market, into public rail transportation, and it is also a model that became the first domestic railway industry product to win the main prize at the ‘iF Design Award 2023’, which is one of the top three reputable design awards in the world, in Germany back in May.

▶ Go to ‘Hyundai Rotem’s Hydrogen Fuel Cell Tram Recognized for its Value at the Global Design Awards

The design is outstanding, but it also offers outstanding functionality and eco-friendliness. The hydrogen fuel cell tram has the effect of purifying approximately 800㎍ (micrograms) of fine dust while also generating 107.6kg of clean air per hour.

Especially at RailLog Korea 2023, the hydrogen fuel cell tram drew interest from even more visitors as the exhibit allowed visitors to actually see the tram model and visitors were even able to board and take a look inside the tram. This exhibition offered a special experience where visitors can board the hydrogen fuel cell tram that is drawing even more anticipation and interest ahead of its upcoming operation in Ulsan during the second half of this year.

An even wider hydrogen infrastructure and hydrogen production technology must be prepared to build a hydrogen society utilizing a wider variety of hydrogen trains beginning with the hydrogen fuel cell tram. To achieve this vision, Hyundai Rotem is developing liquid hydrogen engine trains to implement hydrogen energy across the rail industry while also building the hydrogen infrastructure by building hydrogen fueling stations and the Hynet Hydrogen Shipping center to produce hydrogen by extracting hydrogen from natural gases and to supply hydrogen fuel.

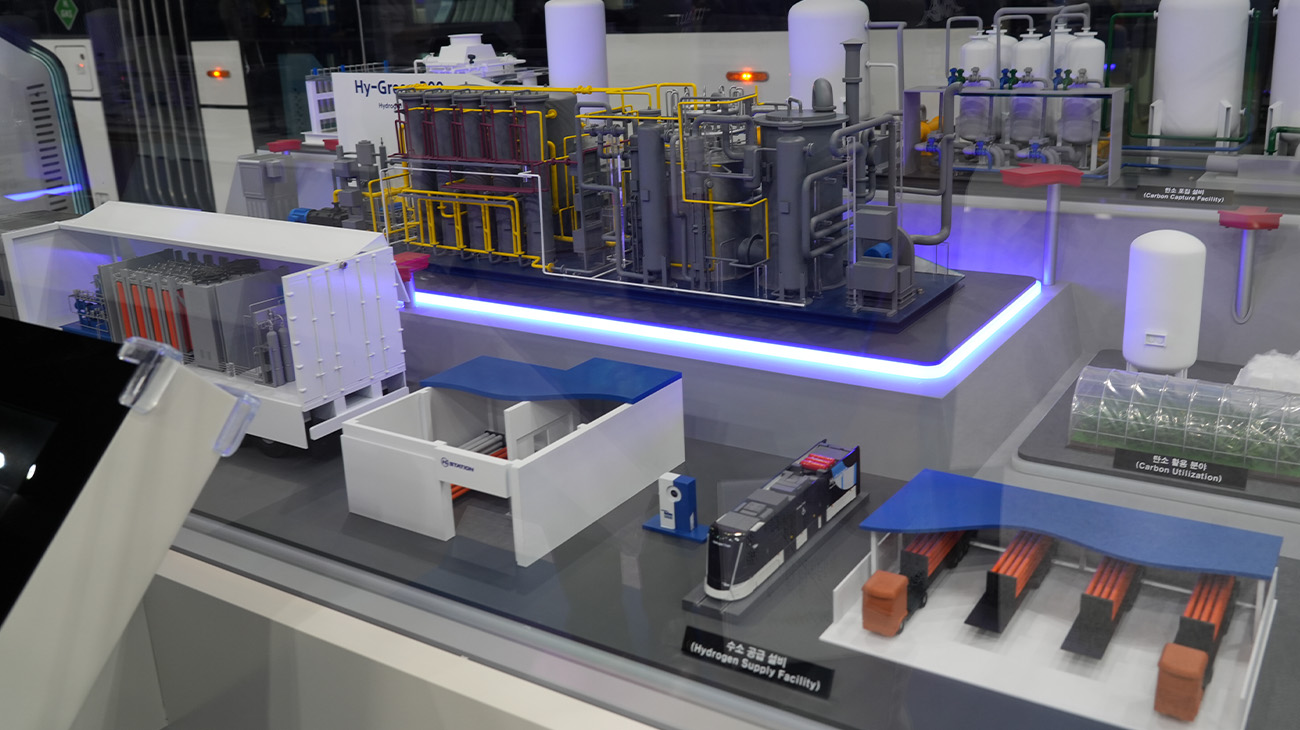

Hyundai Rotem has also unveiled the ‘Mobile Fuel Cell Power Station’, which allows hydrogen fuel to be utilized in various locations and the visual model of the ‘Resource Circulation-type Clean Hydrogen Infrastructure’. The Mobile Fuel Cell Power Station will serve as an alternate eco-friendly power supply using hydrogen in locations that previously used large power generators such as construction sites, concerts, and event sites, while also being utilized as mobile power generators that supplies power to mobility solutions such as electric vehicles and ships, and it offers a solution to locational and spatial restrictions while also expanding the optimal hydrogen infrastructure across more locations.

Also, a diorama displaying the Resource Circulation-type Clean Hydrogen Infrastructure envisioned by Hyundai Rotem showed that the hydrogen infrastructure envisioned by Hyundai Rotem had the ‘effect of greenhouse gas emission reduction’ as the hydrogen vehicles did not produce any air pollutants throughout the process of production, storage, transport, and utilization, and the ‘effect of improving air quality’ by purifying air pollutants such as fine dust, nitrogen oxides, and carbon monoxides. And unlike the power plants consuming fossil fuel to produce electricity, this model suggested that you could expect the ‘effect of reduced resource consumption’ by directly producing electricity. The intent and technological capabilities of Hyundai Rotem to build the ultimate eco-friendly energy production environment with reduced carbon emission were especially noticeable with the development of the ‘carbon collector device’, which solves the issue of increasing carbon emission during the hydrogen production process.

Safe infrastructure equipment and its stable operation are essential for changing the public perception of hydrogen charging equipment still being dangerous. Hyundai Rotem is planning to build an integrated hydrogen control system utilizing the digital twin technology in an effort to change such perception. Reliability and safety for hydrogen fuel cell tram and hydrogen infrastructure were secured through this system by applying the ‘condition based maintenance (CBM)’ technology.

▶ Go to ‘Hydrogen control system using a digital twin’

Korea Train Control System (KTCS) Assisting in Safe and Convenient Train Operation

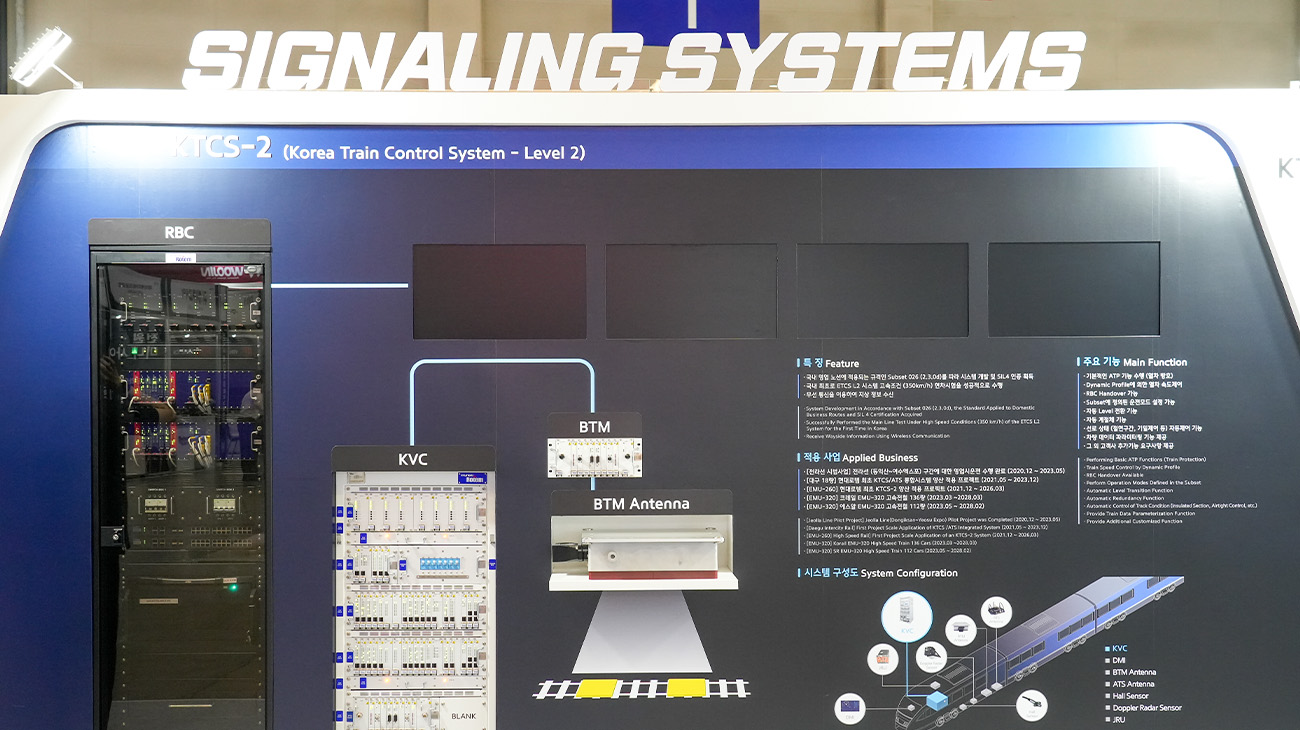

Also, there was a space where you could see the ‘Korea Tran Control System (KTCS)’ which improves railway safety and efficiency. This train signal system, divided into KTCS-M, KTCS-2, and KTCS-3 categories, is a key system for train operation which executes speed control and track switch to prevent train collision/crash and derailing.

The ‘KTCS-M System’ is a system that safely controls the trains through consecutive bi-directional data communication between the train and the ground control center using the railway wireless communication method (LTE-R) or Wi-Fi on the ISM bandwidth for the Korea Train Control System. It can operate all levels of automated operation including the unattended train operation (UTO), so it allows efficient operation of the urban railway.

The KTCS-2 system is an ATP device meeting the specifications for LTE-R communication-based train control system in Korea. With this system standardizing the domestic train signal system, a signal system compatible with all domestic lines can now be constructed. The KTCS-2 system has currently finished development and its performance is being verified through the pilot operation in a sector across 180km between Iksan Station to Yeosu EXPO Station, and the system will be applied across other lines in the future. Also, the KTCS-2 system can be utilized across domestic lines as well as the lines in Europe and other regions as it meets the level 1 and level 2 standard specifications for the European Train Control System (ETCS), so it offers a promising future in terms of exports as a technology assisting in safe operation and management of trains.

The ‘KTCS-3’ system is the latest train signal system technology and it is an integrated ATP/ATOP vehicle on-board system that meets the standard European railway specifications by only using the LTE-R wireless communication instead of a track circuit in a high-speed rail operating environment. It supports GoA 2 and offers real-time train tracking and adjustment of train intervals to offer improved line efficiency and railway transport capabilities compared to the ETCS L2 system. Also, it can operate simultaneously with the existing ATP (ETCS Level 1) system and the KTCS-2 system that is currently underway for large-scale application, which leads to anticipation for effects such as improved operational capabilities and minimization of ground equipment.

▶ Go to ‘Definition and technology trend of train signaling system

Also, at the booth introducing the integrated network system to be applied in the GTX-A line, you could see the smart maintenance and repair system applied across the operation, maintenance, and repair of railway vehicles by implementing the Fourth Industrial Revolution technologies such as the Internet of Things (IoT) information and communication technologies (ICT). Such systems including the KTCS, systematically collect and analyze the status information of trains and major devices to assist in more efficient and stable operation of trains.

Hyundai Rotem has considered the domestic communication environment to change charge in developing a railway system to assist in efficient railway operation such as the digital maintenance and repair platform based on the ethernet communication network system, real-time status monitoring, and big data analysis that can be applied across various types of rail vehicle such as high-speed trains, EMUs, and trams.

▶ Go to ‘Assuring safety and operation efficiency with a smart technology, Hyundai Rotem’s condition-based maintenance (CBM) system

AR-VR Experience Zone Offering Special Train Experience

The ‘AR-VR Experience Zone’ was an experience zone that was one of the most popular places among visitors. Visitors can directly assemble, observe, or even drive the trains and trams through VR headsets and joysticks, and the zone provided a unique experience via virtual reality.

You can also experience the maintenance and repair training contents utilizing augmented reality developed by Hyundai Rotem. You can scan the QR code on model components to load 3D models for the actual part and learners can freely observe the 3D model displayed in the tablet PC. Through this process, you can inspect over 10 parts including the journal box, speed detector, and springs, and information such as inspection records and cycles for each part are displayed to offer improved learning effects.

▶ Go to ‘Virtual Convergence Technology Contents from Hyundai Rotem Supporting Even Safer and Efficient Training

You could see the innovative technologies and products that will lead the future of the railway industry from Hyundai Rotem at RailLog Korea 2023. This was an event where you could see how Hyundai Rotem will apply its high competitiveness in the next-generation railway market as the company is quickly growing its hydrogen mobility capabilities as hydrogen draws attention as the ultimate alternative solution for the carbon neutral era. And this is why there is even more anticipation concerning the future of the sustainable railway industry created by Hyundai Rotem.